Introduction

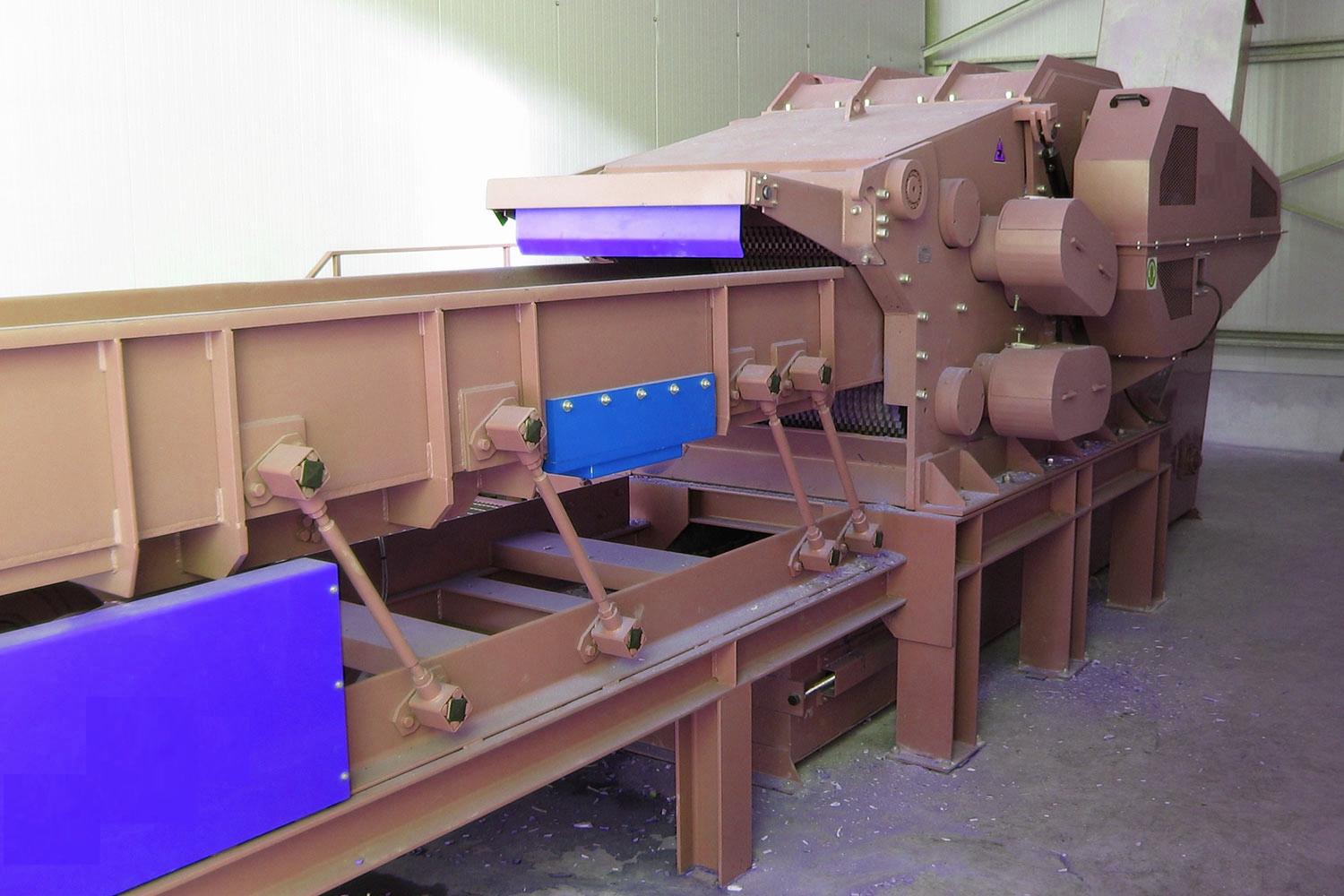

The Trommel Rotary Screen is a heavy-duty screening machine designed to separate different sizes of materials, primarily used in biomass and wood processing. It effectively removes oversized materials and foreign substances, ensuring high-quality biomass feedstock for downstream processing.

