Introduction

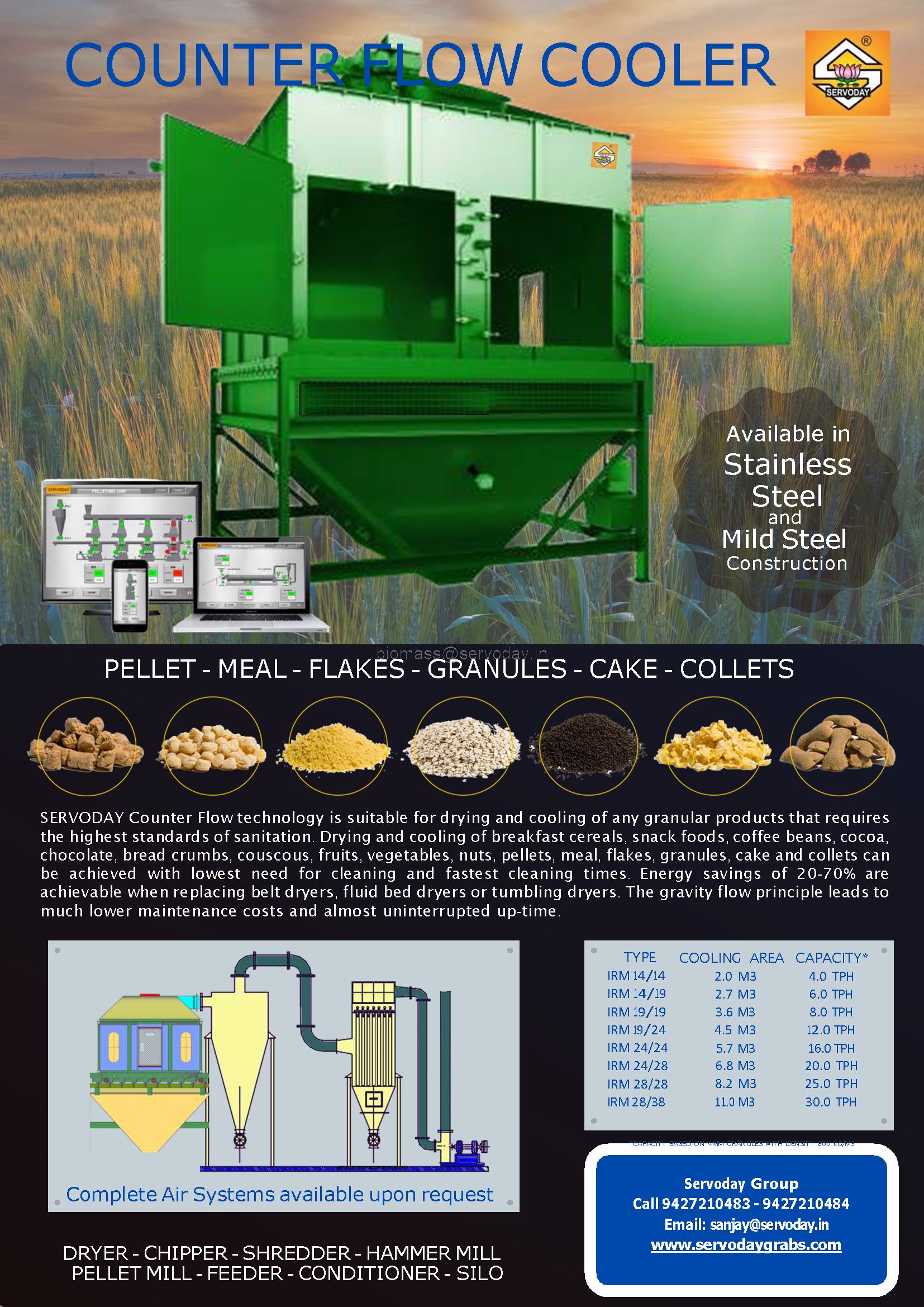

The Biomass Counter Flow Pellet Cooler is an industrial cooling system designed to reduce the temperature of freshly produced biomass pellets. It is an essential component of the pellet production process, helping to solidify pellet structure, enhance durability, and ensure optimal quality for storage and transportation. The cooler works by using counter-current airflow to cool the hot pellets efficiently and evenly.

