Introduction

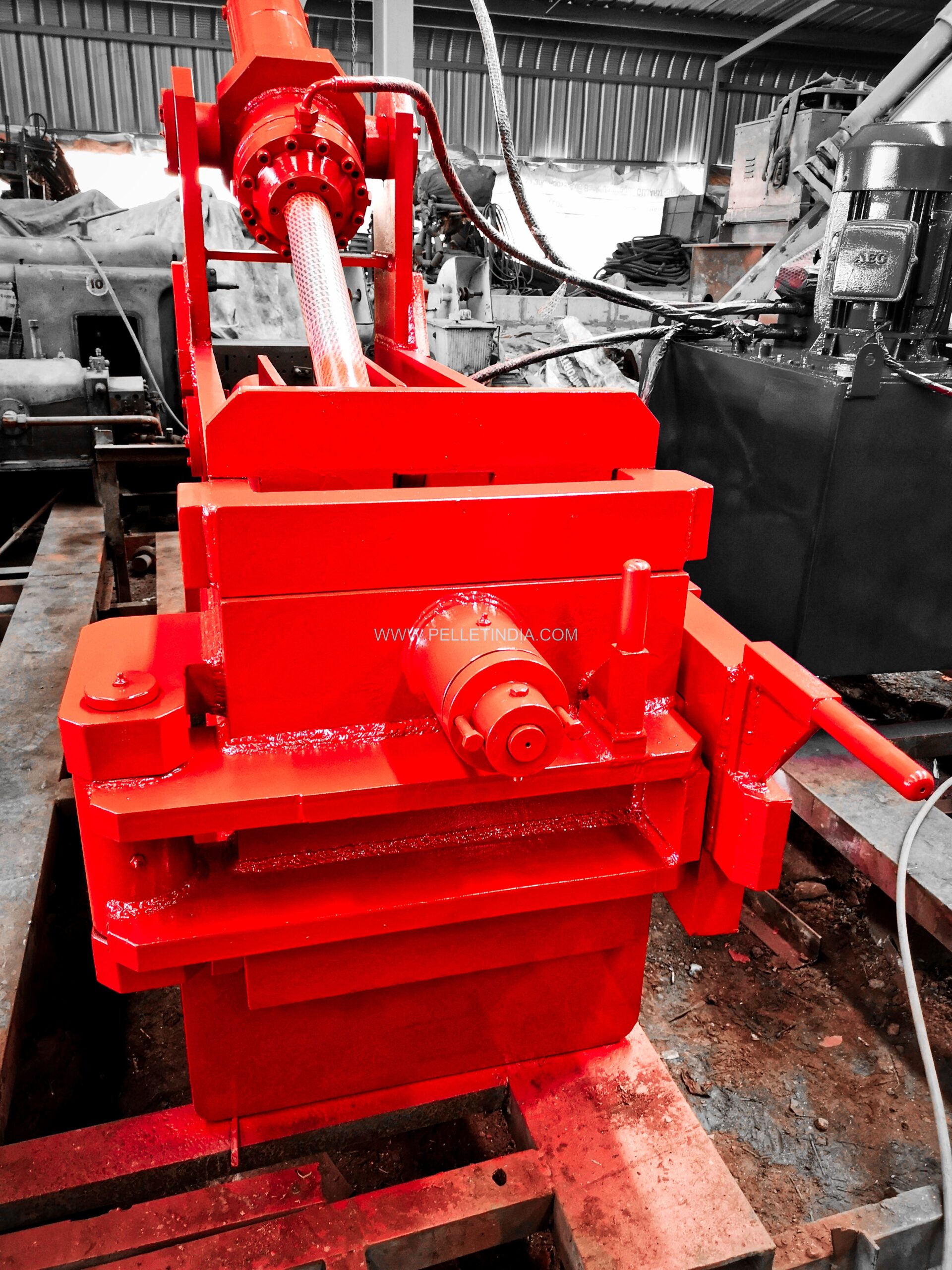

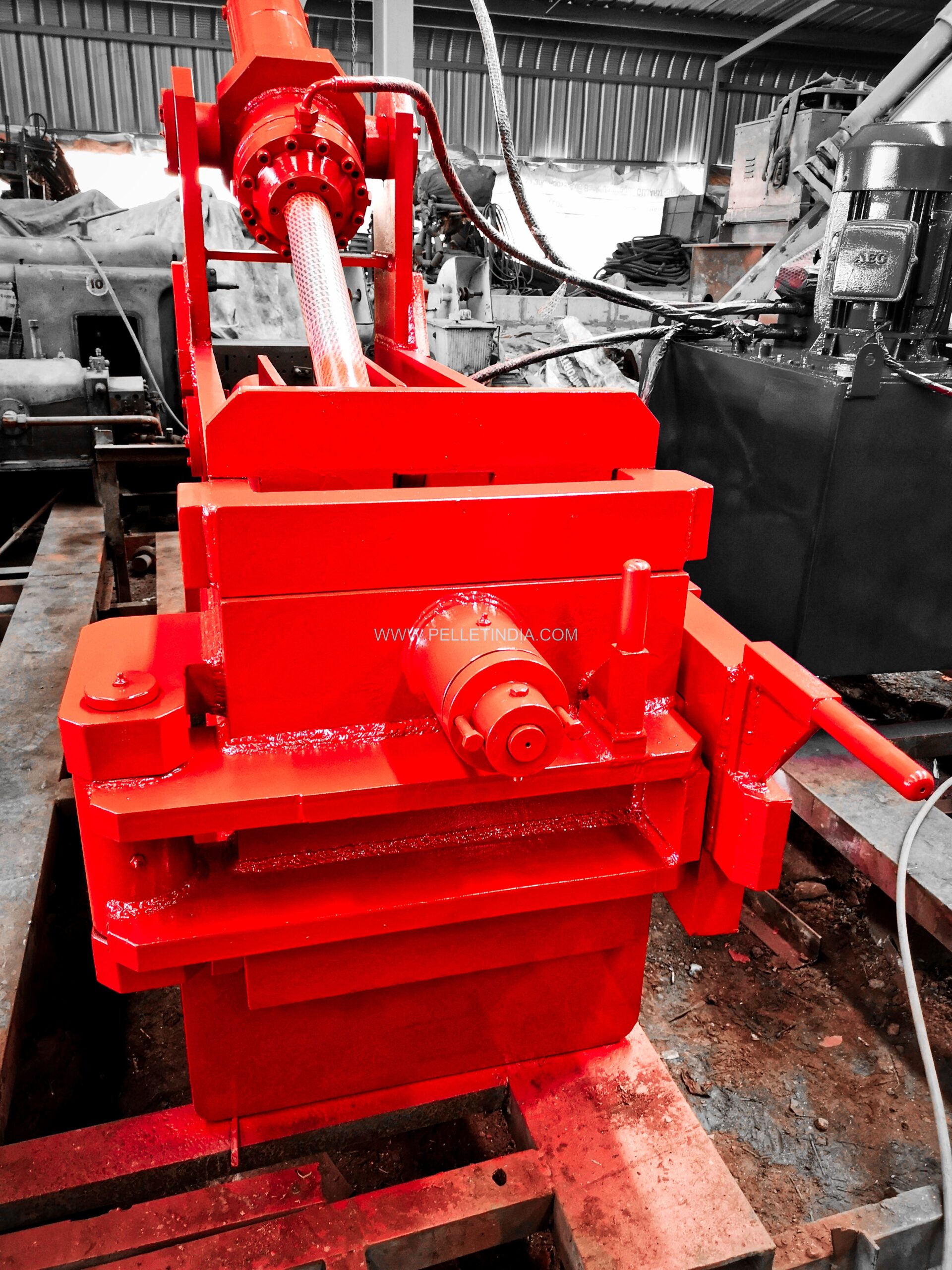

The Baling Press for Metal Scrap is a hydraulic machine designed to compress scrap metals and waste materials into dense, manageable blocks. It is capable of handling both ferrous and non-ferrous metals, making it a versatile tool for recycling and waste management.

Overview

This baling press reduces the volume of metal scrap, making it more efficient to store, transport, and recycle. The machines come in both semi-automatic and automatic versions, catering to different operational needs. It is used across various industries, including scrap yards, rolling mills, and manufacturing units.

Purpose

The purpose of the Baling Press is to compact metal scrap and waste into high-density bales to reduce transportation and storage costs while facilitating easier handling for recycling processes.

Significance

The Baling Press provides an effective solution for managing scrap metal, helping industries save on space, transportation, and labor costs. By compressing metal waste, it contributes to more sustainable waste management practices and reduces the environmental impact of metal production.

Key Features

- Hydraulic machine capable of compressing ferrous and non-ferrous metals

- Available in heavy-duty continuous, triple-action, double-action, single-action, mobile, and vertical models

- Offers both semi-automatic and automatic options

- Designed to accommodate specific scrap management needs, including type of scrap, quantity, and required productivity

- Compact bales for reduced storage and transportation costs

Unique Aspects

The Baling Press comes with a variety of automation options and customization features to suit individual customer requirements. Its flexibility in processing both ferrous and non-ferrous metals sets it apart, making it suitable for diverse industries and applications.

Design Focus

The design of the Baling Press emphasizes space-saving, efficiency, and versatility. It includes features such as triple-action compression, which applies pressure from three directions for maximum density, and mobile units that offer flexibility by allowing the press to be moved as needed.

Raw Materials

- Input: Ferrous and non-ferrous metals, including steel, copper, zinc, iron, stainless steel, aluminum, and other metal alloys

- Material of Construction: Heavy-duty steel components to ensure durability and reliability

Output Capacity

- Produces high-density bales suitable for efficient storage, transportation, and recycling

- Available in different configurations to handle various volumes of scrap