Introduction

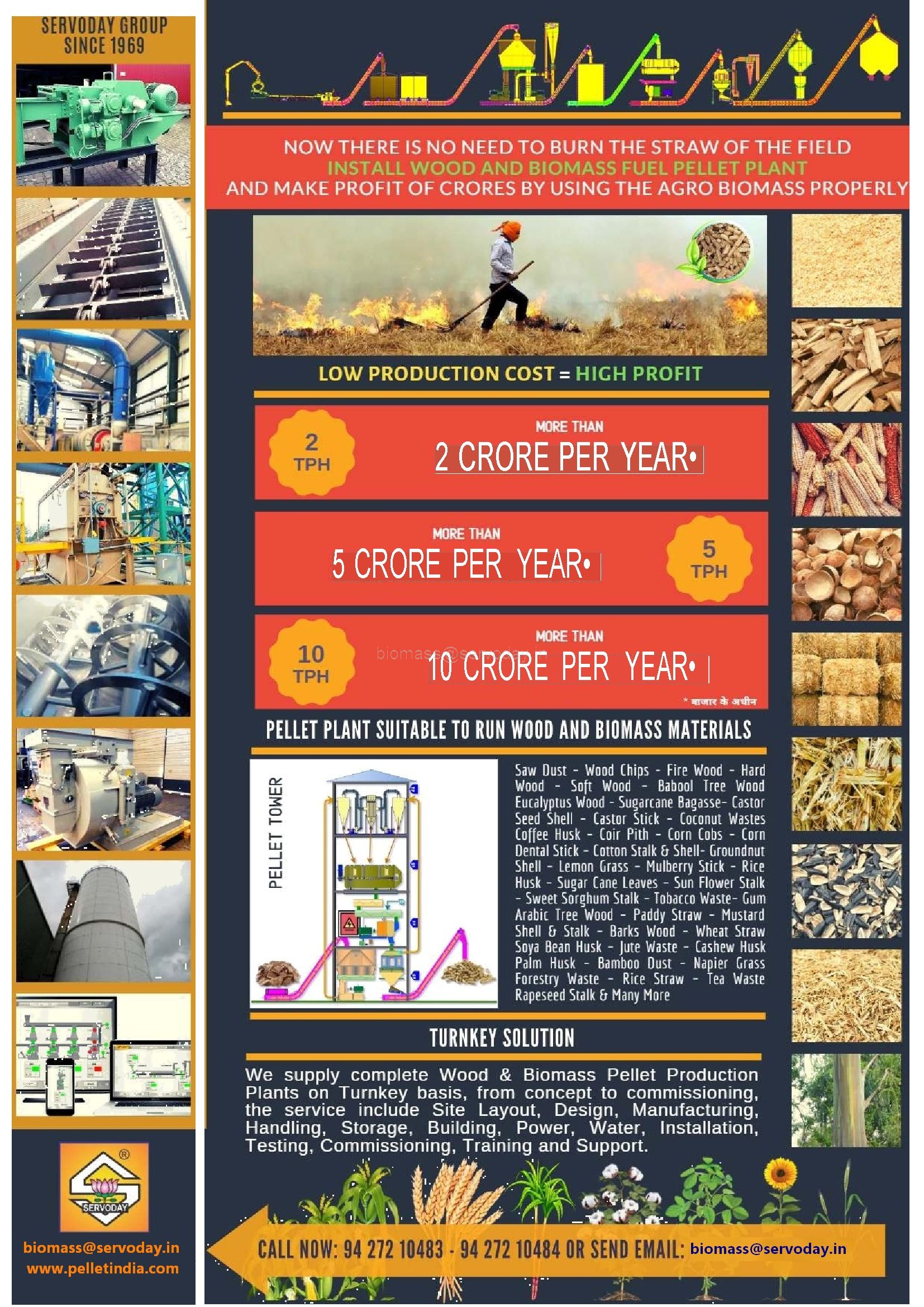

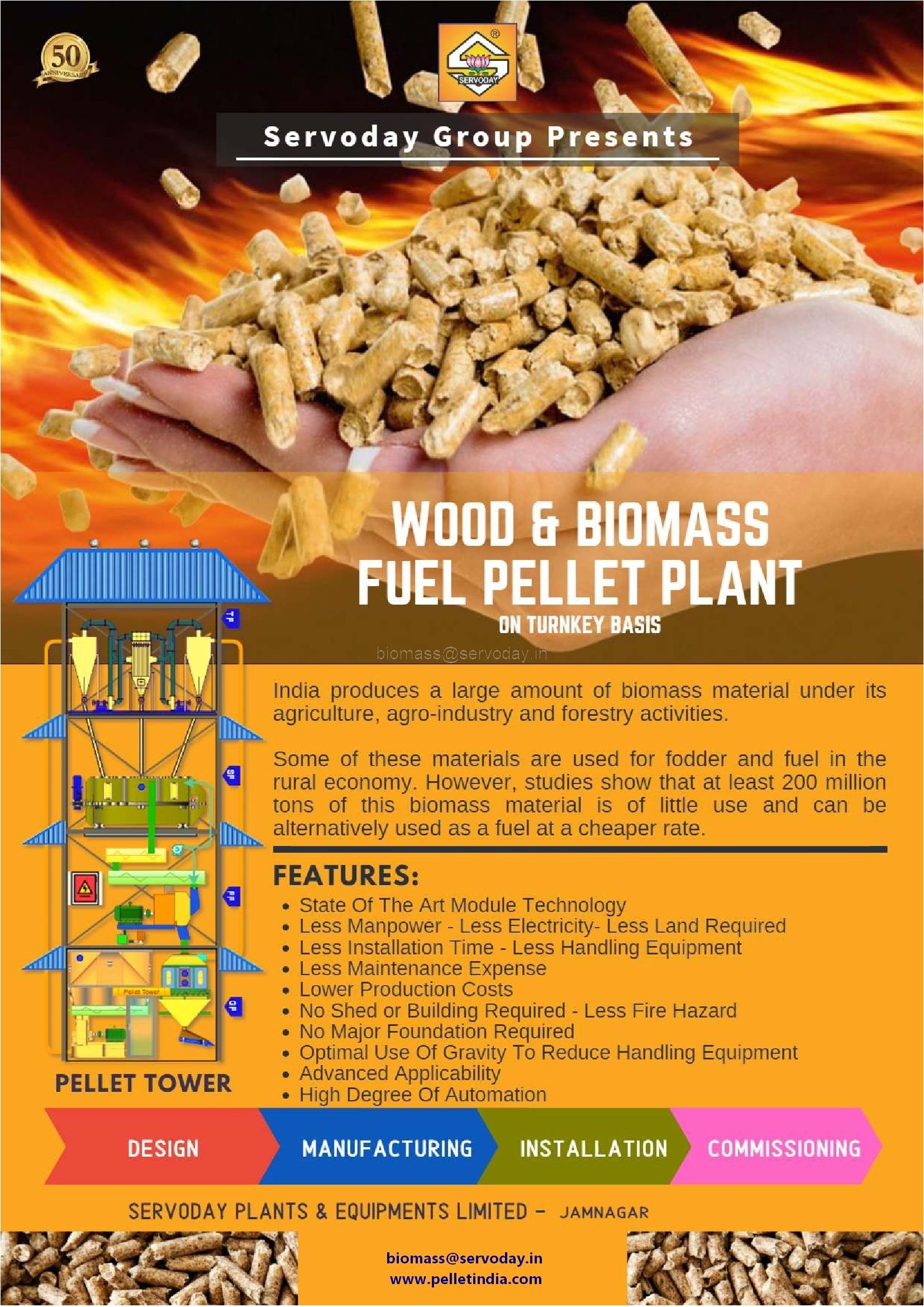

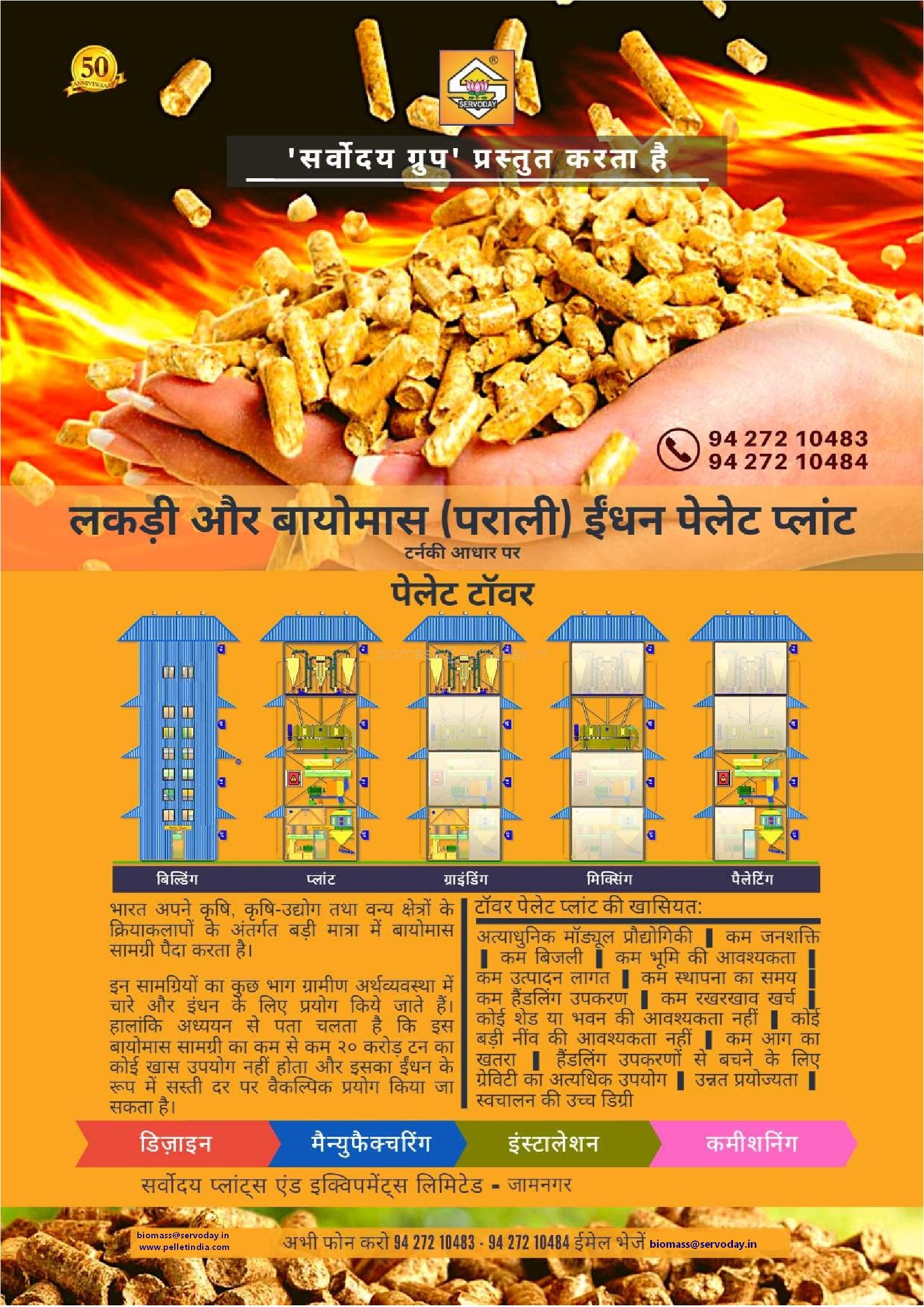

