Introduction

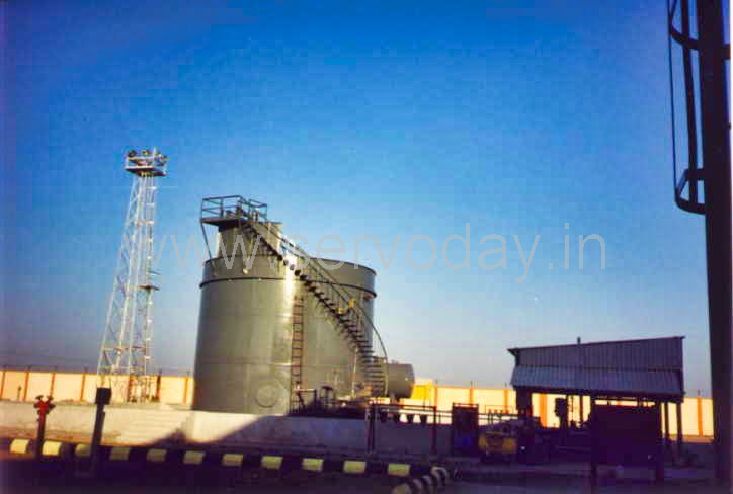

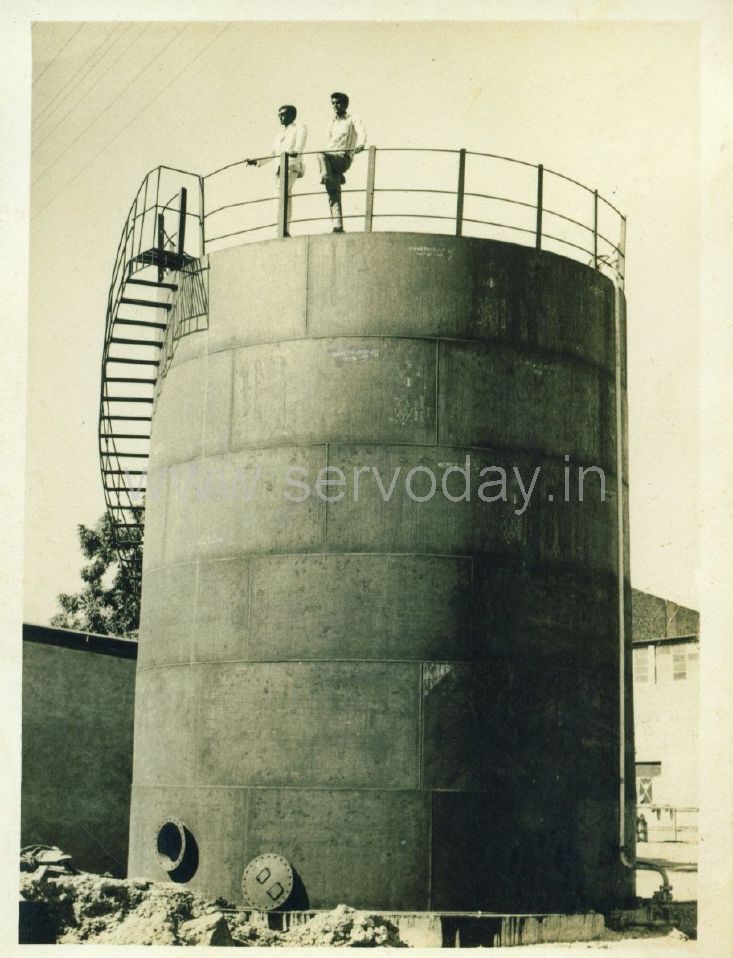

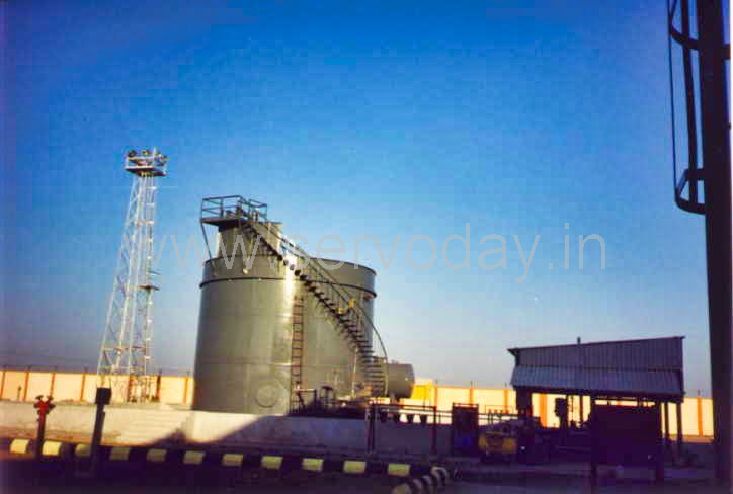

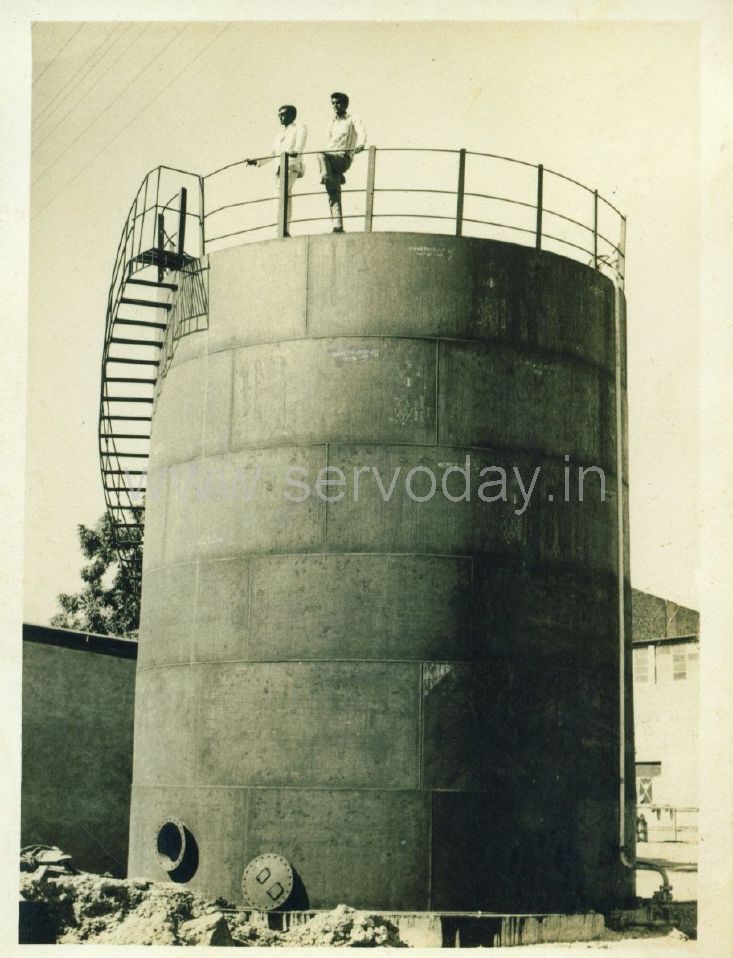

Storage Tank Farm & Distribution Systems by Servoday are engineered to meet diverse storage needs for bulk liquids across various industries. Designed according to API standards, these tanks offer reliable and efficient storage solutions for materials such as water, chemicals, and petroleum products.

Overview

Servoday provides a variety of storage tanks including cone roof, floating roof, low-temperature, horizontal pressure tanks, and more. These tanks cater to different applications, ensuring safety and efficiency for bulk liquid storage. The tanks comply with API standards (API 650, API 653, API 2000, API RP 545) for quality and safety assurance.

Purpose

The primary purpose of these storage tanks is to store bulk liquids, ranging from chemicals to petroleum products, in a safe and efficient manner. They are designed to address specific storage needs, including minimizing vapor loss, accommodating temperature-sensitive liquids, and storing pressurized gases.

Significance

Storage Tank Farm & Distribution Systems play a crucial role in maintaining operational efficiency across various industries, including oil and gas, chemicals, and agriculture. Their adherence to API standards ensures durability, safety, and efficiency, making them suitable for a range of industrial applications.

Key Features

- Wide range of tank types: Cone Roof, Floating Roof, Low-Temperature, Horizontal Pressure Tanks, Horton Sphere Pressure Tanks, and more

- Available for storing different types of liquids such as water, chemicals, petroleum products, cryogenic liquids, and more

- Designed according to API standards for safety and efficiency

- Different configurations including above-ground, underground, horizontal, and vertical tanks

- Options for double-walled tanks for enhanced leak protection

Unique Aspects

The diverse range of tank types available ensures that the specific needs of each industry are met, from minimizing vapor loss in volatile liquids to providing safe storage for cryogenic or pressurized substances. Additionally, double-walled tanks provide added safety for hazardous liquids.

Design Focus

The design of the Storage Tank Farm & Distribution Systems emphasizes safety, durability, and adaptability. The tanks are constructed using high-quality materials like mild steel and stainless steel to suit different storage requirements. API compliance ensures the highest standards in tank design, focusing on minimizing risks associated with handling bulk liquids.

Raw Materials

- Material of Construction: Stainless Steel (SS), Mild Steel (MS) depending on the liquid type, durability needs, and regulatory requirements

- Additional materials and coatings for corrosion resistance in chemical storage applications

Output Capacity

- Tanks available in a variety of configurations and capacities to meet specific storage requirements for bulk liquids

- Suitable for both small-scale and large-scale storage applications across various industries