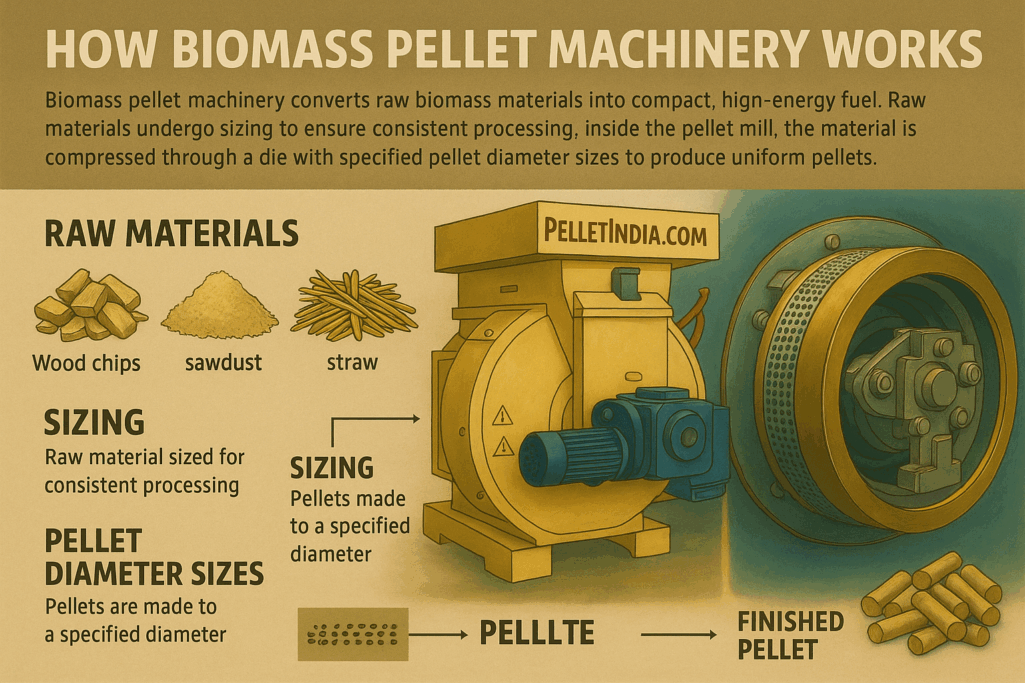

🌿 How Biomass Pellet Machinery Works: From Raw Material to Finished Pellet

Biomass pellet machinery is engineered to convert organic agricultural and forestry waste into compact, high-energy pellets used in residential, commercial, and industrial heating applications. The process involves mechanical size reduction, moisture control, compression, and post-processing, transforming loose biomass into a fuel-efficient, standardized form. ✅ Step-by-Step Pellet Production Process ✅ Key Plant Machinery 📏 Raw Material […]

Why You Need a Conditioner for Your Pellet Mill?

The Difference Between Cold and Warm Climate Operations Understanding the Role of a Conditioner in Pellet Production In pellet manufacturing, especially for biomass and wood pellets, a conditioner is a key component placed before the pellet mill. It pre-heats the raw material (usually with steam), softens fibers, and activates lignin — the natural binder — […]

What are the advantages of using a dual track horizontal ring die pellet mill?

🔧 Dual Track Horizontal Ring Die Pellet Mill – Technical Overview ✅ Definition A Dual Track Horizontal Ring Die Pellet Mill features a horizontally mounted ring die with two compression rollers (dual track), offering increased efficiency, throughput, and extended usable die surface. ⚙️ Technical Specifications Feature Specification / Description Die Type Ring Die – Horizontal […]

⚠️ Beware of Undersized and Low-Capacity Biomass Wood Pellet Machines! 🚨

Many Indian manufacturers are misleading buyers by selling undersized and low-capacity pellet machines, which creates a negative impact on the industry and genuine suppliers. Since 1969, PelletIndia.com has been a trusted supplier of biomass pellet plants and machinery. Our goal is not just to supply machines but to ensure the complete setup and commissioning of […]

❓Which type of pellet mill best suits your production needs? 🔥🤔

Flat Die Pellet Mill vs. Ring Die Pellet Mill – Detailed Comparison & Ranking 🔥⚙️ Feature Flat Die Pellet Mill 🟠 Ring Die Pellet Mill 🏆 🔧 Design Flat die with downward roller pressure Rotating ring die with internal rollers ⚡ Capacity Lower (50 kg/h to 1 TPH) Higher (1 TPH to 5 TPH+) 🔋 […]