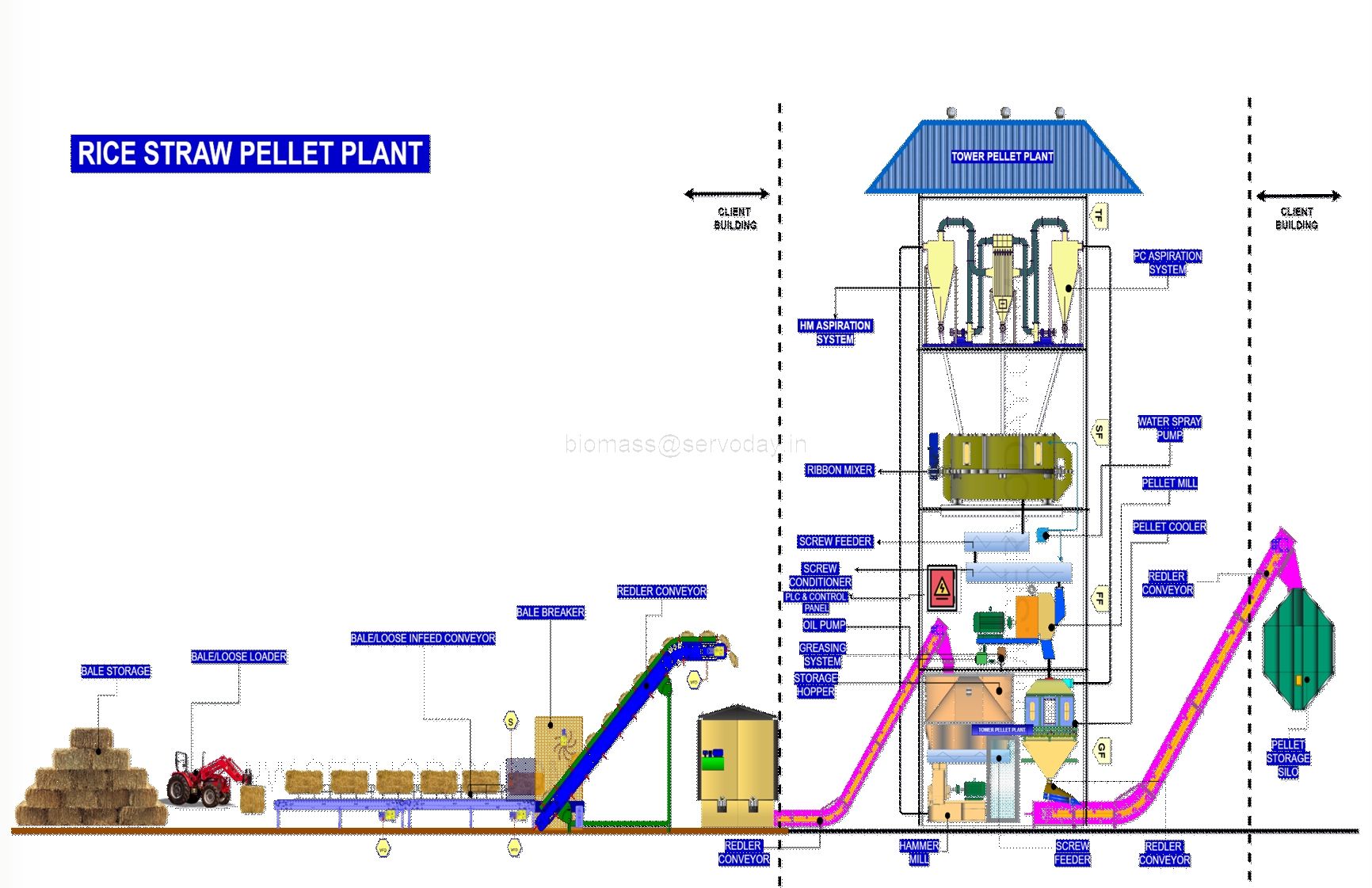

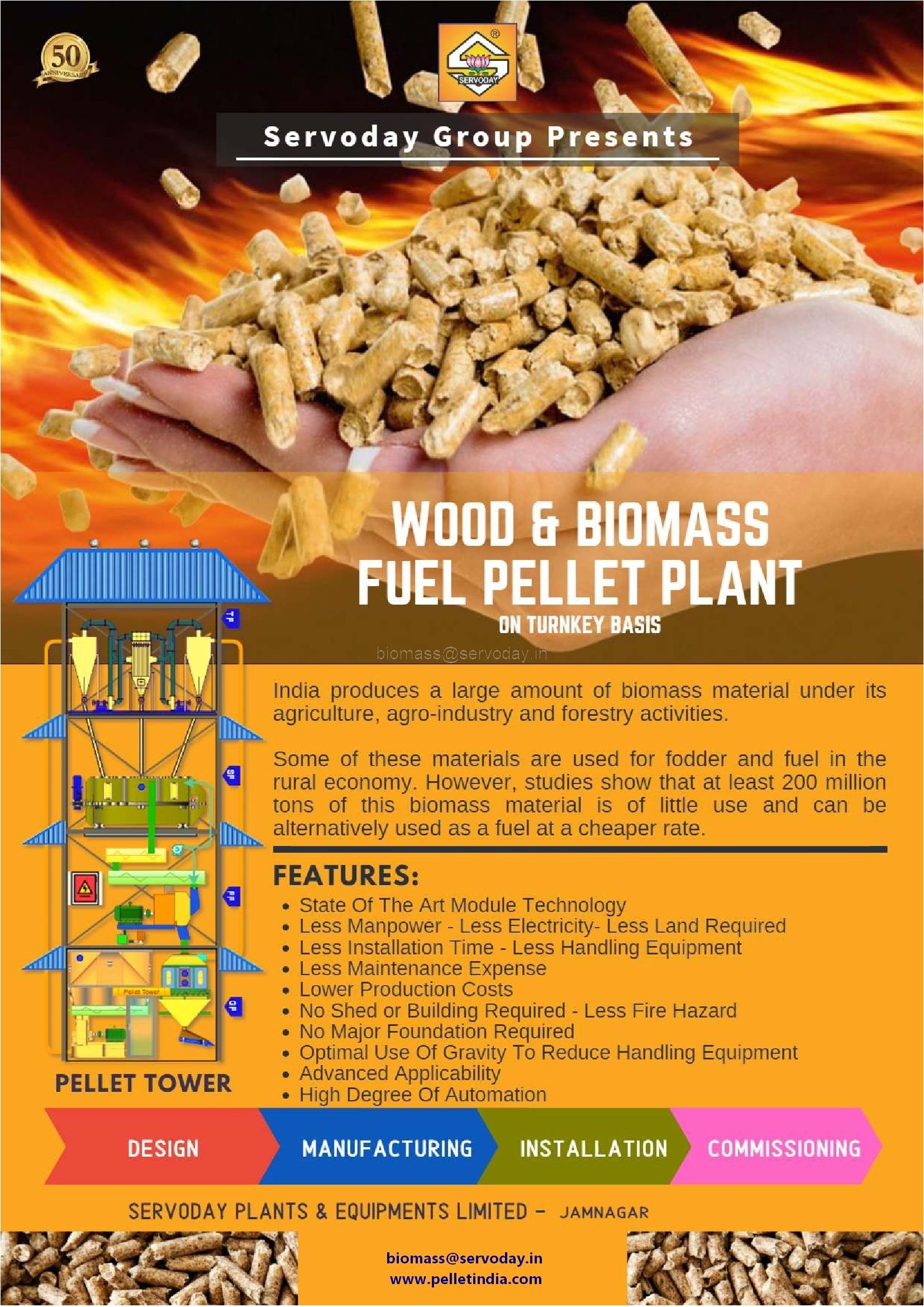

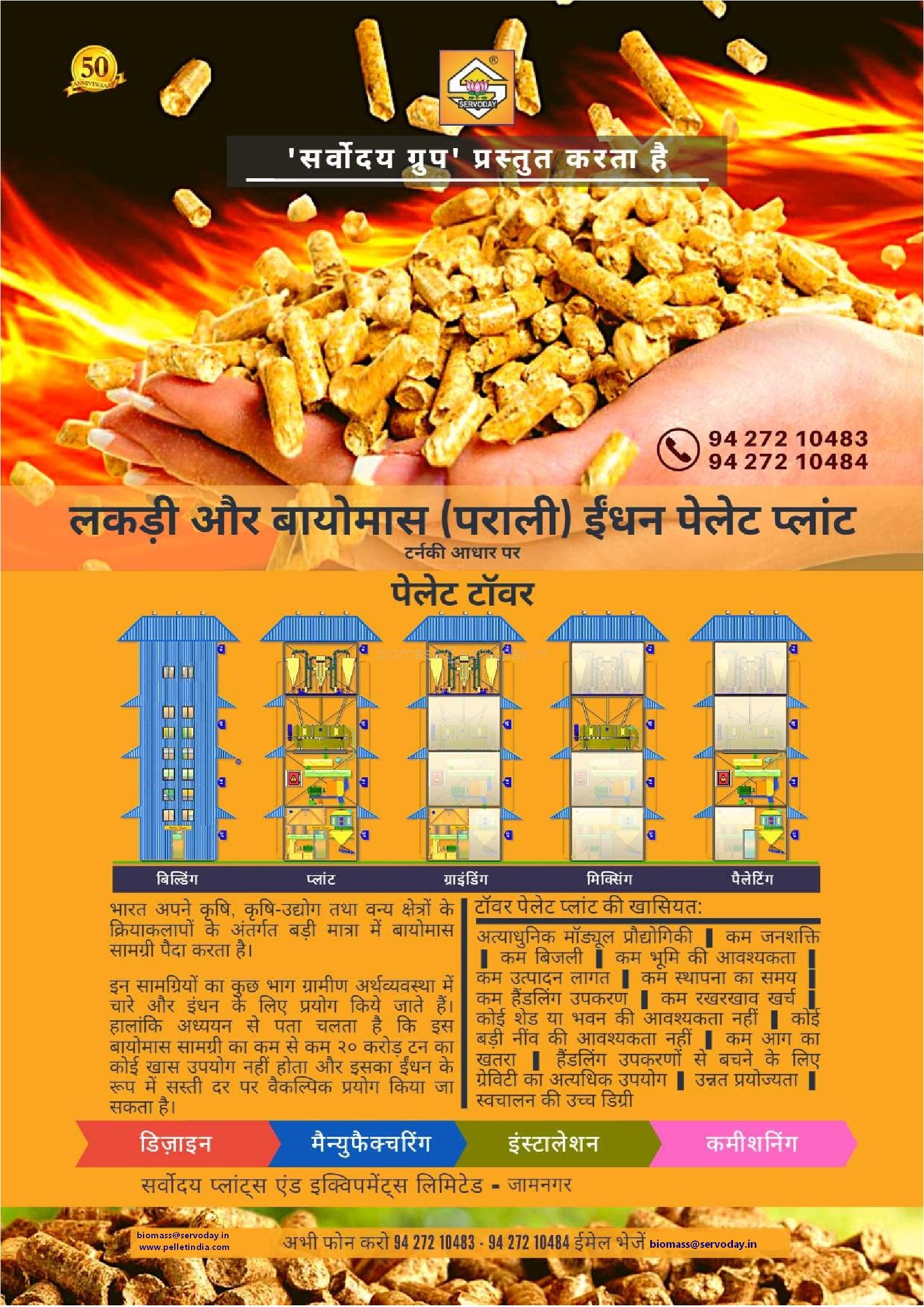

The Wood Biomass Tower Pellet Plant is an innovative, space-efficient biomass processing facility that utilizes a vertical design. It is specifically engineered for producing biomass pellets from various raw materials, optimizing production capacity while minimizing land usage. This design makes it an ideal solution for urban and space-constrained environments.