Overview

The Trommel Rotary Screen is designed for screening oversize materials from wood biomass and other bulk materials. The machine features a rotating drum with perforations of various sizes, allowing the separation of oversized and undersized fractions. With a capacity ranging from 1 to 10 tons per hour, it is suitable for diverse biomass operations, ensuring efficient screening and optimal material quality.

Purpose

The primary purpose of the Trommel Rotary Screen is to separate oversized materials from wood biomass and other bulk materials, ensuring that only properly sized particles proceed to subsequent processing stages. This screening process is vital for ensuring high-quality biomass pellet production and reducing operational issues in downstream equipment.

Significance

- Material Quality Control: Helps maintain the quality of biomass feedstock by efficiently separating oversized materials and contaminants.

- Versatile Screening: Capable of screening wood biomass, stones, and foreign materials, providing flexibility for different types of biomass processing needs.

- Enhanced Processing Efficiency: Ensures that only properly sized material is processed, reducing the likelihood of blockages and improving the efficiency of subsequent equipment, such as pellet mills.

Key Features

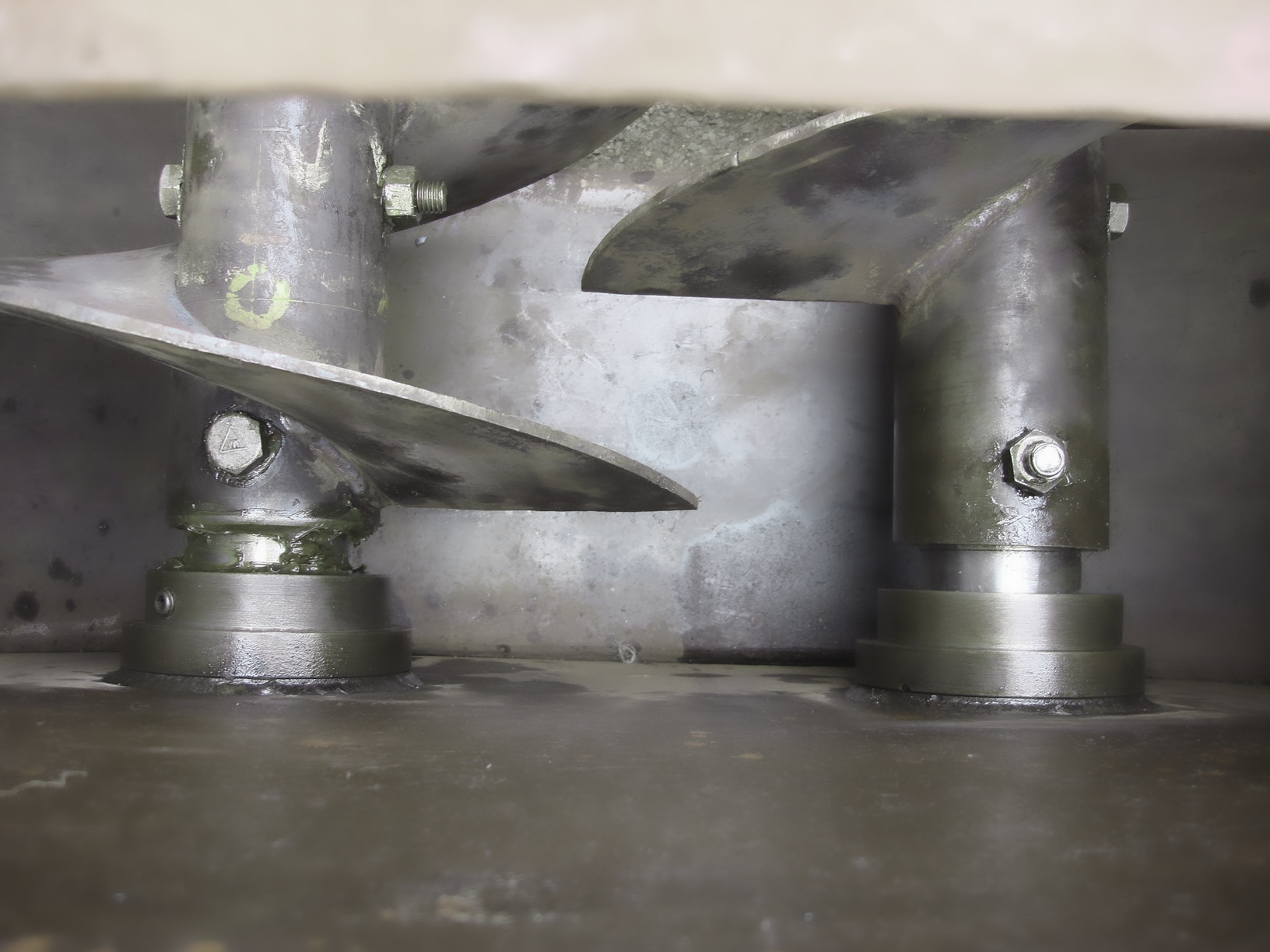

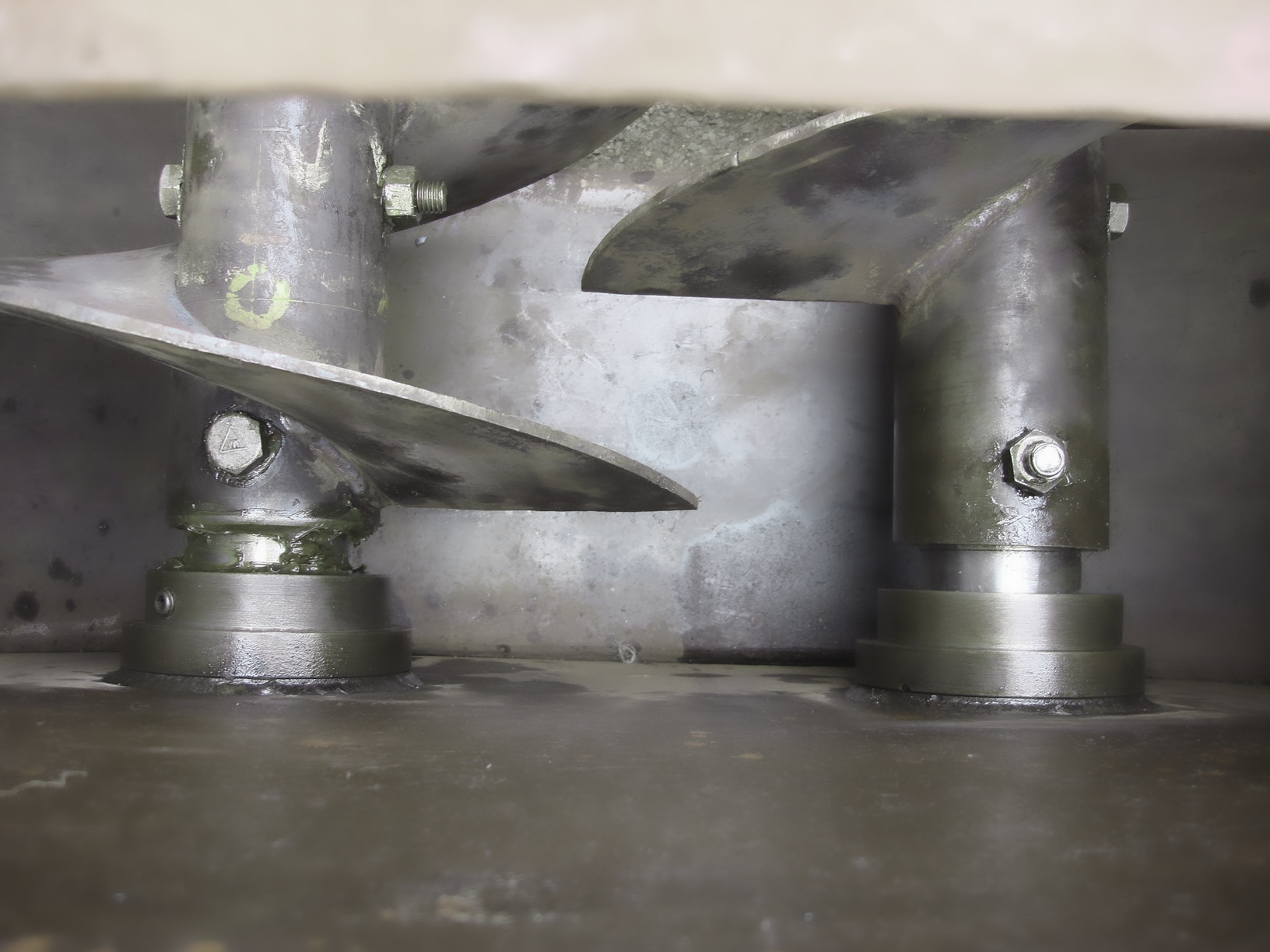

- Heavy-Duty Construction: Built with a robust main frame made from structural steel, providing stability and long-lasting performance under heavy load.

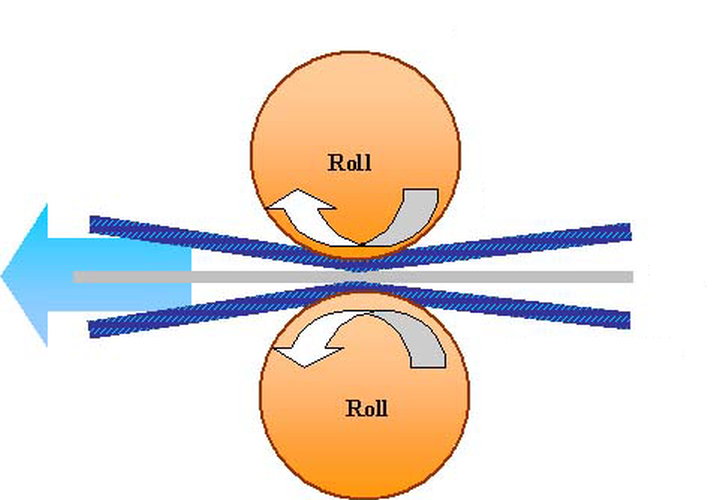

- Efficient Screening Process: The rotating screen drum allows for efficient separation, with undersized material falling through the perforations and oversized material being moved forward for manual handling.

- Loading Hopper and Discharge Mechanism: Equipped with a loading hopper for raw material and a discharge mechanism to transport finished material to a belt conveyor.

- Handling Capacity: Offers a capacity range from 1 TPH to 10 TPH, catering to small and large-scale biomass operations.

- Ease of Handling: Oversized materials are handled manually or mechanically, simplifying the process of separating unwanted components.

Unique Aspects

- Structural Stability: Additional sub-frame assemblies provide extra support, maintaining structural integrity and reliability during continuous operation.

- Smooth Material Flow: Designed to allow smooth material flow through the drum, minimizing blockages and improving overall throughput.

- Versatile Applications: Suitable for separating a variety of materials, including wood biomass, stones, and other foreign objects, making it adaptable to multiple types of biomass feedstocks.

Design Focus

- Robust Frame: Emphasis on heavy-duty structural steel to support the screen basket and drive mechanism, ensuring durability in demanding conditions.

- Efficient Screening Mechanism: Designed for maximum efficiency in separating different sizes of materials, which is crucial for biomass quality control.

- User-Friendly Operation: Features an easily accessible loading hopper and discharge system, ensuring ease of use and straightforward maintenance.

Raw Materials

The Trommel Rotary Screen is designed to screen various raw materials, including:

- Wood Biomass: Wood chips, sawdust, wood offcuts.

- Foreign Materials: Stones and other contaminants that need to be separated from the biomass.

Output Capacity

- Screening Capacity: Ranges from 1 to 10 tons per hour, depending on the type and size of the raw material.