Introduction

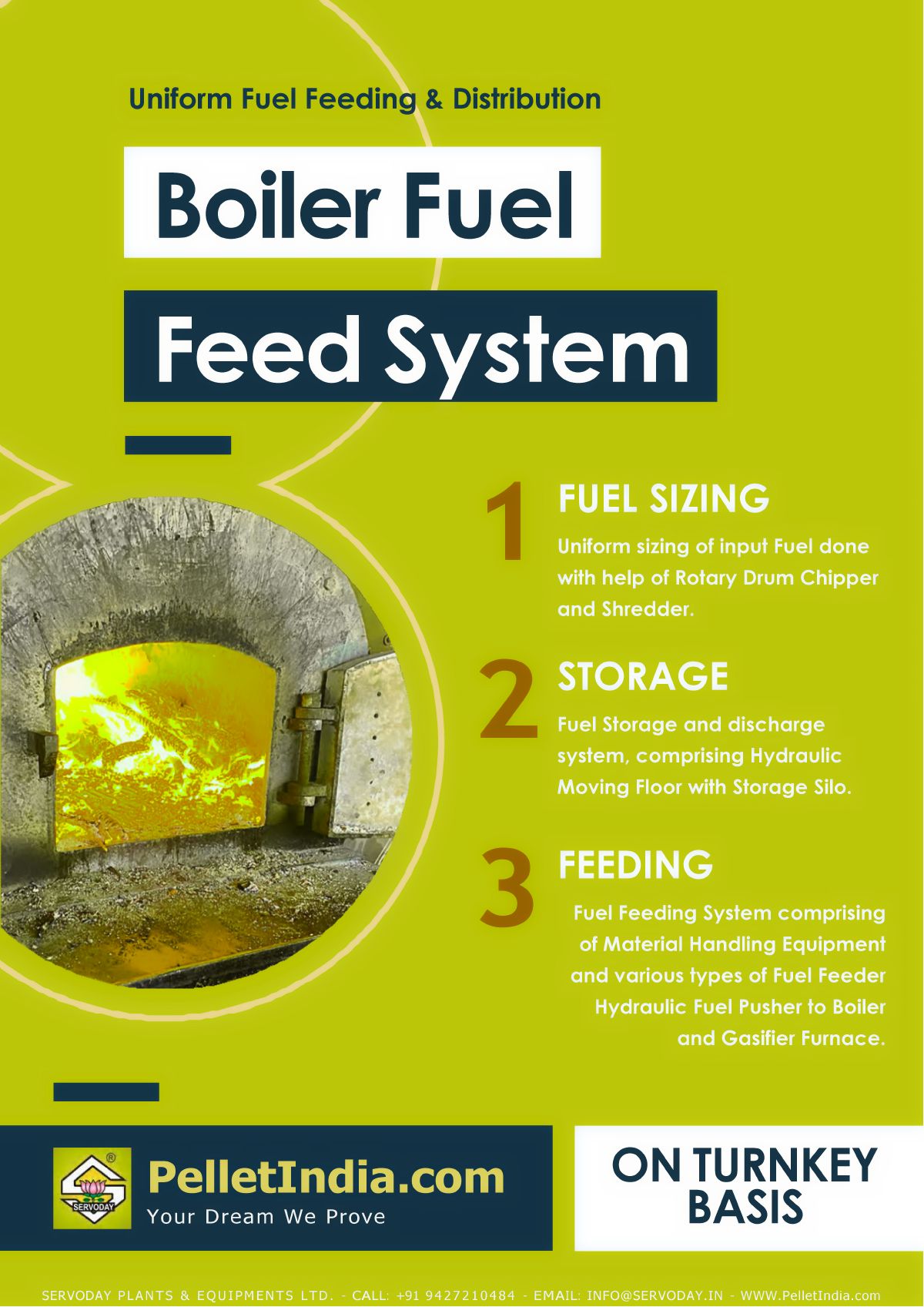

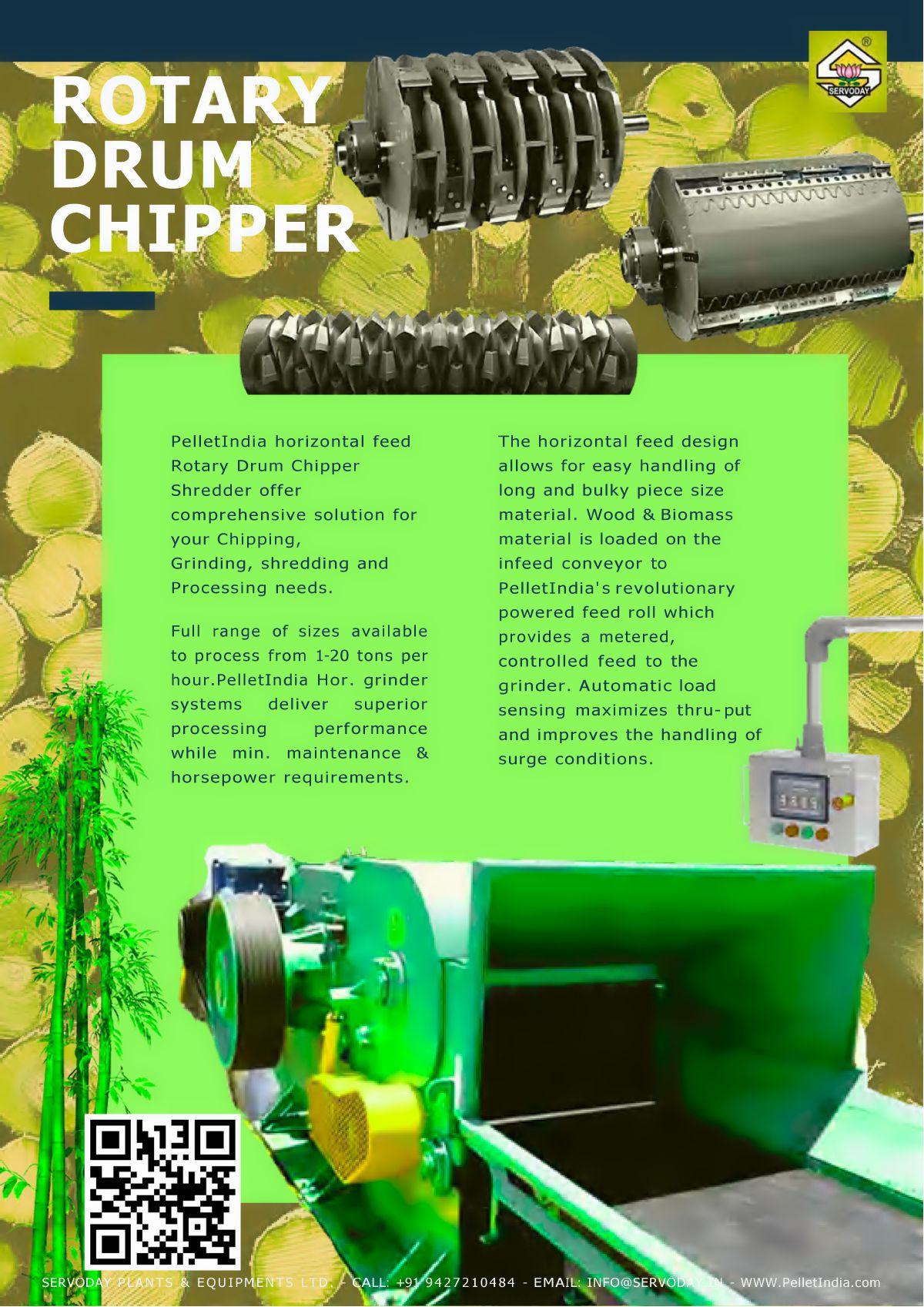

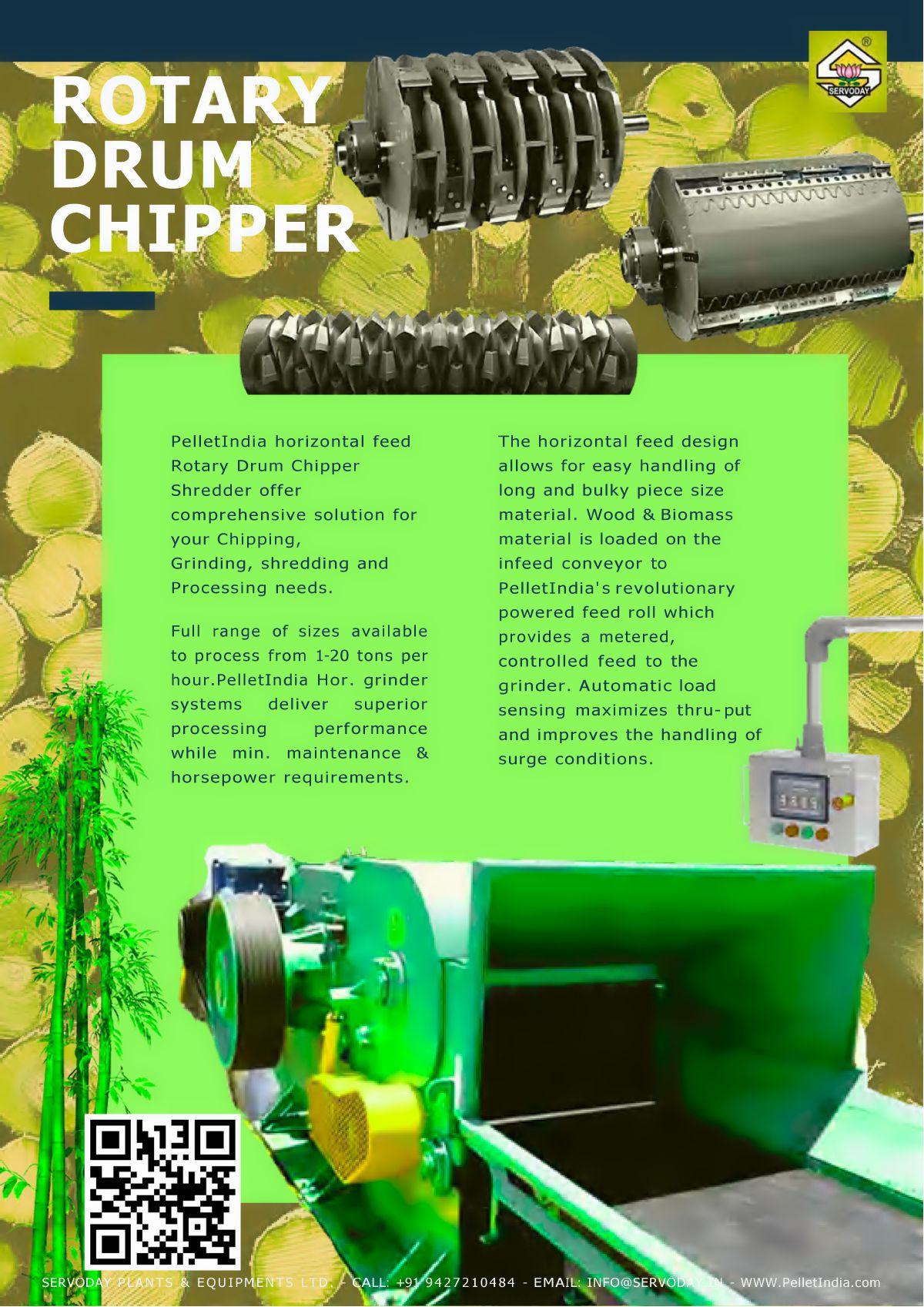

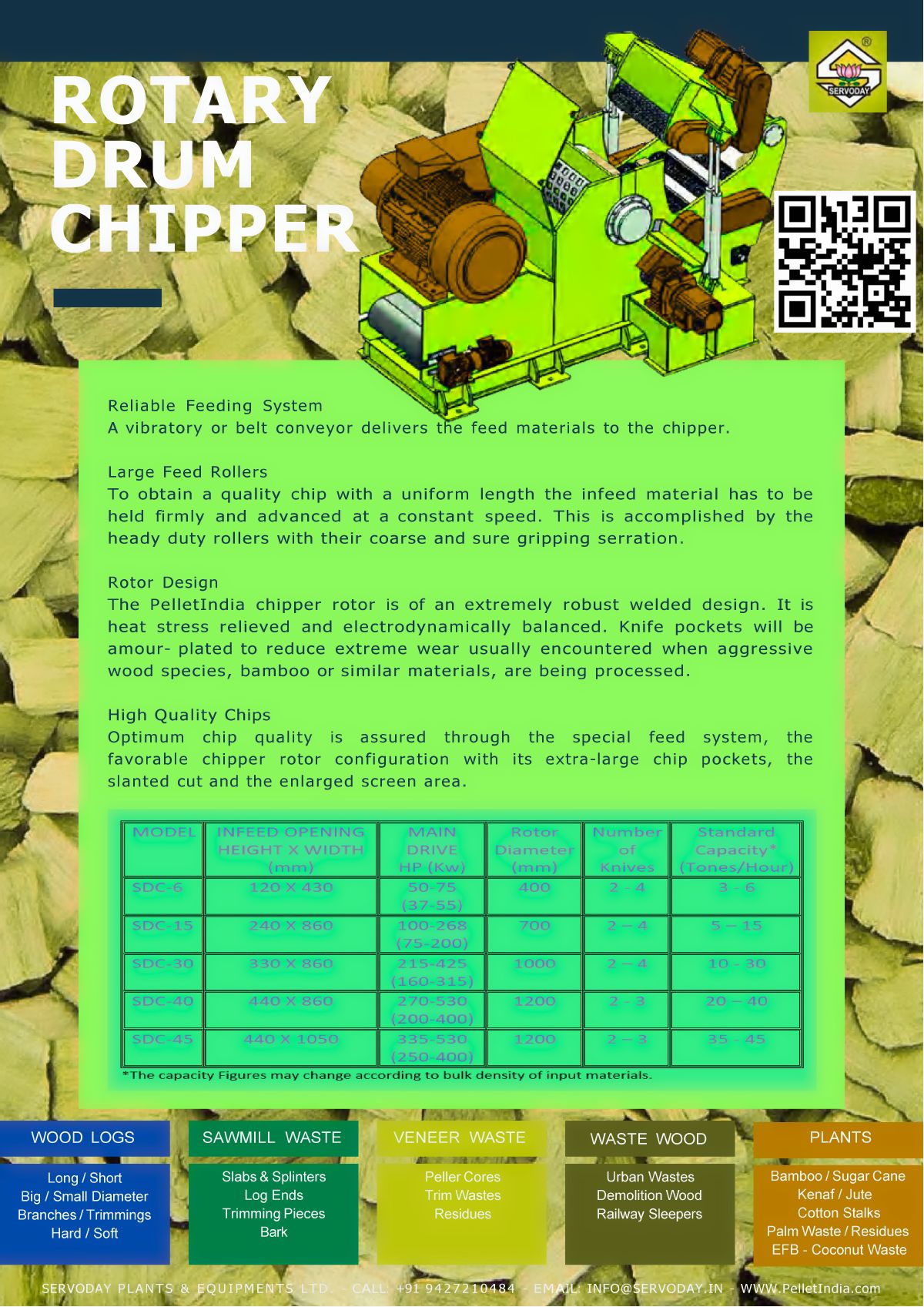

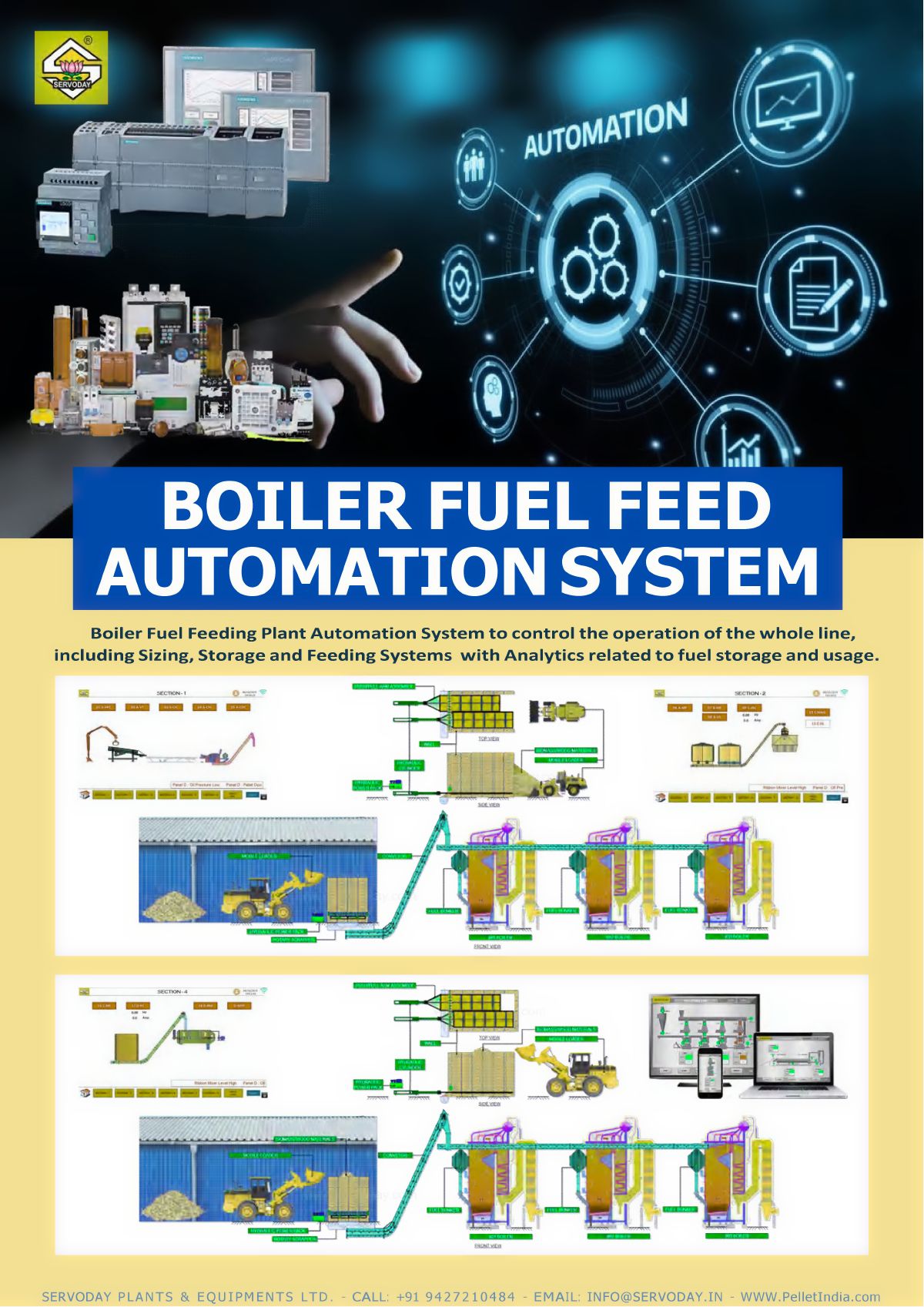

The Boiler Biomass Feed System is an advanced solution designed to efficiently deliver biomass materials to boilers for combustion. Developed by PelletIndia, this system is suitable for both small and large-scale biomass operations, offering precision, reliability, and high capacity. The feed system integrates automation and advanced metering technologies to ensure optimized fuel supply for continuous and effective boiler operation.