Overview

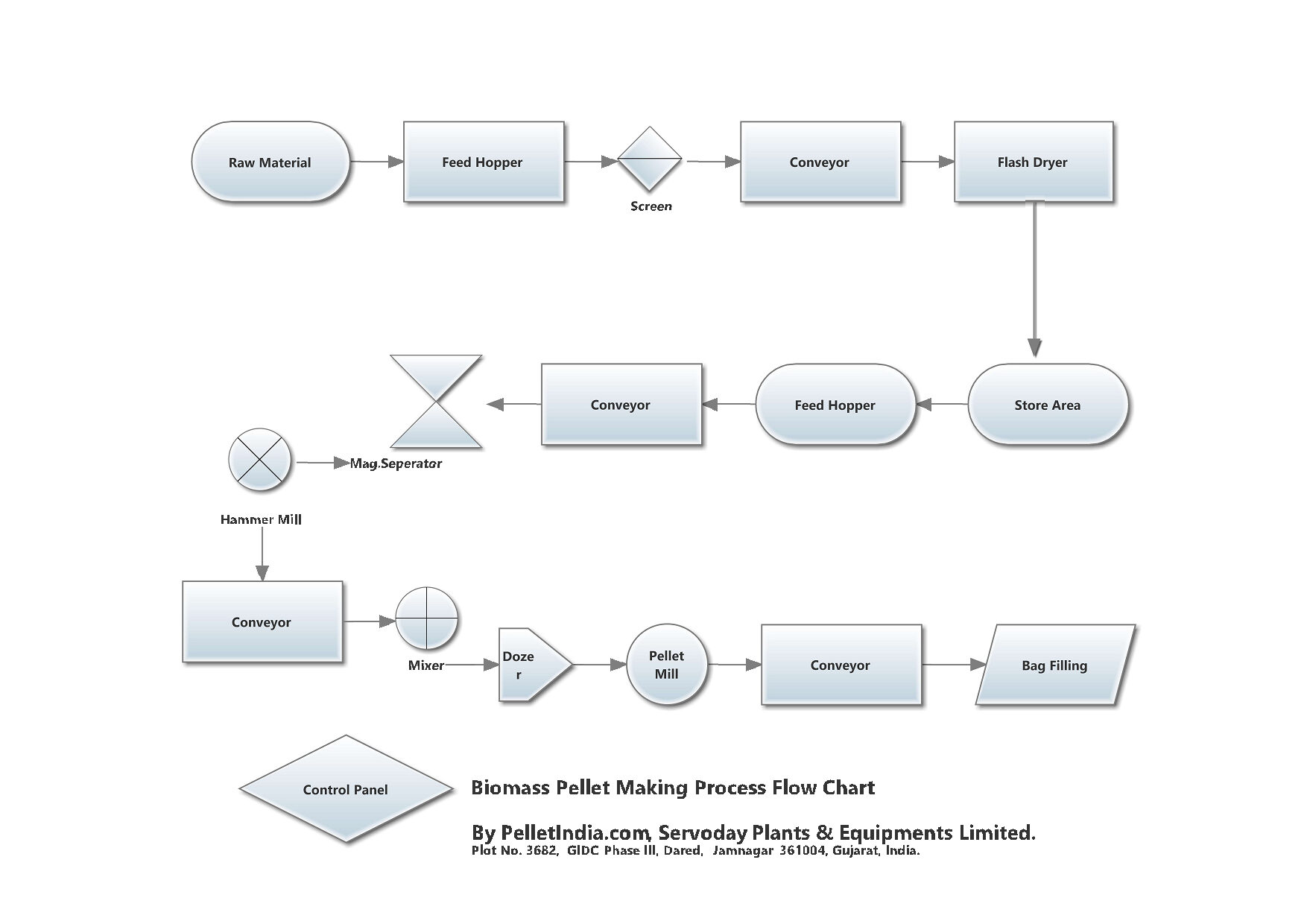

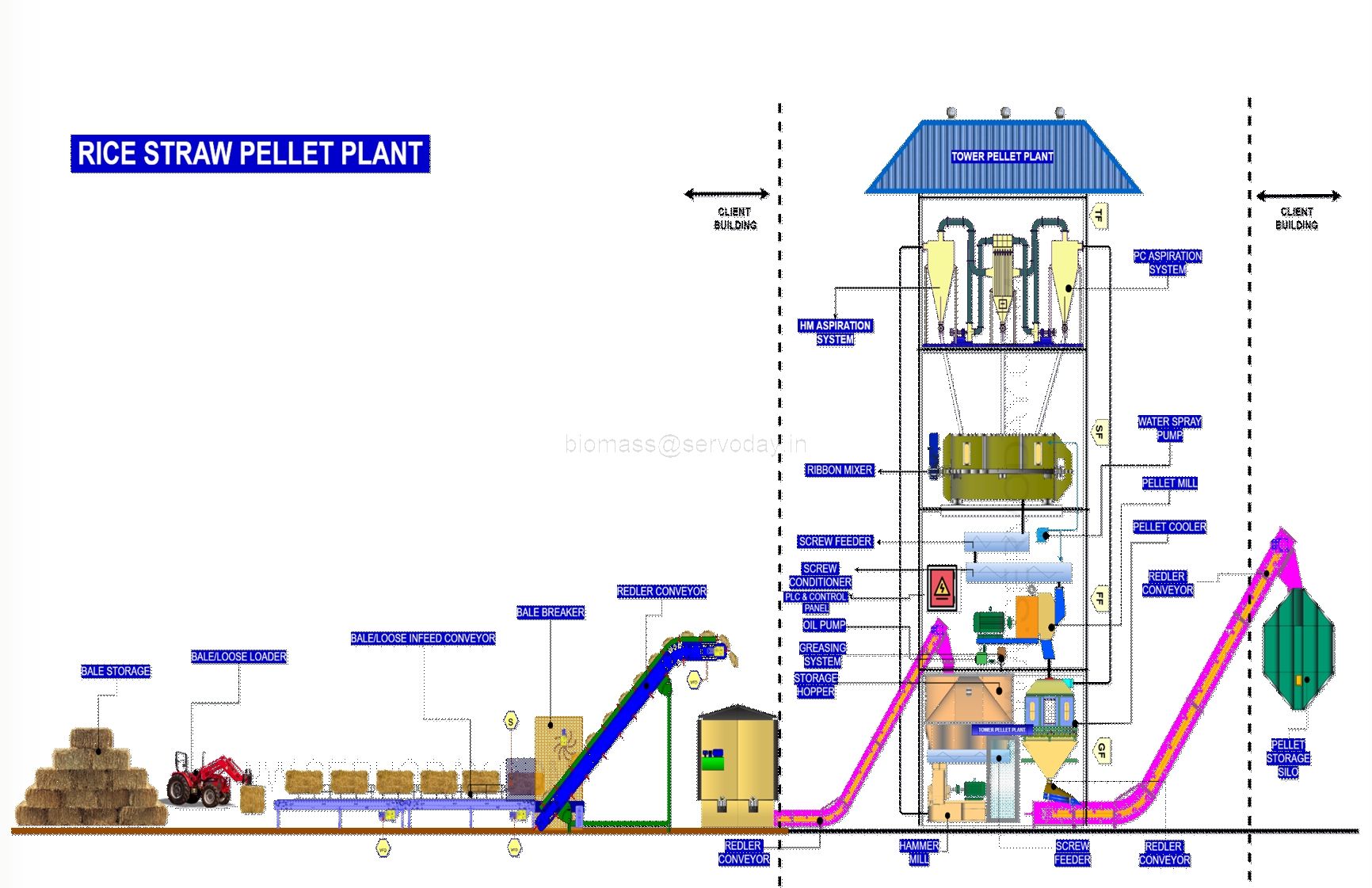

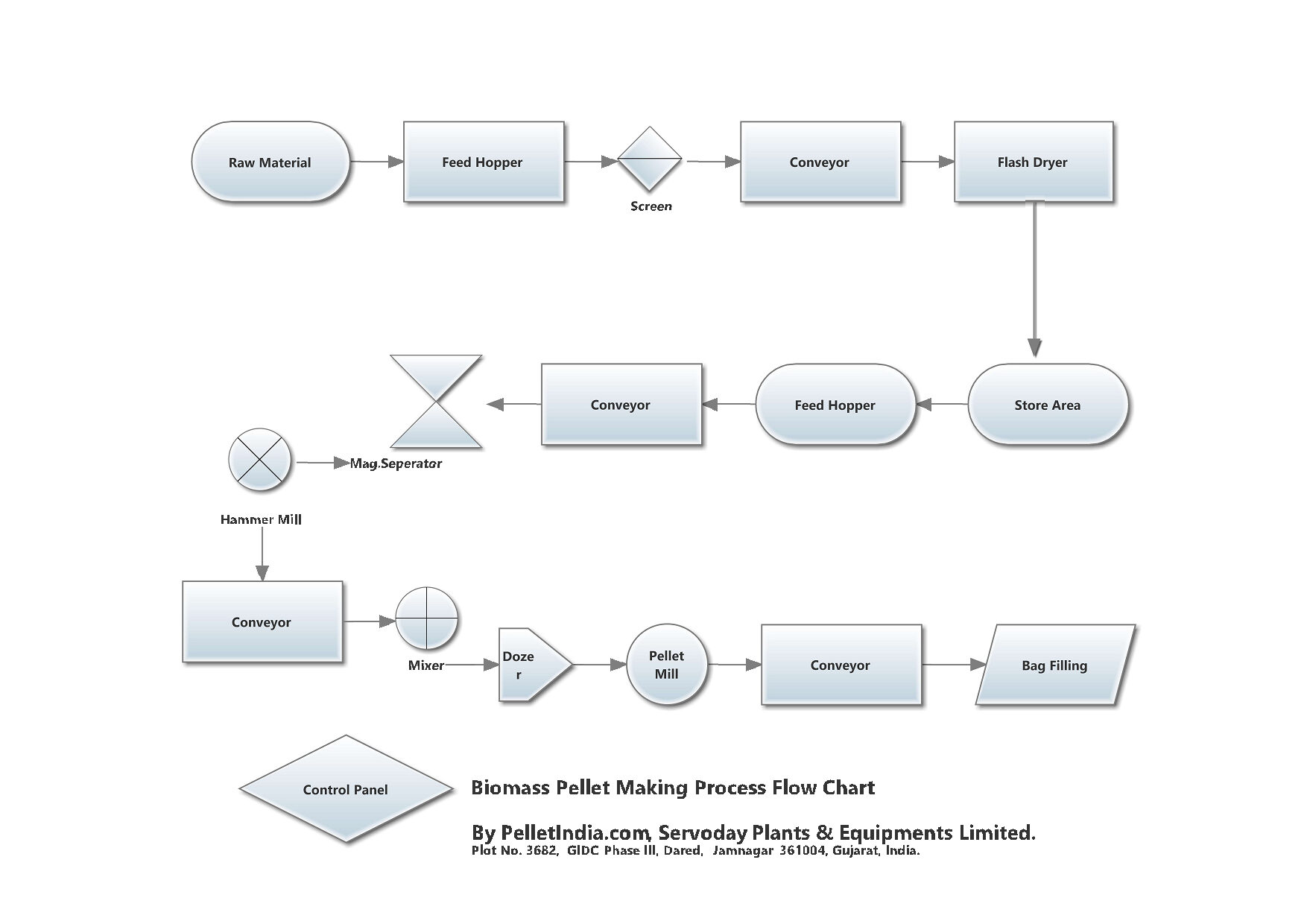

The Tower Biomass Pellet Plant arranges all the pellet production equipment in a vertically stacked configuration. This setup ensures that raw material handling, drying, pelletizing, and cooling are all conducted in a compact, gravity-driven manner. This unique vertical workflow allows for efficient material flow, reducing the need for extensive conveyor systems and other additional equipment typically used in horizontal designs.

