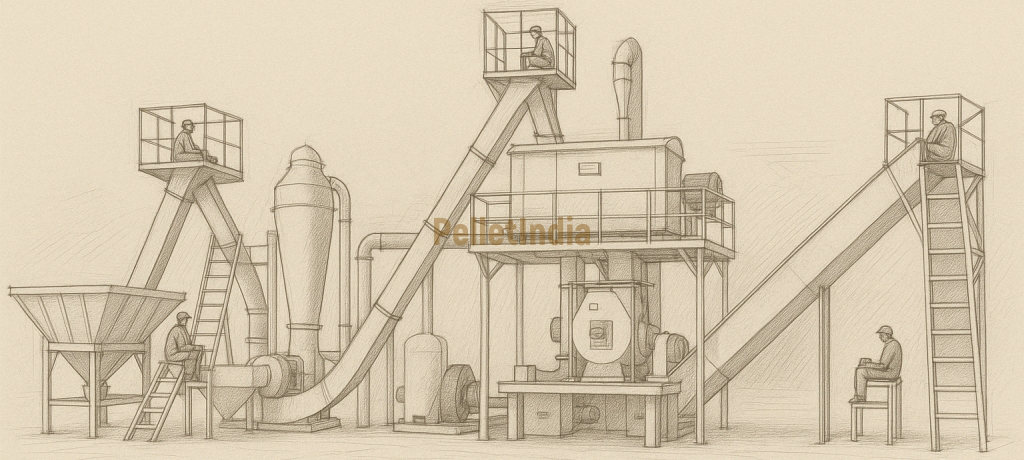

🌱 Inside a PelletIndia Fully Automated Biomass Pellet Plant: Key Machinery & Layout

PelletIndia’s 5 TPH Fully Automated Biomass Pellet Plant is a cutting-edge facility designed for high efficiency, minimal human intervention, and consistent pellet quality. This real-world setup integrates smart automation, heavy-duty equipment, and an energy-efficient layout to ensure 24/7 operation with only 2 operators per shift. 🔧 Key Machinery in the 5 TPH Fully Automated Pellet […]

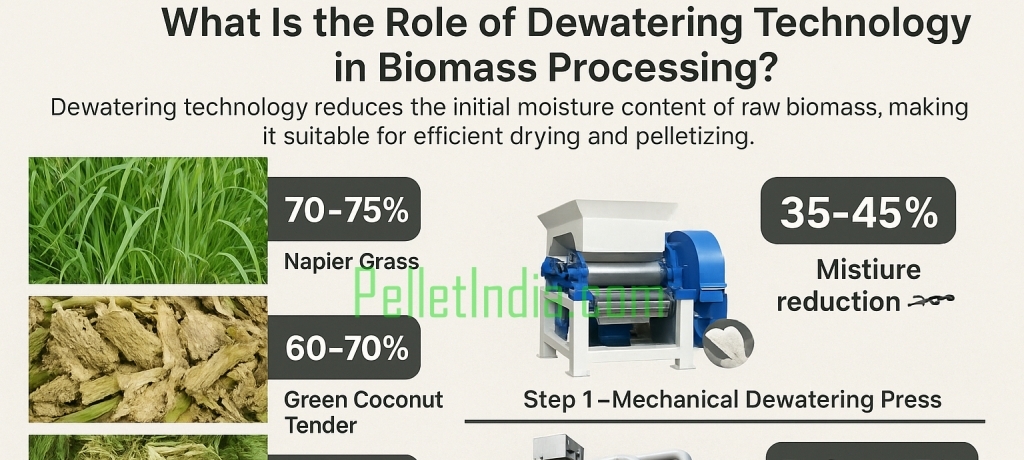

♻️ What Is the Role of Dewatering Technology in Biomass Processing?

Dewatering technology plays a crucial role in the biomass pellet-making process by reducing the initial moisture content of raw biomass materials, making them suitable for efficient drying and pelletizing. Many high-moisture raw materials—such as Napier Grass, sugarcane bagasse, and green coconut husk—contain 65% to 75% moisture, which is too high for direct pellet production. To […]

🧪 Understanding Volatile Matter and Its Impact on Biomass Combustion:

Volatile Matter (VM) plays a critical role in the combustion characteristics of biomass fuels. It refers to the portion of biomass (excluding moisture) that vaporizes when the material is heated to high temperatures in the absence of oxygen. These volatile compounds—mainly hydrocarbons, hydrogen, carbon monoxide, and other light gases—ignite and combust quickly, significantly influencing the […]

🏭 What Machinery Is Essential for Setting Up a Biomass Pellet Plant?

Setting up a biomass pellet plant involves a series of processes to convert raw biomass into uniform, high-density pellets used for fuel, heating, or industrial energy. Below is a detailed breakdown of essential machinery required, along with how PelletIndia, a division of Servoday Plants & Equipments Limited, can support you throughout the journey. 🔧 Essential […]

🌿 Where to Buy Super Napier Grass (SNG): Best Suppliers, Prices, and Turnkey Support from PelletIndia

Super Napier Grass is a high-yield, hybrid fodder and biomass crop 🌾 used across India for livestock feeding 🐄, pellet production 🔥, and bio-CNG generation 💨. If you’re exploring where to buy Super Napier Grass (SNG), compare suppliers, and understand its benefits, this guide is your one-stop resource — with full turnkey support from PelletIndia.com […]