Which Excavator Electrification Method Is Better? Comparing Dual Powertrain vs. Diesel Generator-Powered Electric Systems

Converting a diesel excavator to electric operation involves balancing power needs, flexibility, weight, and cost. Let’s break down your two proposed options and evaluate which is better and why, based on technical feasibility, operational practicality, cost, and customer usage patterns.

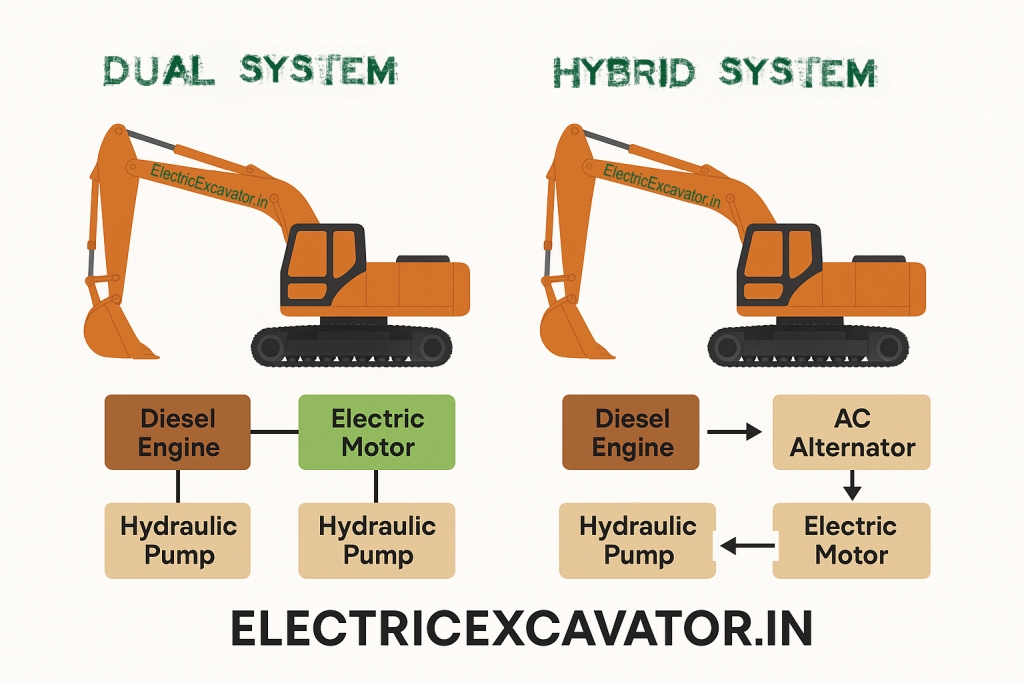

⚙️ Option 1: Dual Powertrain System (Diesel + Electric Separate)

✅ Description:

- 2 separate systems:

- Original diesel engine + hydraulic pump (retained as-is).

- Added electric motor + separate hydraulic pump for electric operation.

- Operator can switch between diesel or electric modes.

- Diesel used for traditional use or when no electric power source is available.

🔍 Pros:

- Redundancy: If electric system fails or no power is available, diesel can continue operation.

- Flexible deployment: Can operate in remote areas without charging infrastructure.

- Minimal disruption: Easier for customers who are transitioning slowly to electric solutions.

❌ Cons:

- Heavier and more complex: Two powertrains = more weight, space constraints, and design complexity.

- High cost: Two pumps, two power sources, more electronics and hydraulics = higher installation and maintenance cost.

- Energy loss: Dual system could introduce inefficiencies (more lines, more valves).

⚡ Option 2: Diesel Generator + Electric Motor Drive (Series Hybrid Concept)

✅ Description:

- Diesel engine runs a permanently coupled AC alternator, which powers the electric motor that runs the main hydraulic pump.

- The entire excavator runs on the electric motor only, regardless of energy source.

- When electricity from grid or battery is unavailable, diesel alternator starts and powers motor (generator mode).

🔍 Pros:

- Single hydraulic system: Electric motor always drives the hydraulic pump = simplified mechanical system.

- Cleaner & modular: Retrofitting is easier and only one hydraulic pump is needed.

- Easier maintenance: Fewer moving parts on the hydraulic side (no switching between two pumps).

- More energy-efficient than full diesel in urban or idle-heavy environments.

❌ Cons:

- Less redundancy: If electric motor or control system fails, machine is out of service (unless a battery backup is installed).

- Limited mobility without diesel: If grid power is unavailable and diesel generator isn’t running, excavator cannot move.

- Diesel usage still required for mobility in off-grid locations unless fully battery-powered.

🔧 Comparison Table

| Feature | Option 1: Dual System | Option 2: Diesel Gen + Electric Motor |

| System Complexity | High (2 pumps & control systems) | Moderate (1 pump, 1 motor) |

| Weight | High | Lower |

| Flexibility | Very High (can run on diesel anytime) | Medium (diesel alternator required) |

| Cost | High | Medium |

| Maintenance | Difficult | Easier |

| Conversion Feasibility | Complicated | Relatively simpler |

| Power Redundancy | Yes | Limited |

| Suitable for remote sites | Yes | Yes (if diesel generator is on) |

| Preferred for urban work | No (loud, polluting) | Yes (can run electric quietly) |

🔍 Which Option Is Better?

✅ Recommendation: Option 2 is better for most modern applications.

Why?

- More streamlined, efficient, and easier to operate.

- Retains diesel only for backup power generation, not for primary drive.

- Reduces weight, complexity, and dual maintenance.

- Ideal for construction sites looking to reduce emissions and meet regulatory standards.

However, Option 1 is better only if:

- You need 100% redundancy,

- Customers operate in very remote areas with no power infrastructure, and

- They want to continue using diesel at will.

🧠 Final Suggestion:

If you are making a product for future-focused clients or urban contractors, go with Option 2 (diesel alternator + electric drive) — it’s hybrid, cleaner, modular, and scalable. But offer Option 1 for clients needing full dual-mode assurance.

🛠️ Heavy-Duty Excavator Buckets Built to Last

We manufacture high-performance excavator buckets using resist wear plates and high-strength teeth, engineered for extreme durability and maximum penetration. Our buckets are designed to handle the toughest materials — from rock and gravel to demolition debris — while reducing downtime and increasing efficiency.

Ideal for all major excavator brands and customizable to suit your site-specific needs.

🔧 We Modify All Types of Excavators to Electric Power!

Whether it’s JCB, Tata Hitachi, Hyundai, Volvo, CAT, Komatsu, Kobelco, or any other model — we provide reliable and efficient electric conversion solutions.

📞 Contact Us for Bulk Port Handling Solutions

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.GrabsIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Strength, Precision, Reliability – Elevate Your Port Operations

genuinely serving since 1969. 🚀🔥

- cat

- diesel electric excavator

- diesel to electric conversion

- electric excavator retrofit

- electric motor excavator

- excavator conversion solution

- excavator electrification

- excavator hydraulic system

- excavator powertrain options

- generator powered excavator

- hybrid excavator

- Hyundai

- JCB

- Kobelco

- komatshu

- Tata Hitachi

- volvo