Purpose

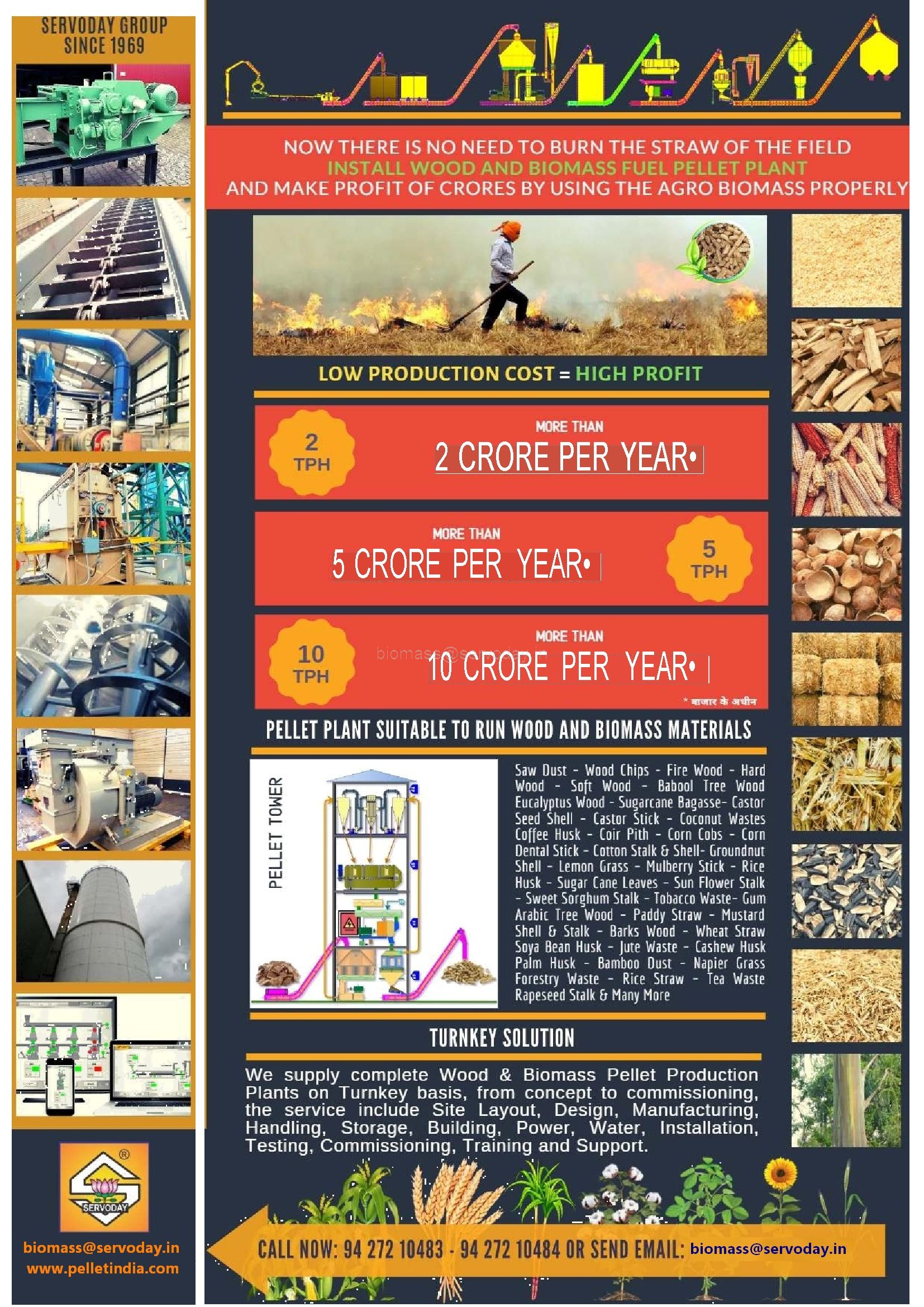

The main purpose of the Wood Biomass Tower Pellet Plant is to produce high-quality biomass pellets for use in power generation, heating, and industrial fuel applications. The plant is also designed to address the space limitations often faced in urban and industrial settings while still ensuring high-volume production of biomass pellets.

Significance

- Space Efficiency: The vertical arrangement of the equipment significantly reduces the land footprint required, making it a perfect solution for areas with limited available space.

- Sustainable Biomass Utilization: Contributes to renewable energy production by transforming a wide variety of biomass raw materials into pellets.

- Lower Operational Costs: By reducing the transport distances between processing stages through its vertical design, the plant enhances energy efficiency and cuts operational costs.

Key Features

- Vertical Workflow: Uses gravity to move materials through different stages, including drying, pelletizing, and cooling, minimizing mechanical handling and saving energy.

- Compact Design: Optimizes limited space, allowing high-capacity production within a smaller footprint compared to traditional horizontal biomass plants.

- Automated Control Systems: The plant can be equipped with automation for improved accuracy and reduced labor requirements, ensuring consistent production output.

- Energy Efficiency: Lower energy consumption due to the elimination of extensive conveyor systems, contributing to cost savings.

Unique Aspects

- Gravity-Driven Flow: Utilizes gravity for the movement of materials, reducing the number of mechanical systems needed and making the plant more energy-efficient.

- Ideal for Constrained Spaces: This design is specifically suited for urban environments or locations where land availability is a constraint, offering high production capacity despite limited space.

- Scalability: The plant can be configured to support production volumes of up to 1-2 tons per hour, ensuring flexibility in capacity based on operational needs.

Design Focus

- Space Optimization: The plant’s tower structure is designed to maximize output while minimizing land requirements, making it suitable for urban or high-value land areas.

- High Efficiency and Automation: Emphasis on reducing manual intervention through automation, while ensuring efficient energy use and low operational costs.

- Continuous Process Flow: The vertical design ensures that each stage flows seamlessly into the next, using gravity to facilitate material movement, which enhances overall system efficiency.

