Introduction

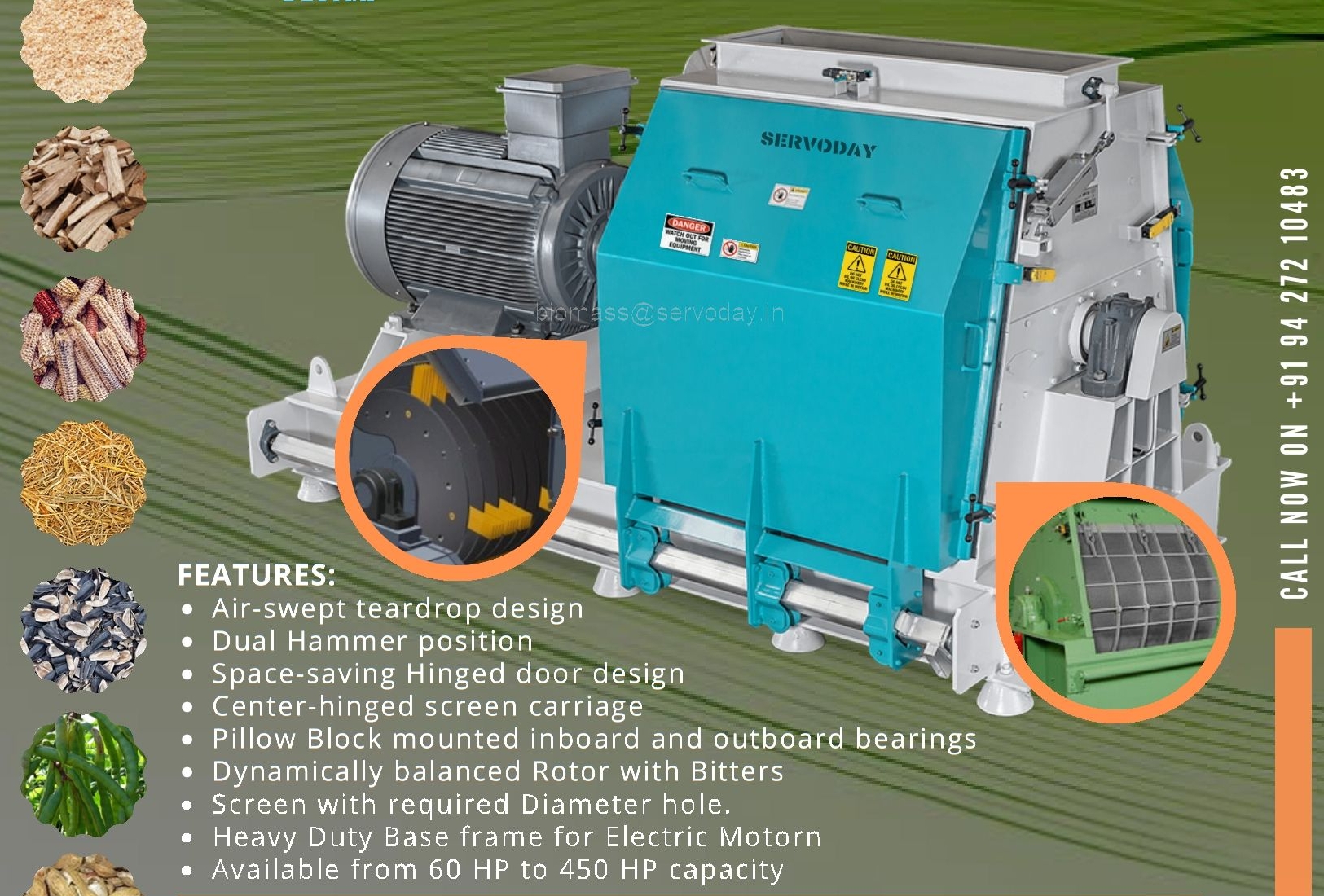

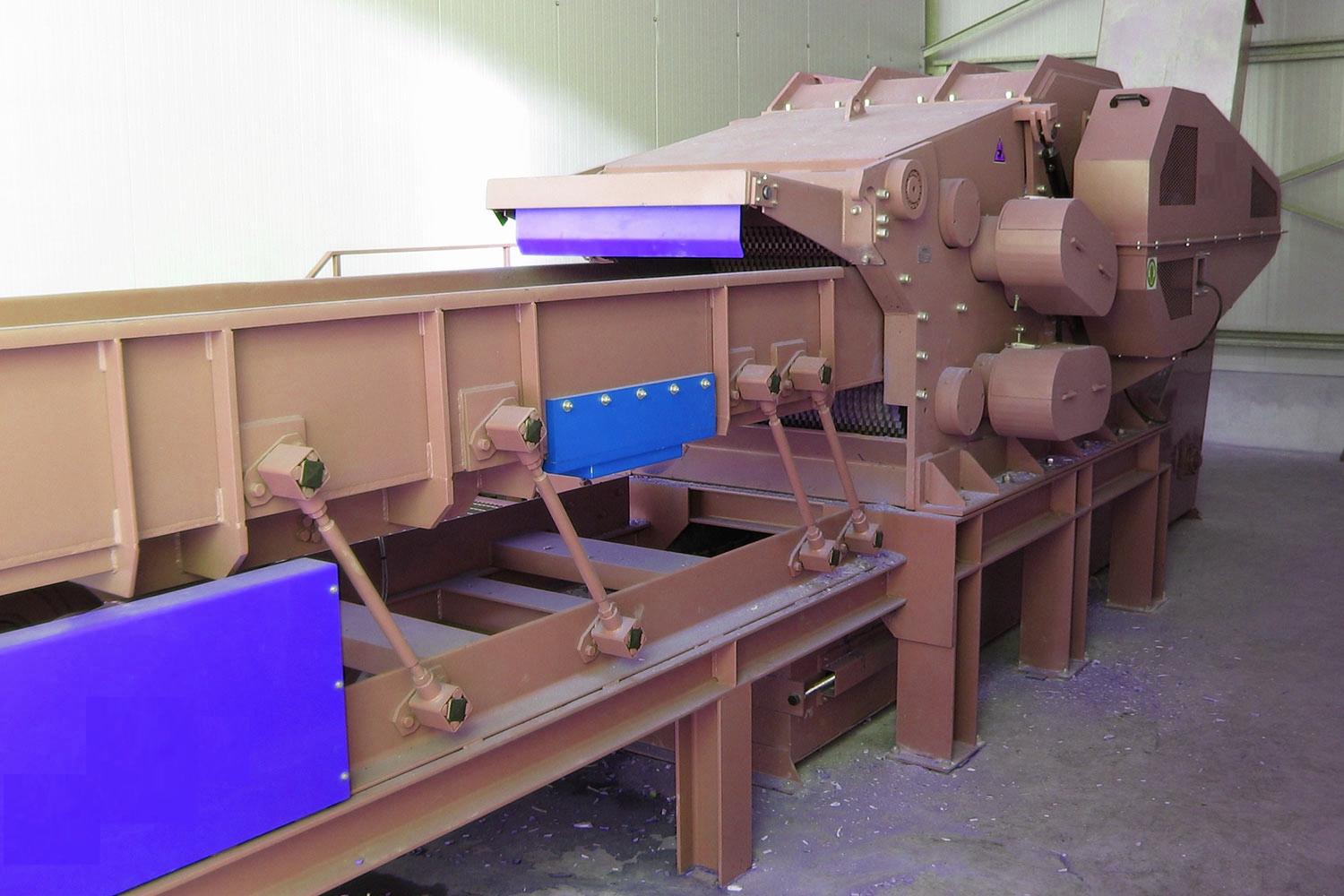

The Tear Drop Hammer Mill is a heavy-duty, high-performance grinding machine designed for applications such as biomass processing, feed production, and wood pellet plant operations. Its unique tear-drop-shaped chamber enhances the grinding efficiency, providing consistent results for a variety of materials. It is built for durability and efficiency, making it an ideal choice for demanding industrial applications.