Overview

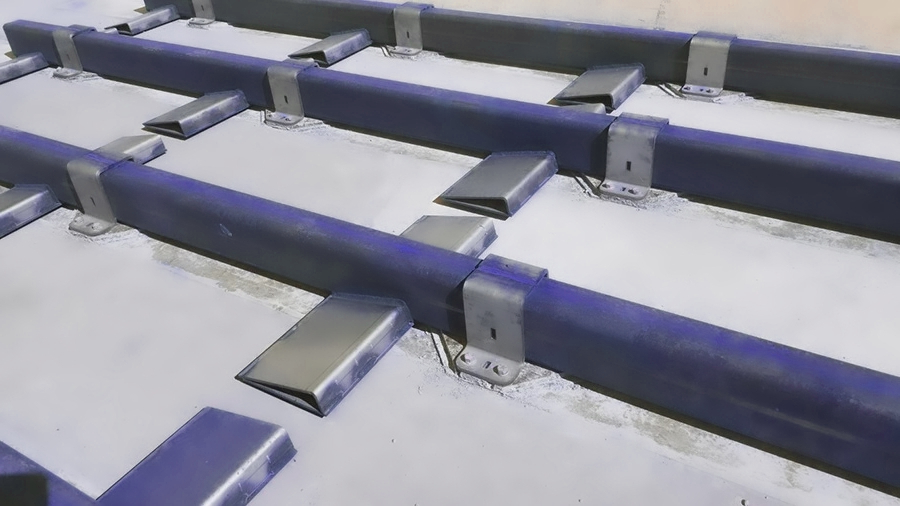

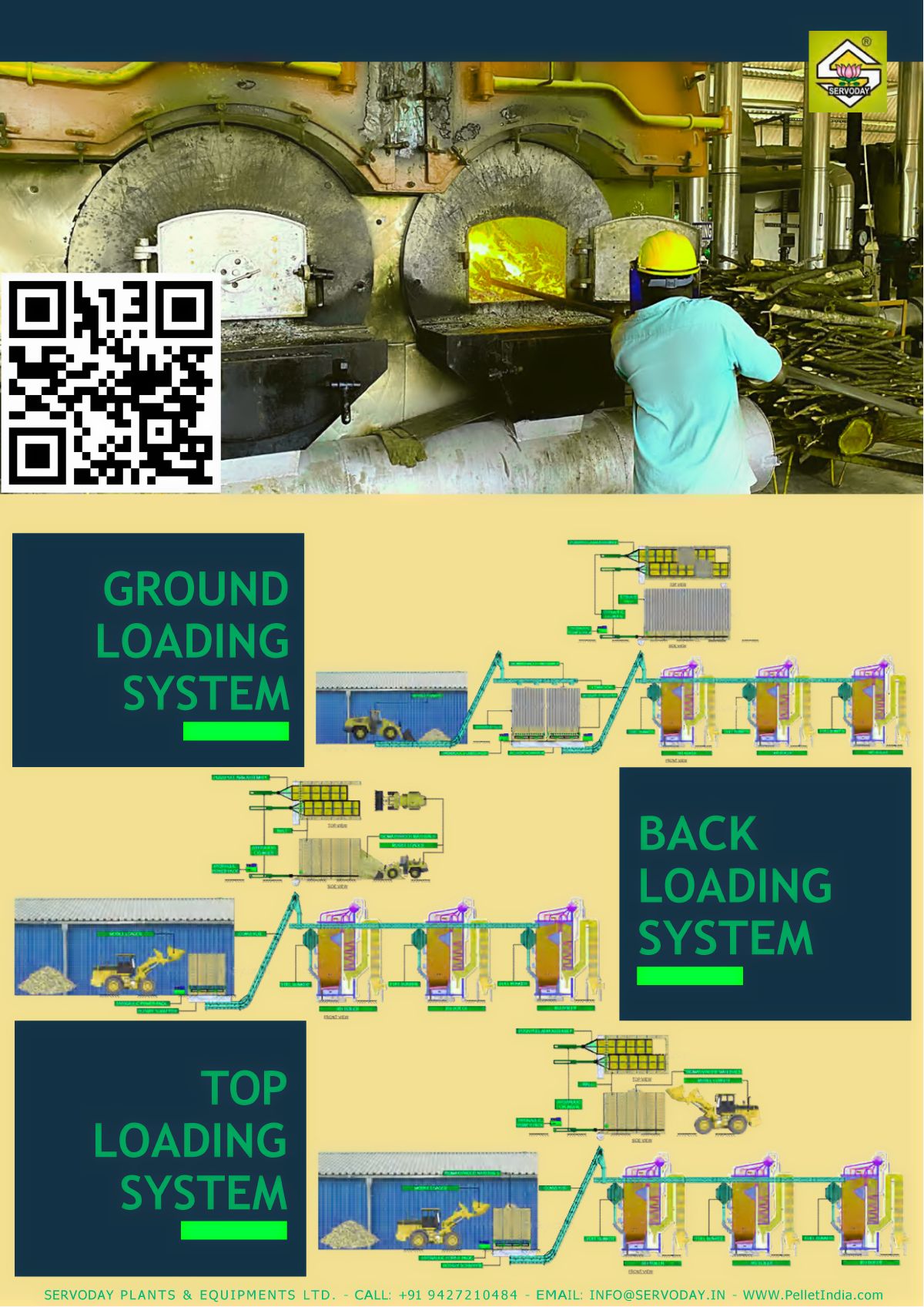

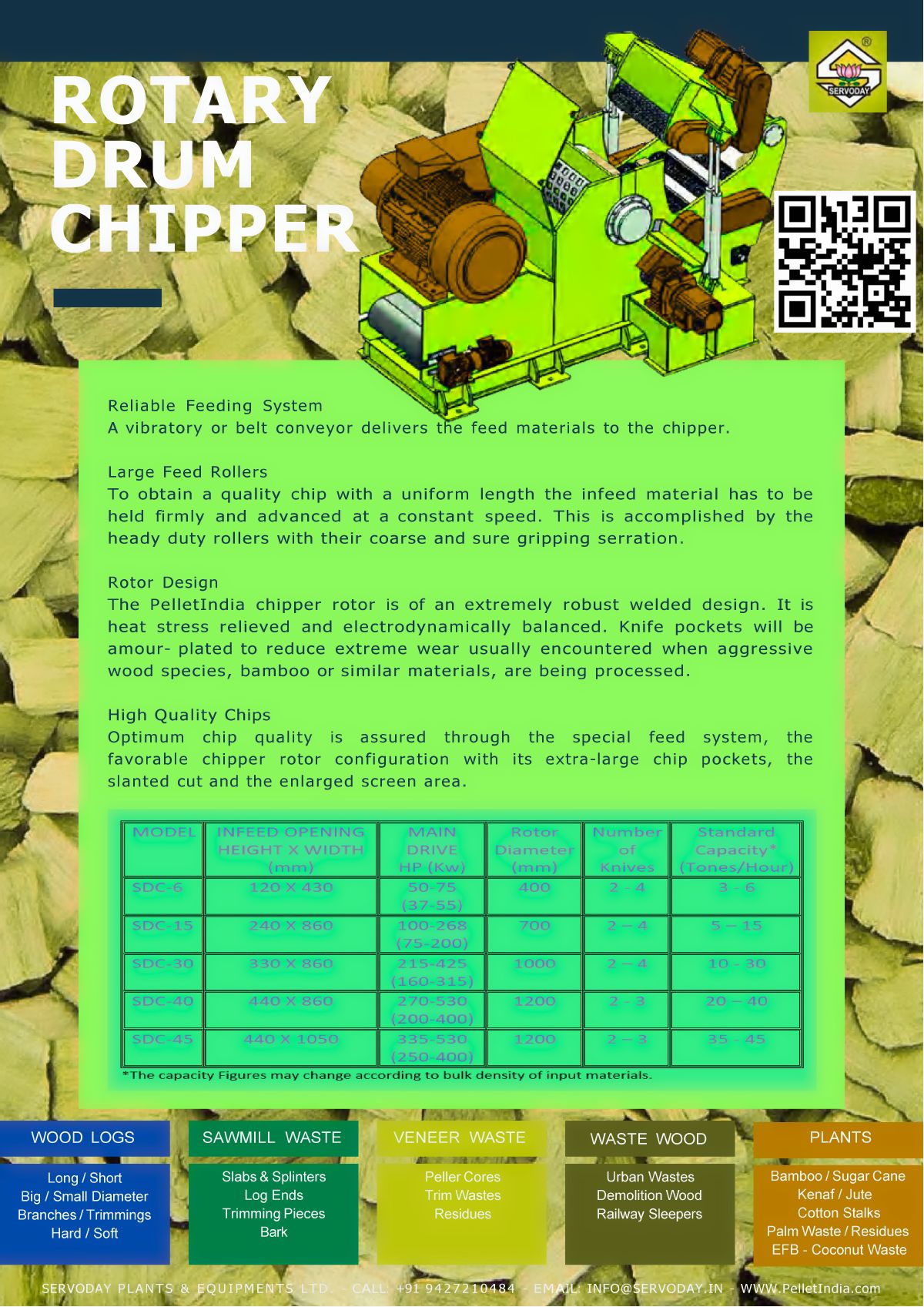

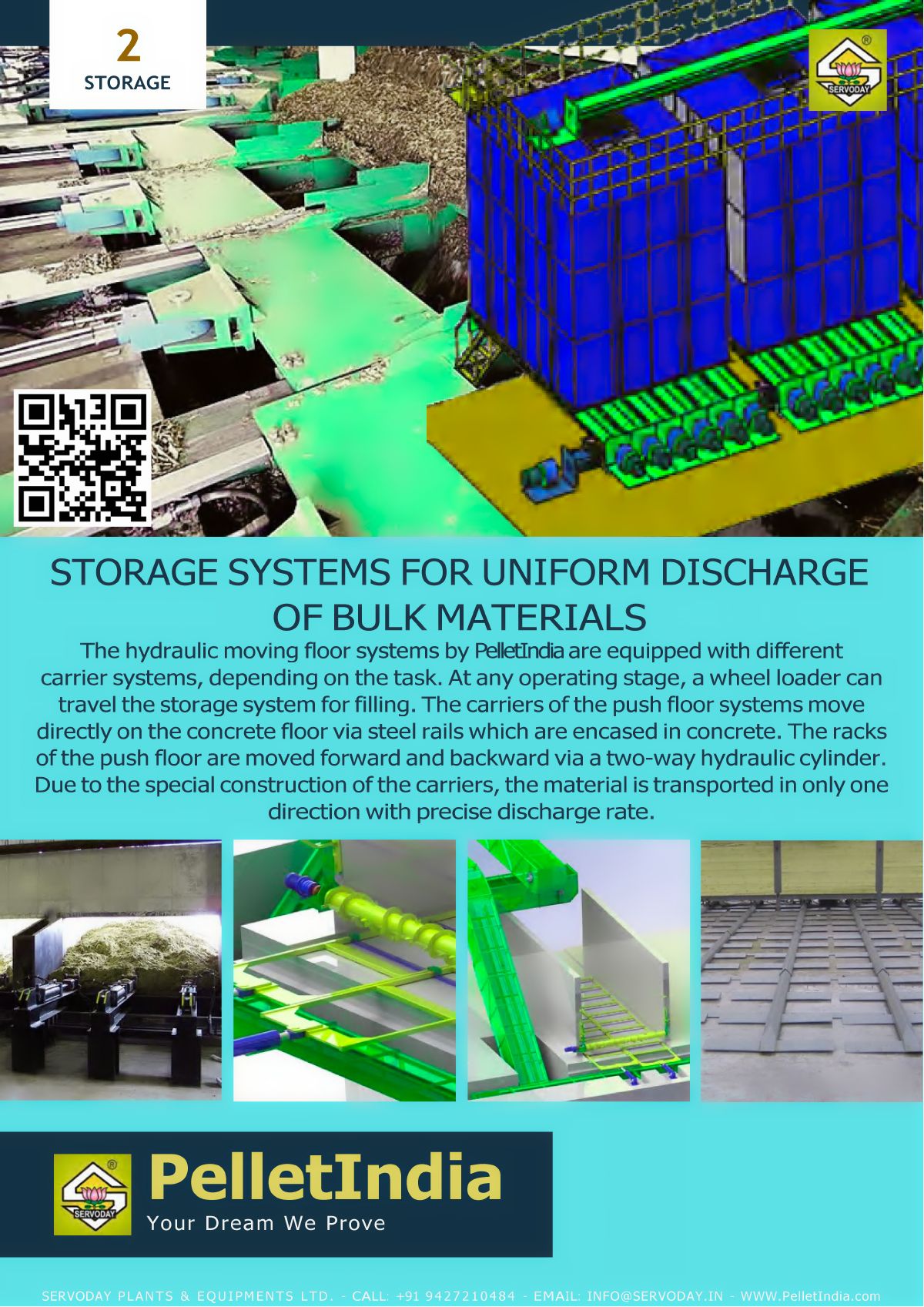

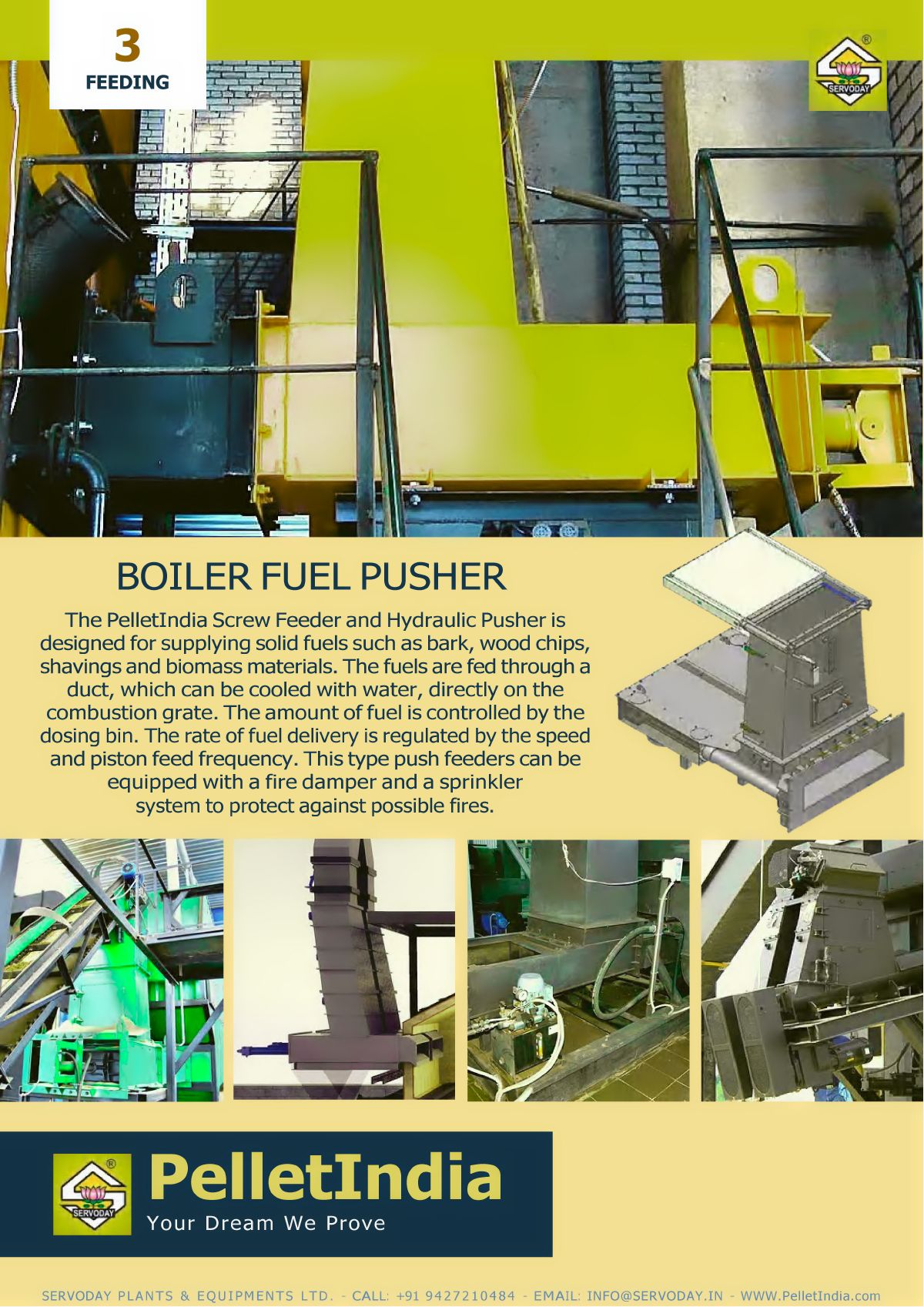

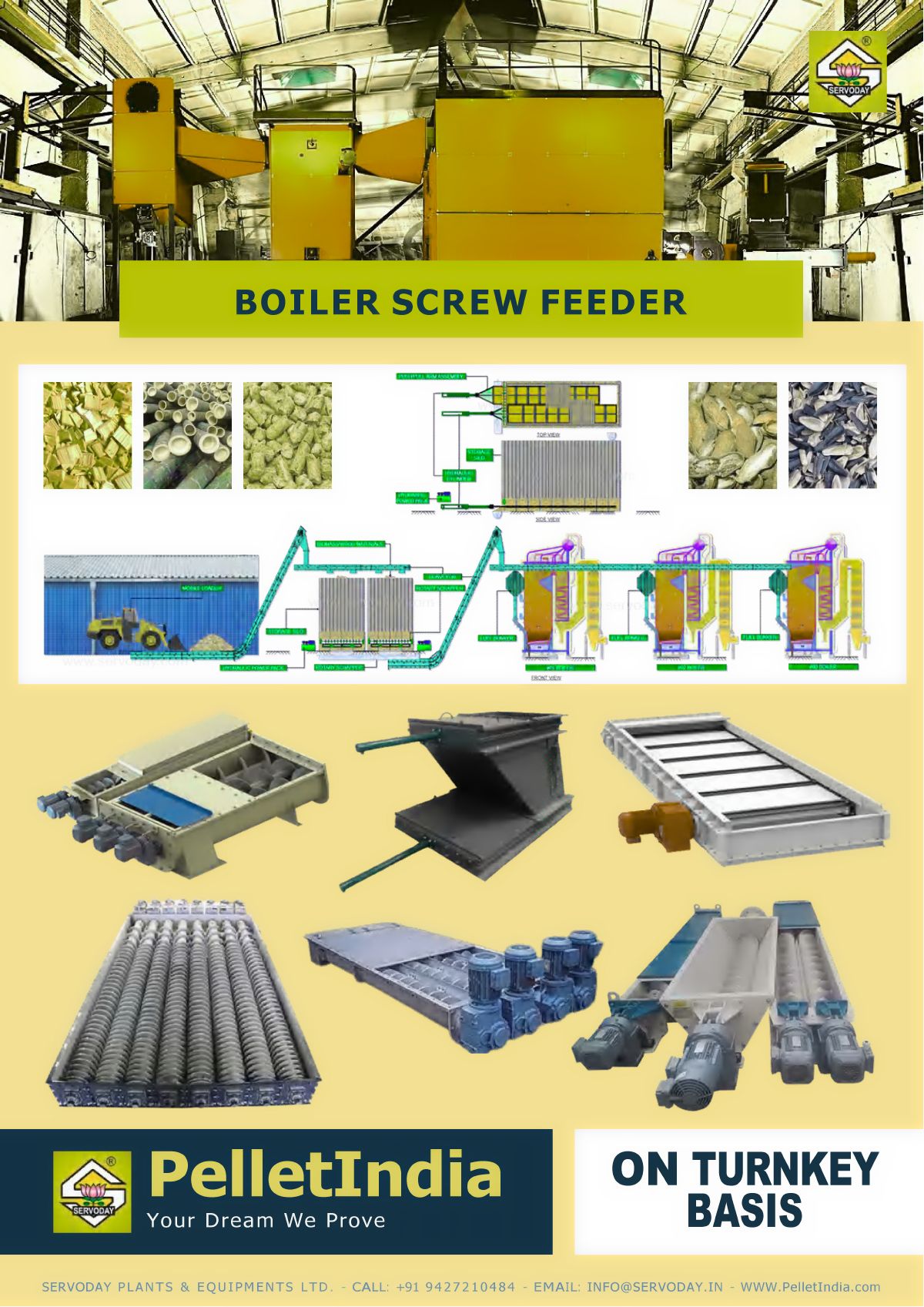

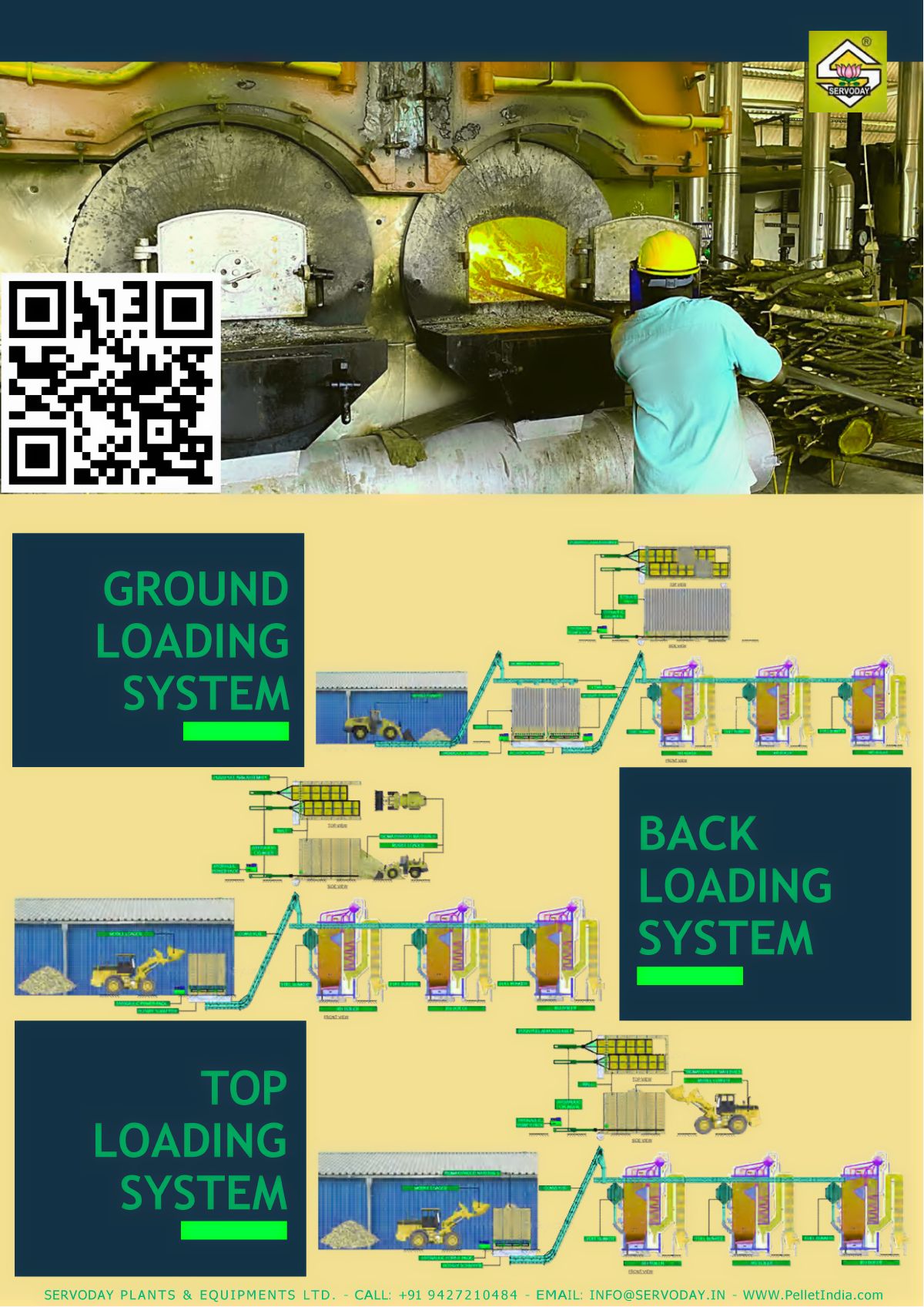

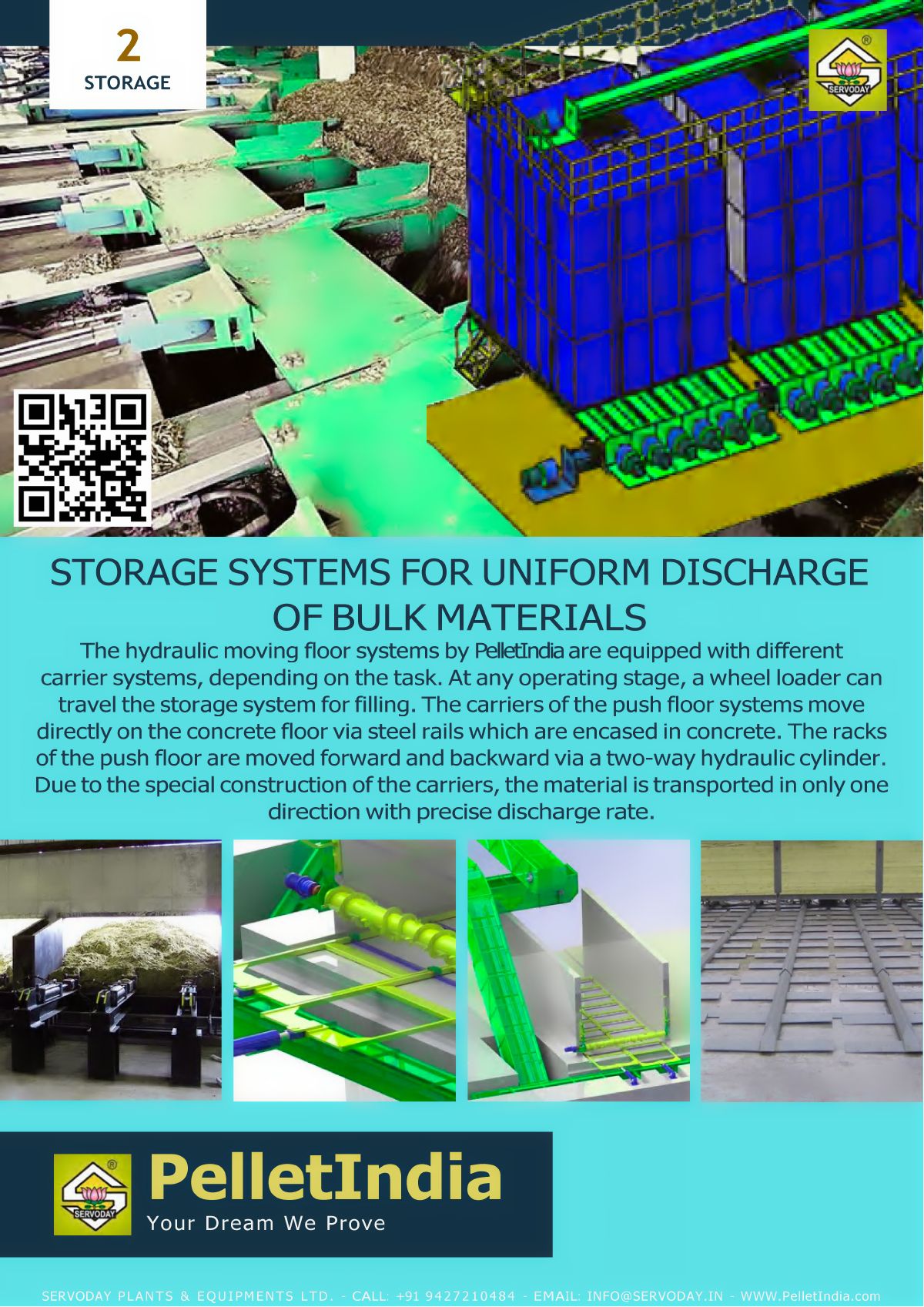

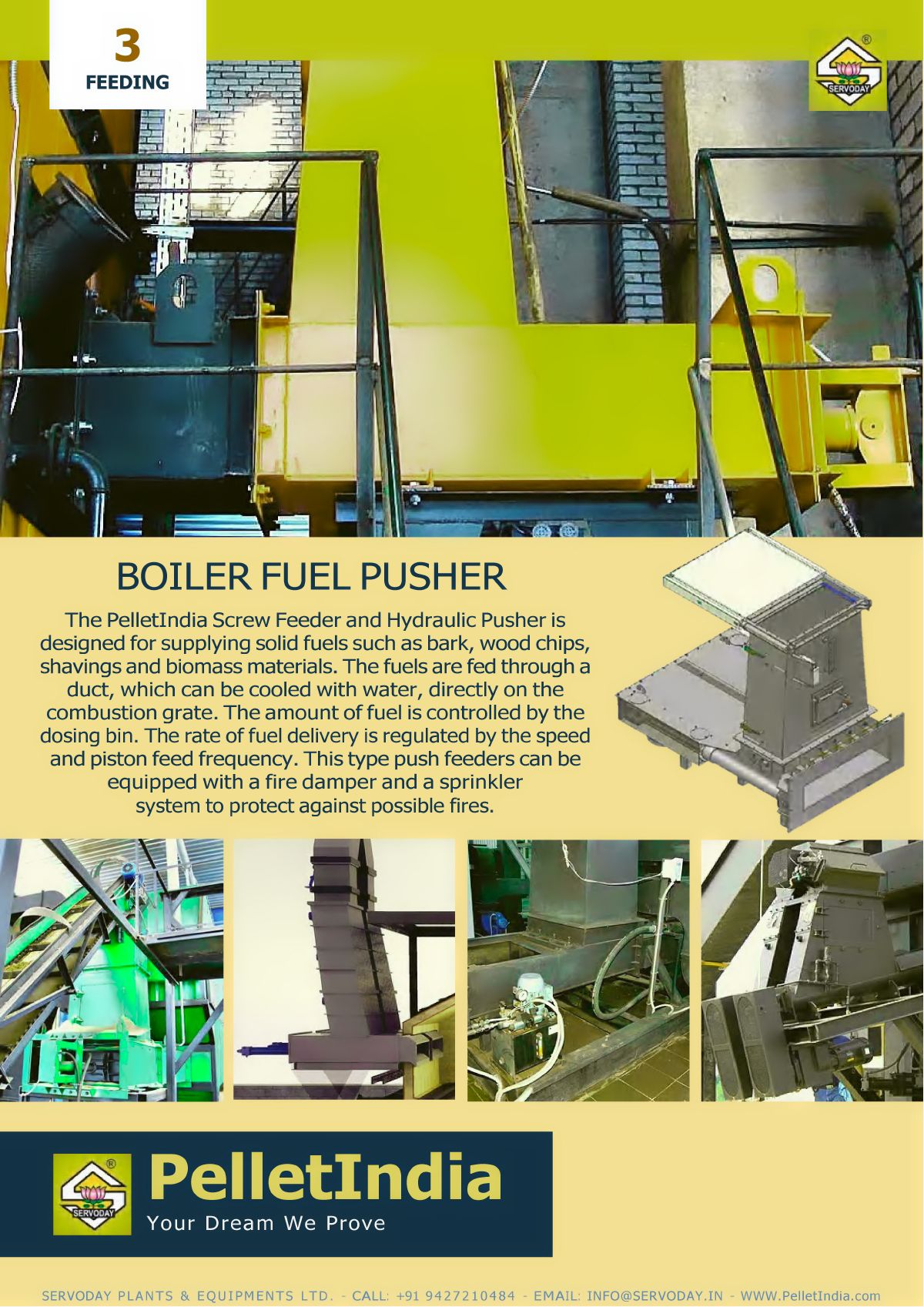