Raw Materials

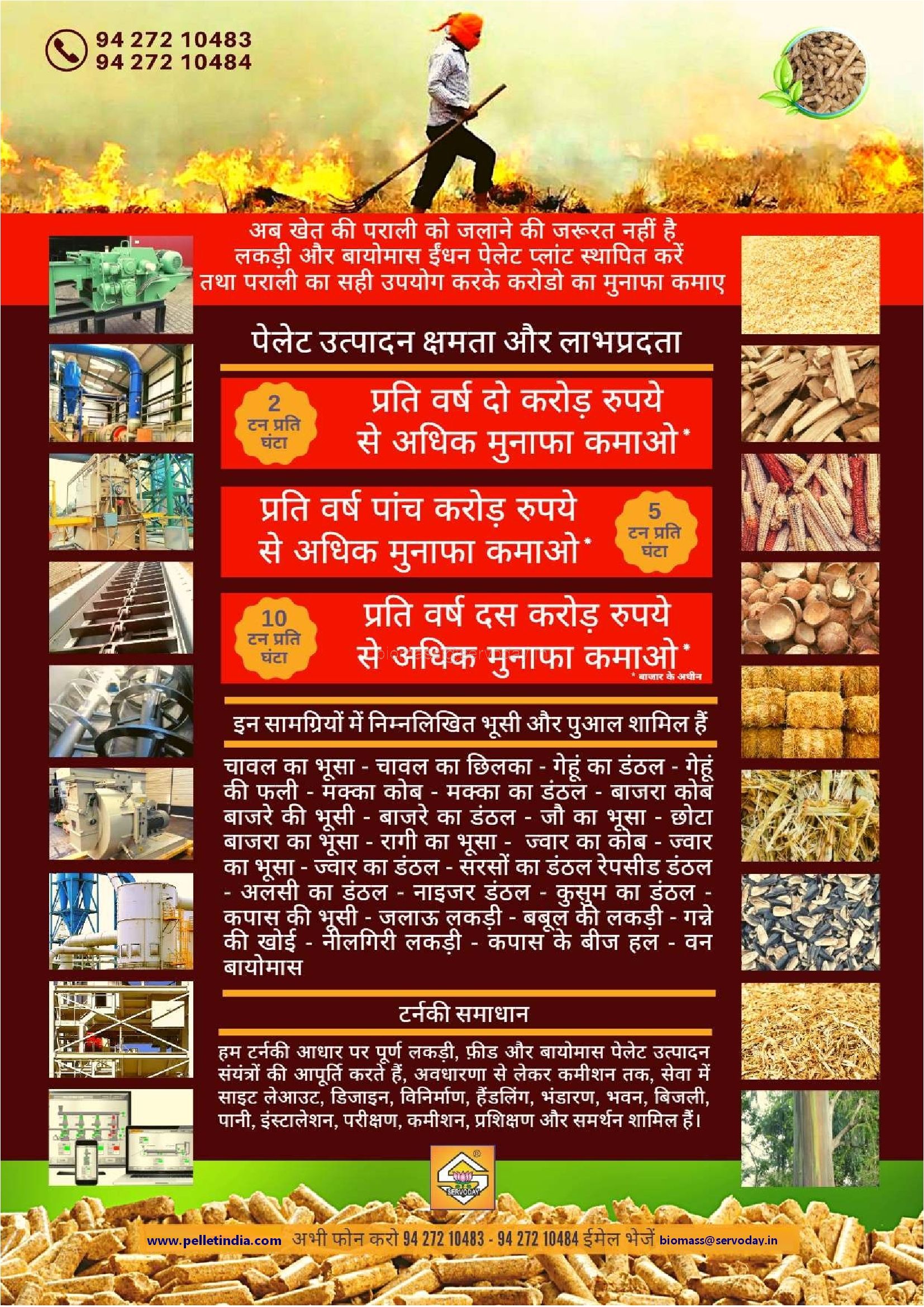

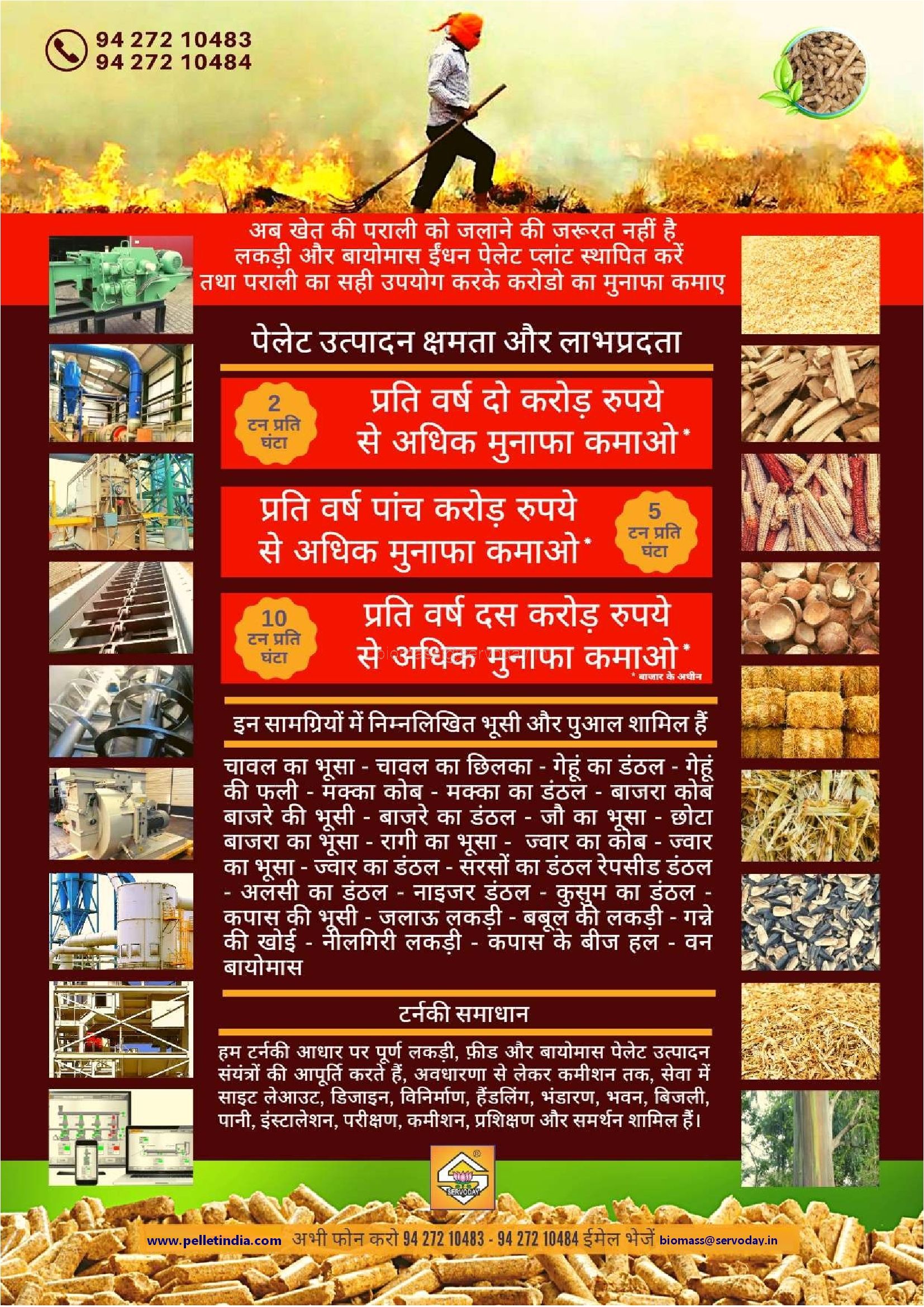

The Tower Biomass Plant can handle a wide variety of biomass materials, including:

- Agricultural Residues: Bagasse, castor seed shell, cotton stalk, groundnut shell, rice husk, wheat straw, paddy straw, and more.

- Wood Waste: Sawdust, wood chips, forestry waste, bamboo dust, barks wood.

- Other Biomass: Coconut wastes, coffee husk, sunflower stalk, mulberry sticks, jute waste, Napier grass, palm husk, tobacco waste, and agro residues.

Output Capacity

- Production Rate: Capable of producing between 1 and 2 tons of biomass pellets per hour, depending on the specific configuration and raw materials used.