Overview

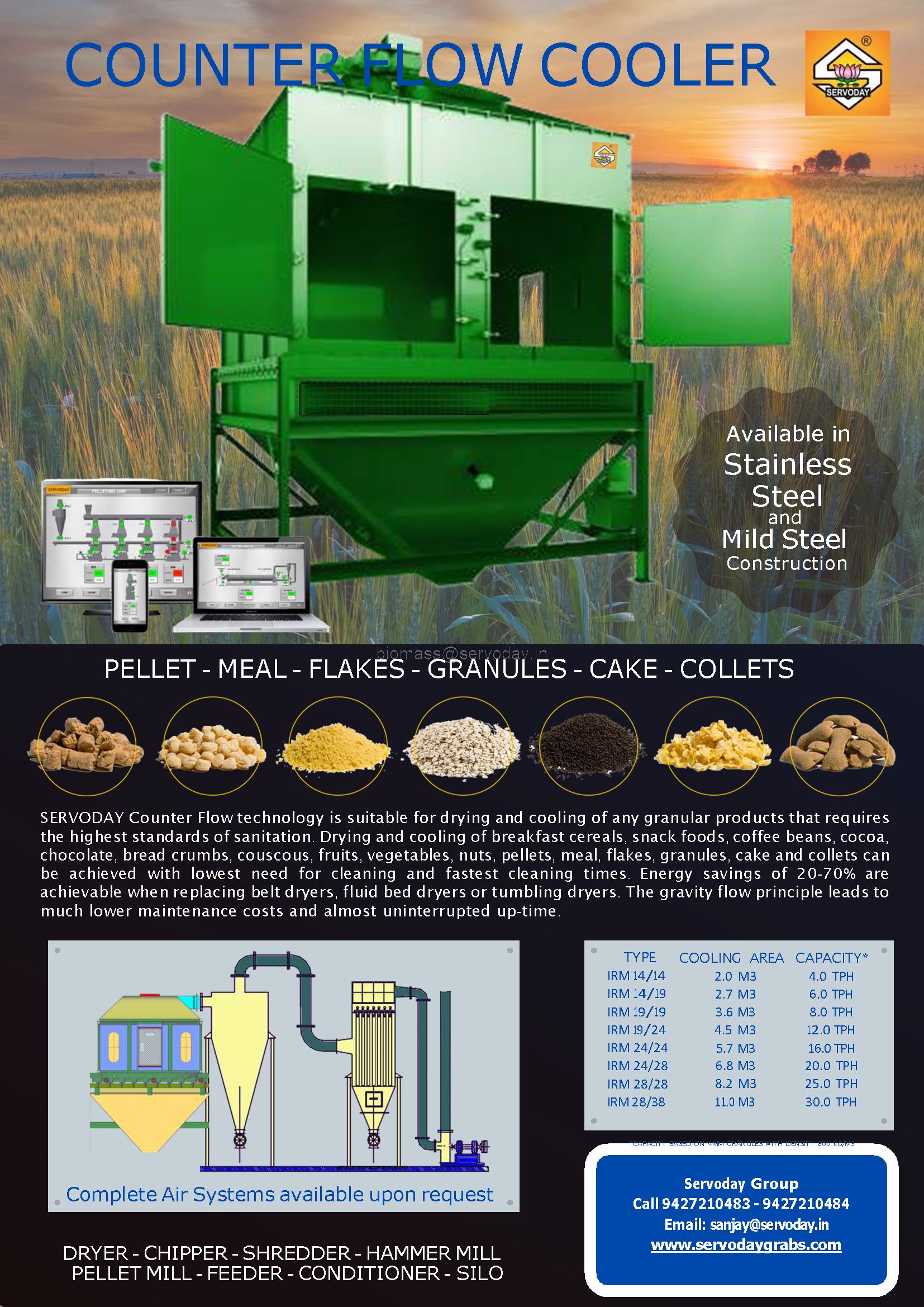

The Biomass Counter Flow Pellet Cooler operates by utilizing counter-current airflow to bring down the temperature of hot pellets. The pellets enter through the top, while cool air flows upwards, effectively reducing the pellet temperature from 70-90°C to about 5-10°C above ambient temperature. The system is designed with a conical bottom and efficient discharge features to ensure homogeneous cooling and minimal pellet breakage.

Purpose

The primary purpose of the Biomass Counter Flow Pellet Cooler is to reduce the temperature of freshly produced pellets and stabilize their moisture content. This cooling process is crucial for ensuring pellet quality, durability, and safe handling. The cooler helps to prevent pellet breakage, condensation, and other quality issues, making it an integral part of the biomass pellet production process.

Significance

- Temperature Control: The cooler effectively reduces pellet temperature to safe levels, ensuring they are easy to handle and suitable for storage.

- Quality Improvement: Proper cooling enhances the quality, durability, and stability of the pellets, reducing the risk of cracking, breakage, and dust formation.

- Moisture Stabilization: Stabilizes moisture content in pellets, preventing condensation and ensuring that the pellets retain their intended properties during storage and transportation.

Key Features

- Counter-Current Cooling: Uses counter-current airflow for efficient temperature reduction, which ensures that pellets are uniformly cooled.

- Conical Bottom Design: Promotes even distribution of hot pellets across the cooler, allowing for a homogeneous product layer and consistent cooling.

- Reduced Pellet Breakage: Features a vibration motor and air cushion system that help pellets flow smoothly, minimizing residues and reducing breakage during discharge.

- Temperature and Level Indicators: Equipped with indicators to monitor the temperature and level of pellets, ensuring precise control of the cooling process.

- High Capacity: Available with a capacity of up to 20 tons per hour, making it suitable for medium to large-scale biomass pellet production operations.

Unique Aspects

- Homogeneous Cooling: The conical bottom design ensures an even distribution of pellets, which, combined with counter-current airflow, delivers consistent and uniform cooling.

- Low Residues and Breakage: The use of air cushions and a vibration motor minimizes pellet breakage and leaves almost no residues, maintaining pellet quality.

- Efficient Discharge System: The modular discharge system is designed for easy assembly and allows for efficient and consistent pellet flow.

Design Focus

- Energy Efficiency: The design optimizes airflow to ensure efficient cooling while using minimal energy, contributing to the overall energy efficiency of the pellet production line.

- Compact and Modular Design: The cooler has a modular structure that makes it easy to assemble, integrate into existing production lines, and maintain.

- Operational Safety: Equipped with temperature indicators and airlocks to ensure controlled pellet entry and safe, effective cooling.

Raw Materials

The Biomass Counter Flow Cooler is used to cool various types of biomass materials formed into pellets, such as:

- Wood Waste Pellets: Sawdust and wood chips.

- Agricultural Residue Pellets: Rice husk, wheat straw, corn cobs, and other agro-residues.

- Other Biomass Pellets: Bagasse, coir pith, bamboo dust, and other fibrous plant residues.

Output Capacity

- Production Rate: Capable of cooling up to 20 tons of pellets per hour, depending on the type of biomass material and pellet properties.