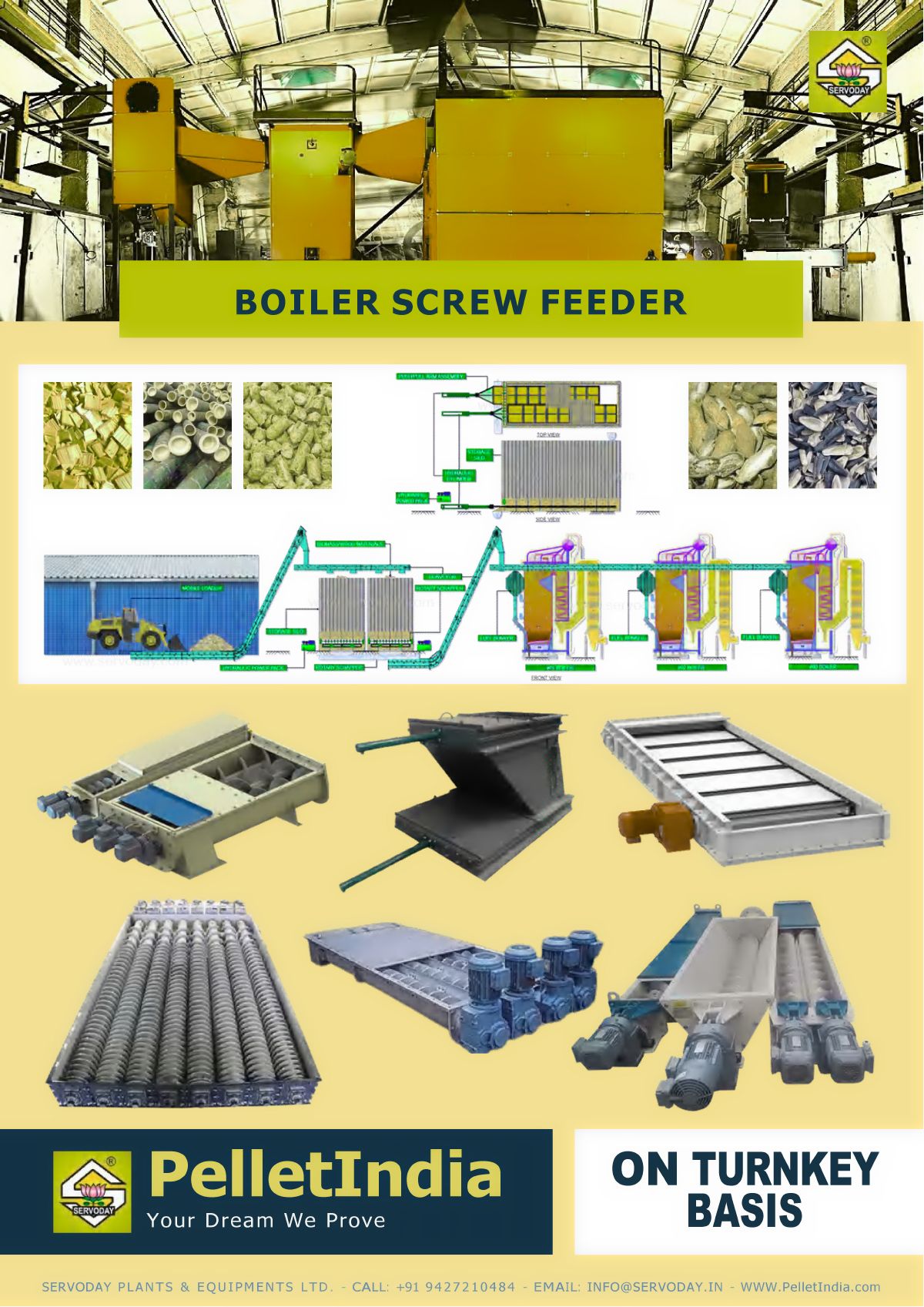

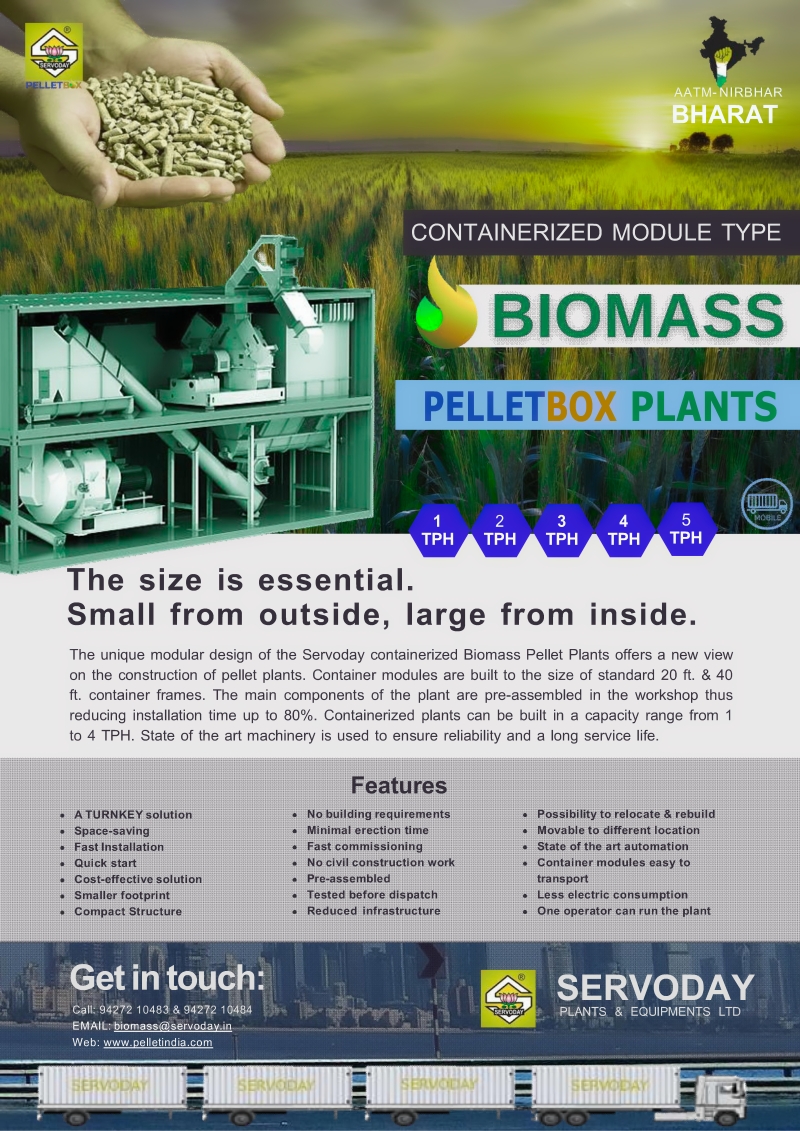

The Boiler Biomass Feed System by PelletIndia offers a complete fuel feeding solution for biomass boilers, designed to handle a variety of biomass materials. It is built to ensure a steady and controlled supply of biomass to the boiler, enabling efficient and optimized combustion. The system incorporates