Pellet Mill Die Bore Specifications Based on Biomass Materials 🌿

🔥 Pellet Mill Die Specifications for Biomass Materials 🔥

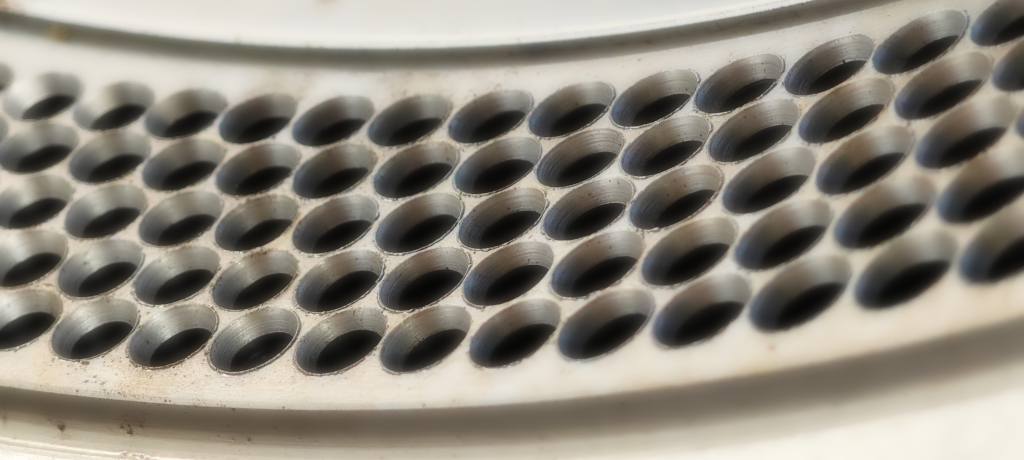

Pellet mill die specifications play a crucial role in optimizing the production process for various biomass materials. The Counter Bore, Compression Bore, and Relief Hole dimensions significantly impact pellet quality, durability, and energy efficiency. Additionally, the Gross Calorific Value (GCV) and Bulk Density are key parameters that determine the combustion efficiency and suitability of pellets for different applications.

Below is a detailed table outlining the ideal die bore specifications for different biomass feedstocks, ensuring maximum performance and efficiency in biomass pellet production.

📌 Which biomass material do you process most?

🌱 Pellet Mill Die Bore Specifications Based on Biomass Materials 🌿

| 🌾 Biomass Material | 📏 Pellet Dia. (mm) | 🔩 Counter Bore Dia. (mm) | 📏 Counter Bore Depth (mm) | 🔩 Comp. Bore Dia. (mm) | 📏 Comp. Bore Length (mm) (L/D Ratio) | 🔩 Relief Hole Dia. (mm) | 📏 Relief Hole Depth (mm) | 🔥 GCV (kcal/kg) | 📦 Density (kg/m³) |

| 🌲 Wood Sawdust | 6 – 8 | 8 – 10 | 3 – 5 | 6 – 8 | 50 – 65 (L/D: 7 – 8) | 6 – 8 | 3 – 5 | 3800 – 4200 | 650 – 750 |

| 🌾 Rice Husk | 6 – 8 | 8 – 10 | 4 – 6 | 6 – 8 | 45 – 60 (L/D: 6 – 7) | 6 – 8 | 4 – 6 | 3000 – 3500 | 550 – 650 |

| 🍬 Bagasse | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 55 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3700 – 4000 | 450 – 550 |

| 🌿 Napier Grass | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 4000 – 4200 | 450 – 550 |

| 🌽 Corn Stalks | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3500 – 3800 | 400 – 500 |

| 🧺 Cotton Stalks | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3800 – 4100 | 400 – 500 |

| 🥜 Groundnut Shells | 6 – 8 | 8 – 10 | 4 – 6 | 6 – 8 | 45 – 60 (L/D: 6 – 7) | 6 – 8 | 4 – 6 | 4000 – 4200 | 600 – 700 |

| 🌾 Wheat Straw | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3500 – 3800 | 350 – 450 |

| 🌰 Mustard Husk & Stalk | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3400 – 3700 | 350 – 450 |

| 🎍 Bamboo Dust | 6 – 8 | 8 – 10 | 4 – 6 | 6 – 8 | 50 – 65 (L/D: 7 – 8) | 6 – 8 | 4 – 6 | 4000 – 4300 | 650 – 750 |

| 🌴 Palm Husk | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3500 – 3900 | 500 – 600 |

| 🍵 Tea Waste | 8 – 10 | 10 – 12 | 5 – 7 | 8 – 10 | 40 – 50 (L/D: 5 – 6) | 8 – 10 | 5 – 7 | 3600 – 4000 | 450 – 550 |

📢 Why These Specifications Matter?

✅ Pellet Diameter & Counter Bore: Determines the final pellet size and smooth extrusion.

✅ Compression Bore Length & L/D Ratio: Affects pellet durability, density, and production efficiency.

✅ Relief Hole & Depth: Prevents blockage, ensures smooth die operation.

✅ Gross Calorific Value (GCV): Higher GCV means better combustion efficiency and energy output.

✅ Bulk Density: Higher density pellets are easier to transport, store, and burn efficiently.

By selecting the right die bore specifications, you can enhance production efficiency, reduce maintenance costs, and maximize pellet fuel quality.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