Overview

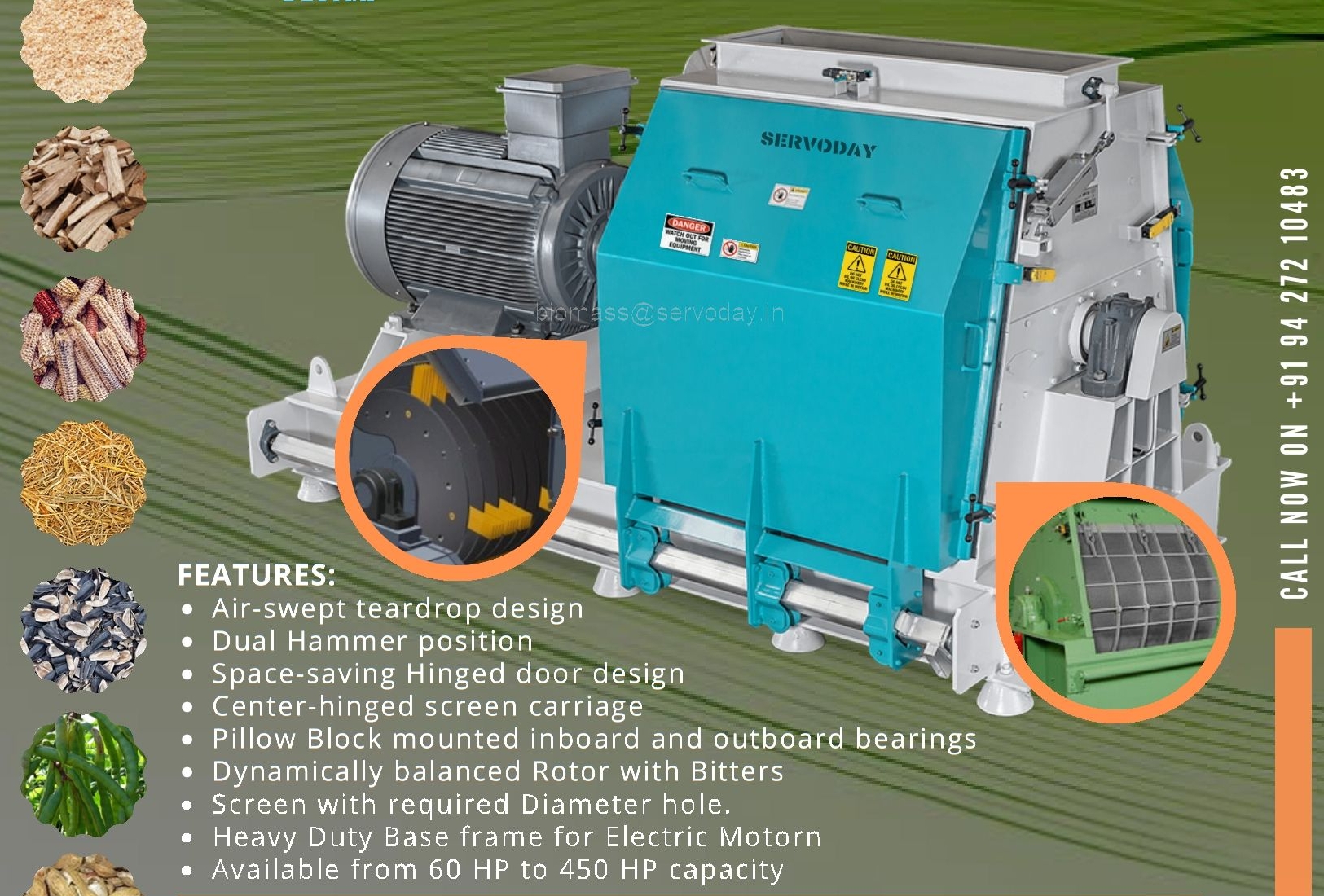

The Tear Drop Hammer Mill features a unique tear-drop-shaped grinding chamber that optimizes impact and shear forces, leading to effective size reduction. It is designed with a heavy-duty frame to minimize vibration and noise during operation. The mill is suitable for both small-scale and large-scale operations, offering models of different sizes to meet diverse requirements.

Purpose

The primary purpose of the Tear Drop Hammer Mill is to reduce the particle size of materials such as biomass, wood, grains, and other bulk solids. This makes it an essential component in biomass processing plants, feed milling, and wood pellet production. The consistent size reduction achieved by the mill is crucial for ensuring the quality of the final products in these applications.

Significance

- High Efficiency Grinding: The tear-drop design maximizes impact force on the material, enhancing the efficiency of the size reduction process.

- Versatility: The mill is suitable for a wide range of applications, including biomass, wood, and feed production, making it a versatile addition to many industrial operations.

- Space Optimization: Its compact design makes it suitable for installations with limited space while still maintaining high throughput.

Key Features

- Dual Hammer Positioning: Allows for optimal hammer utilization, enhancing the grinding efficiency and increasing the lifespan of the hammers.

- Tear Drop Design Chamber: Increases the effective grinding area, resulting in higher grinding capacity and efficiency.

- Robust Construction: Built with a heavy-duty frame that minimizes vibration and noise, ensuring stable and reliable performance.

- Easy Maintenance Access: Full-access pivoting doors provide easy access for maintenance and servicing, reducing downtime.

- Advanced Safety Features: Equipped with bearing temperature probes, vibration switches, and trap key interlocks to ensure safe operation.

Unique Aspects

- Regrind Chamber: The unique regrind chamber design allows for additional material processing, ensuring finer and more uniform particle sizes.

- Diamond Hammers: The use of diamond-shaped hammers provides a longer service life, reducing the frequency of replacement and maintenance costs.

- Adaptability: Capable of processing various feedstock types, including grains, forages, biomass, and other fibrous materials, making it suitable for diverse applications.

Design Focus

- High Throughput: Designed to achieve high throughput with a capacity of up to 10 tons per hour, making it suitable for large-scale processing operations.

- Energy Efficiency: The efficient grinding chamber design helps reduce energy consumption per unit of material processed, providing economic benefits to operators.

- Durability and Low Maintenance: Constructed with abrasion-resistant wear liners and equipped with advanced safety features to reduce wear and maintenance needs.

Raw Materials

The Tear Drop Hammer Mill can process a wide variety of materials, including:

- Agricultural Residues: Rice husk, wheat straw, paddy straw, corn cobs, sunflower stalks, cotton stalks.

- Wood Waste: Sawdust, wood chips, bamboo dust, forestry waste.

- Other Biomass: Bagasse, coir pith, coffee husk, jute waste, Napier grass, coconut shells, fibrous plant materials.

Output Capacity

- Production Rate: The mill has a capacity of up to 10 tons per hour, depending on the type of material being processed and the specific mill model used.