components such as day bins, silos, metering screws, rotary airlock feeders, and pneumatic injection systems, making it a comprehensive solution for biomass fuel handling.

Purpose

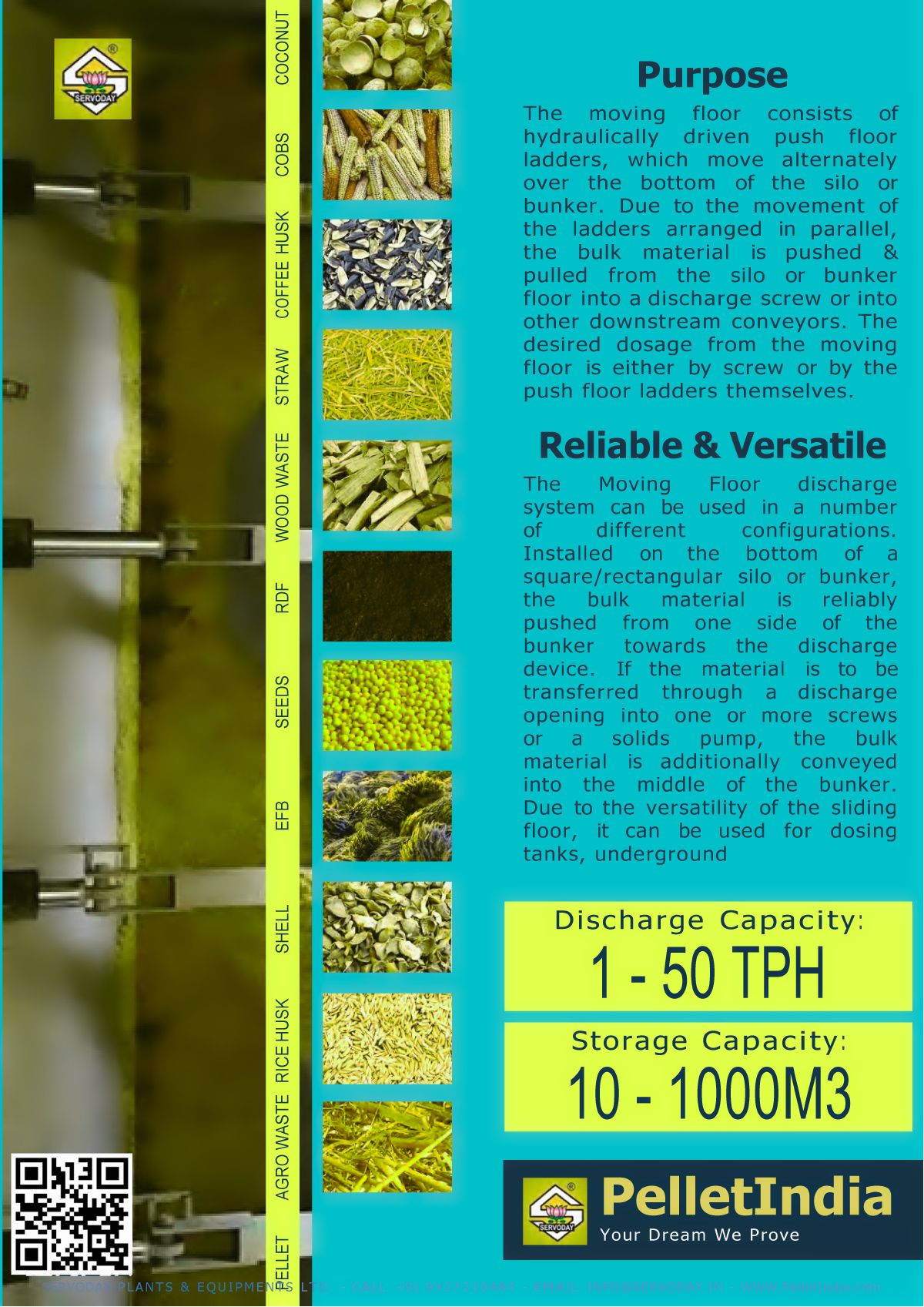

The primary purpose of the Boiler Biomass Feed System is to supply biomass fuels—such as wood chips, sawdust, rice husk, and other residues—to boilers in