Introduction

The Air Aspiration System is a critical component designed for handling a wide range of biomass materials in pellet production. It ensures efficient material handling by managing airflow and reducing dust, contributing to improved operational efficiency and product quality in biomass pellet plants. The system is fabricated using high-quality raw materials and is built to withstand demanding biomass environments.

Overview

The Air Aspiration System enhances the performance of biomass pellet plants by improving airflow management and ensuring a consistent flow of materials throughout the production process. With a handling capacity of up to 16,000 m³/hr, it plays a vital role in optimizing biomass processing and ensuring consistent pellet quality.

Purpose

The primary purpose of the Air Aspiration System is to enhance the overall efficiency of biomass processing by optimizing airflow management. It reduces dust, improves material flow, and contributes to better pellet quality by maintaining uniform moisture content and density. It is suitable for use in biomass pellet plants that require high standards of material handling efficiency.

Significance

- Enhanced Efficiency: Optimizes material handling by improving airflow, ensuring smooth operations throughout the entire biomass processing line.

- Safety Compliance: Adheres to ATEX regulations, ensuring safe operation in potentially hazardous environments such as hammer mill systems.

- Improved Product Quality: By removing dust and managing airflow, the system helps maintain consistent pellet density and moisture levels, enhancing the overall quality of the final product.

Key Features

- Handling Capacity: Capable of handling up to 16,000 m³/hr, supporting large-scale biomass production.

- Durable Construction: Fabricated with superior raw materials, including components such as gearboxes, motors, and belts from reputed suppliers, ensuring long-term reliability and durability.

- Adjustable Settings: Provides flexibility to accommodate various types of biomass with different moisture contents and particle sizes, ensuring consistent performance.

- Compact Design: Occupies minimal space, optimizing floor space in biomass plants, especially where space availability is limited.

- ATEX Compliance: Built to comply with ATEX regulations for hammer mills, ensuring safety in explosive-prone environments.

Unique Aspects

- Versatility in Material Handling: Suitable for handling all kinds of biomass materials, regardless of density or shape, providing seamless operation across different feedstocks.

- Effective Dust Removal: Enhances pellet quality by removing excess dust and particles from the process flow, contributing to a cleaner production environment.

- Flexible Operation: Adjustable settings allow the system to be tailored for specific requirements, accommodating different biomass materials and optimizing performance.

Design Focus

- Space Efficiency: Designed to occupy minimal floor space, allowing biomass processing facilities to maximize production capacity without expanding physical infrastructure.

- Durability and Safety: Focused on robustness, durability, and compliance with industry safety standards, making it ideal for harsh operational conditions.

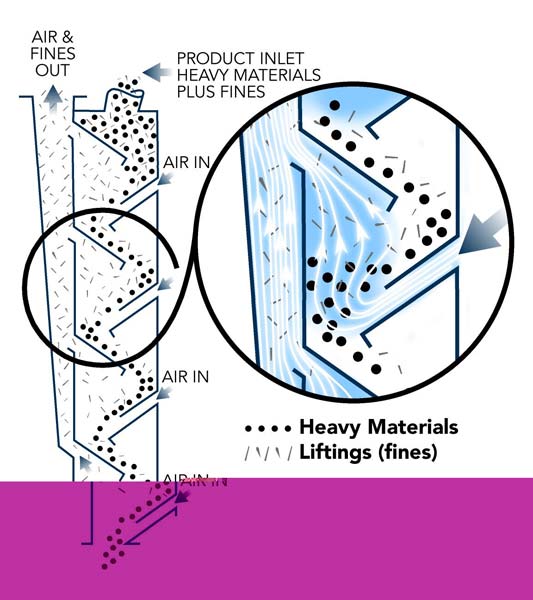

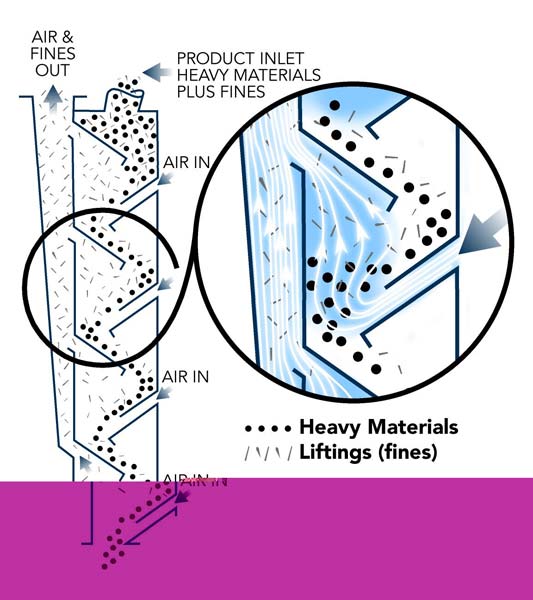

- Optimized Airflow Management: The primary focus of the design is to enhance airflow within the processing line, improving material handling efficiency and ensuring smooth operation.

Raw Materials

The Air Aspiration System can handle a wide range of biomass materials, including:

- Agricultural Residues: Rice husk, wheat straw, paddy straw, corn cobs, sunflower stalks, cotton stalks.

- Wood Waste: Sawdust, wood chips, bamboo dust, forestry waste.

- Other Biomass: Bagasse, coir pith, coffee husk, jute waste, Napier grass, coconut shells, fibrous plant materials.

Output Capacity

- Handling Capacity: Up to 16,000 m³/hr, supporting efficient airflow management for large-scale biomass processing operations.