an efficient and controlled manner. By optimizing the combustion process, this system enhances boiler efficiency, reduces emissions, and ensures continuous operation in industrial heating applications.

Significance

- Efficient Combustion: The system optimizes the fuel supply, leading to effective combustion and better boiler performance.

- Versatile Biomass Handling: Capable of handling multiple types of biomass, ensuring flexibility in fuel selection.

- Cost Reduction and Sustainability: Efficient fuel metering reduces waste, leading to lower operational costs and a smaller environmental footprint.

Key Features

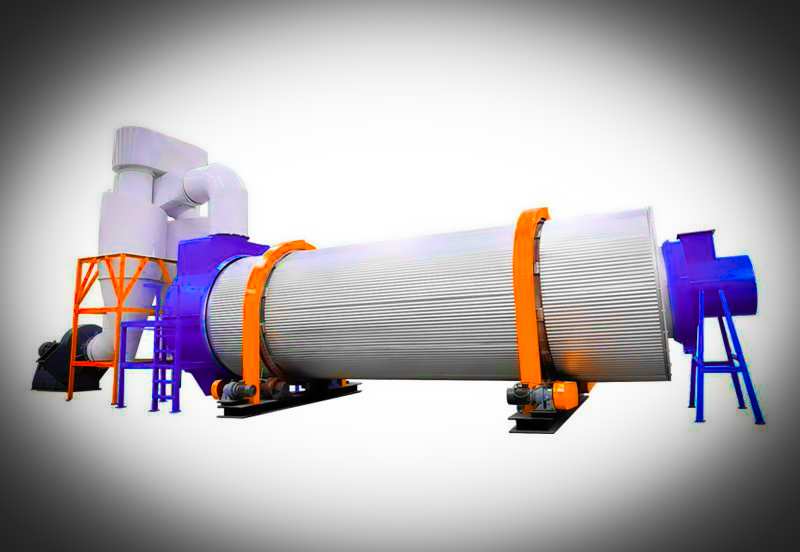

- High Capacity: Handles up to 40 tons per hour, making it suitable for large-scale biomass operations.

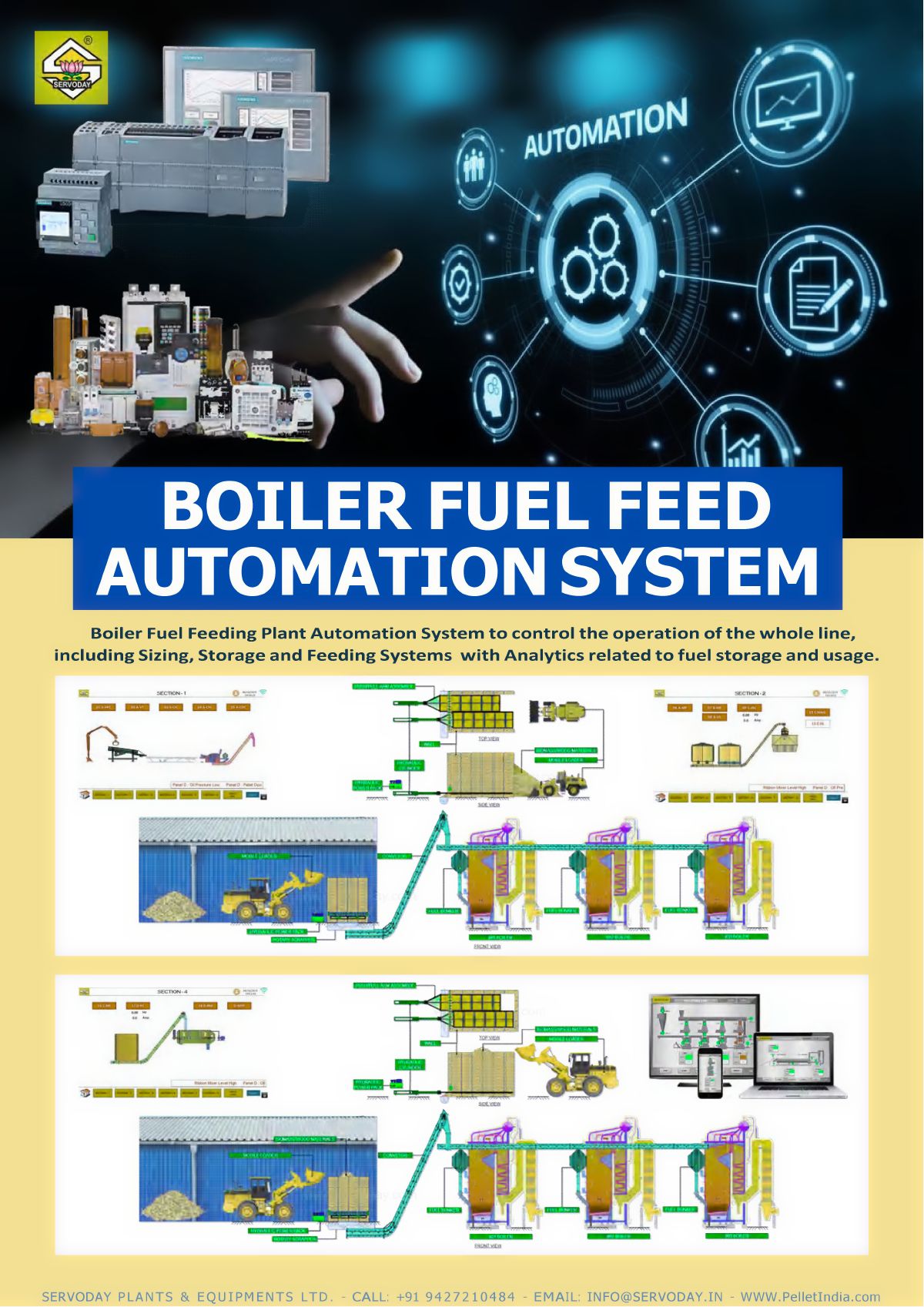

- Advanced Automation: Integrated automation and analytics for fuel storage, feeding, and combustion control, enhancing efficiency and reducing the need for manual intervention.

- Fuel Metering: Gravimetric and volumetric feed controls ensure precise and consistent fuel delivery, optimizing the combustion process.

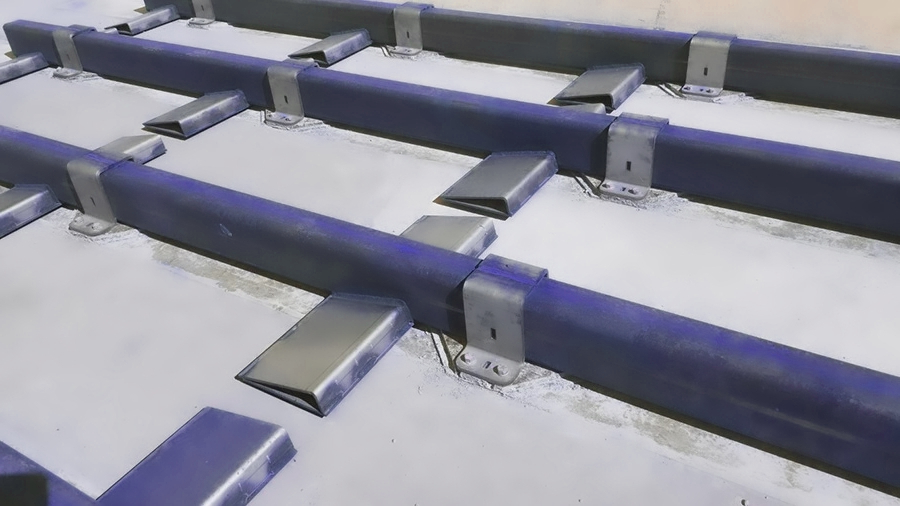

- Multiple Equipment Integration: Includes silos, day bins, distribution screws, metering screws, rotary airlock feeders, and pneumatic injection systems for comprehensive fuel management.

- Safety Features: Equipped with isolation valves, flame monitoring, and fire prevention mechanisms to ensure safe operation.

Unique Aspects

- Flexible Fuel Compatibility: Can handle a wide variety of biomass materials, such as wood chips, sawdust, rice husk, Napier grass, coconut shells, palm husk, and more, making it highly adaptable.

- Comprehensive Solution: Designed to cover the entire fuel feeding process, from storage to combustion, providing a turnkey solution for biomass operations.

- Low Noise and Easy Assembly: Built to operate quietly, with simple installation and assembly, suitable for both retrofit and new installations.

Design Focus

- Optimized Combustion Efficiency: The system is engineered to deliver the exact amount of fuel required for efficient combustion, minimizing emissions and maximizing energy output.

- Safety and Reliability: Emphasis on safety features, such as flame monitoring, isolation valves, and fire dampers, ensures reliable and hazard-free operation.

- Ease of Maintenance: Designed for easy access and maintenance, with components that are straightforward to inspect and clean, reducing downtime.

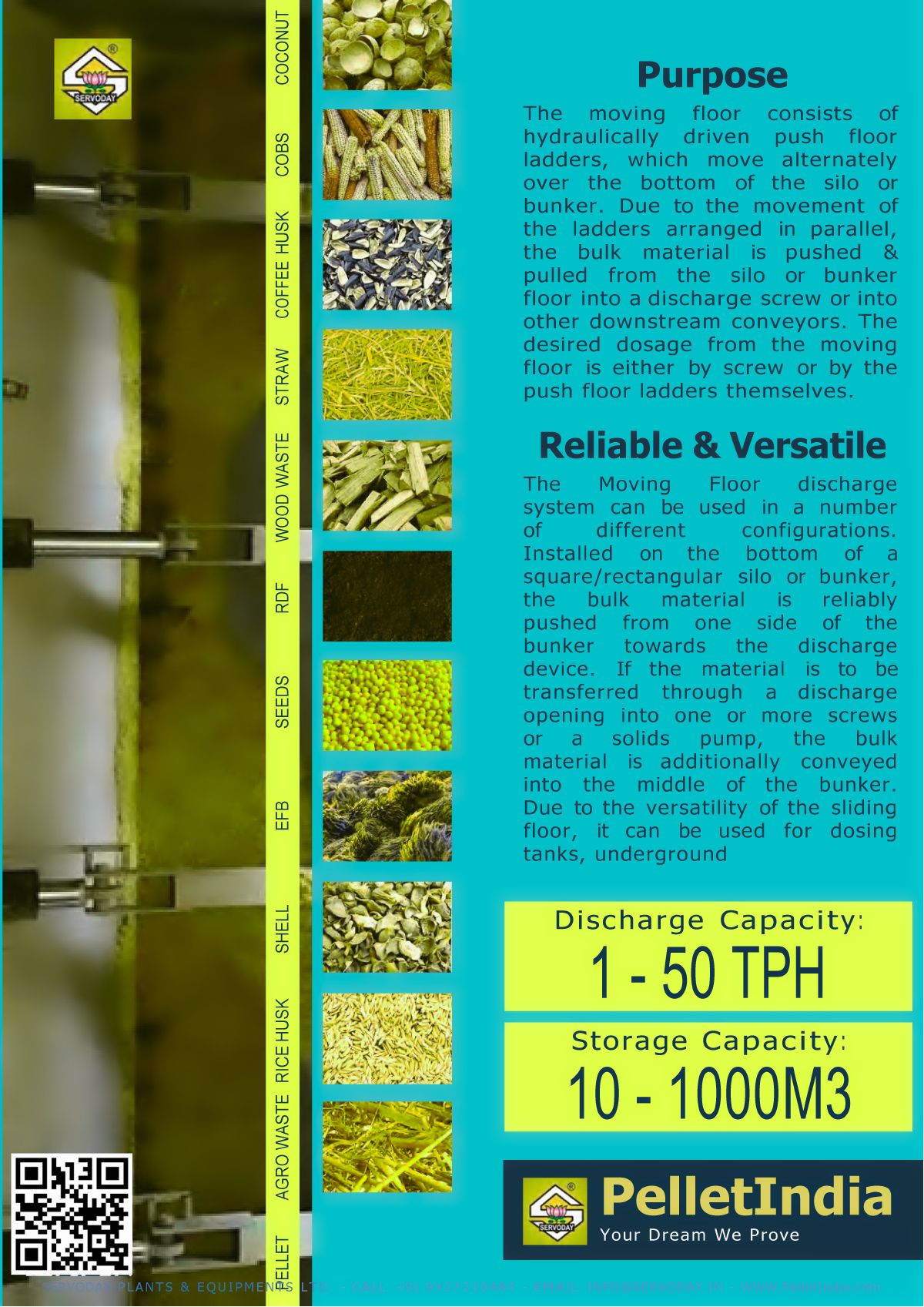

Raw Materials

The Boiler Biomass Feed System can handle a wide range of biomass materials, including:

- Wood Waste: Wood chips, sawdust, bamboo dust, forestry waste.

- Agricultural Residues: Rice husk, wheat straw, paddy straw, corn cobs, palm husk, cotton stalks.

- Other Biomass: Sugarcane bagasse, Napier grass, coconut shells, coffee husk, and other fibrous plant materials.

Output Capacity

- Production Rate: Capable of handling biomass materials at a rate of up to 40 tons per hour, ensuring sufficient feed for large-scale biomass boilers.