Introduction

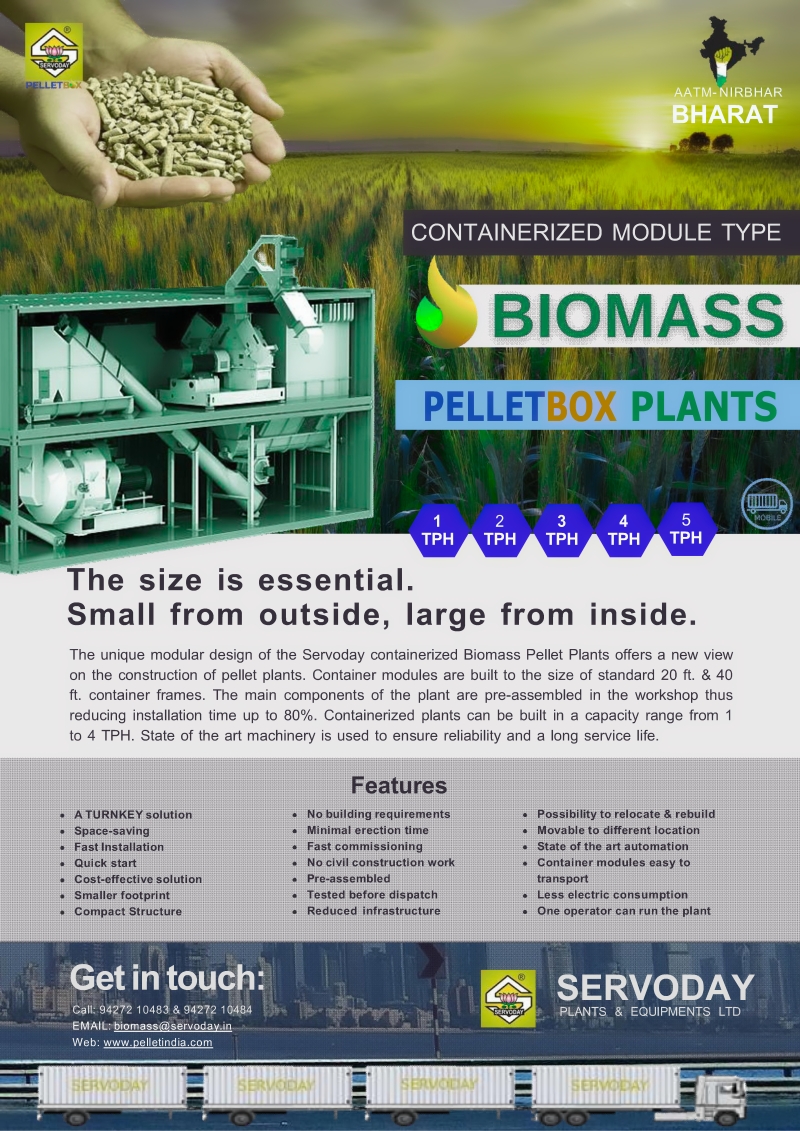

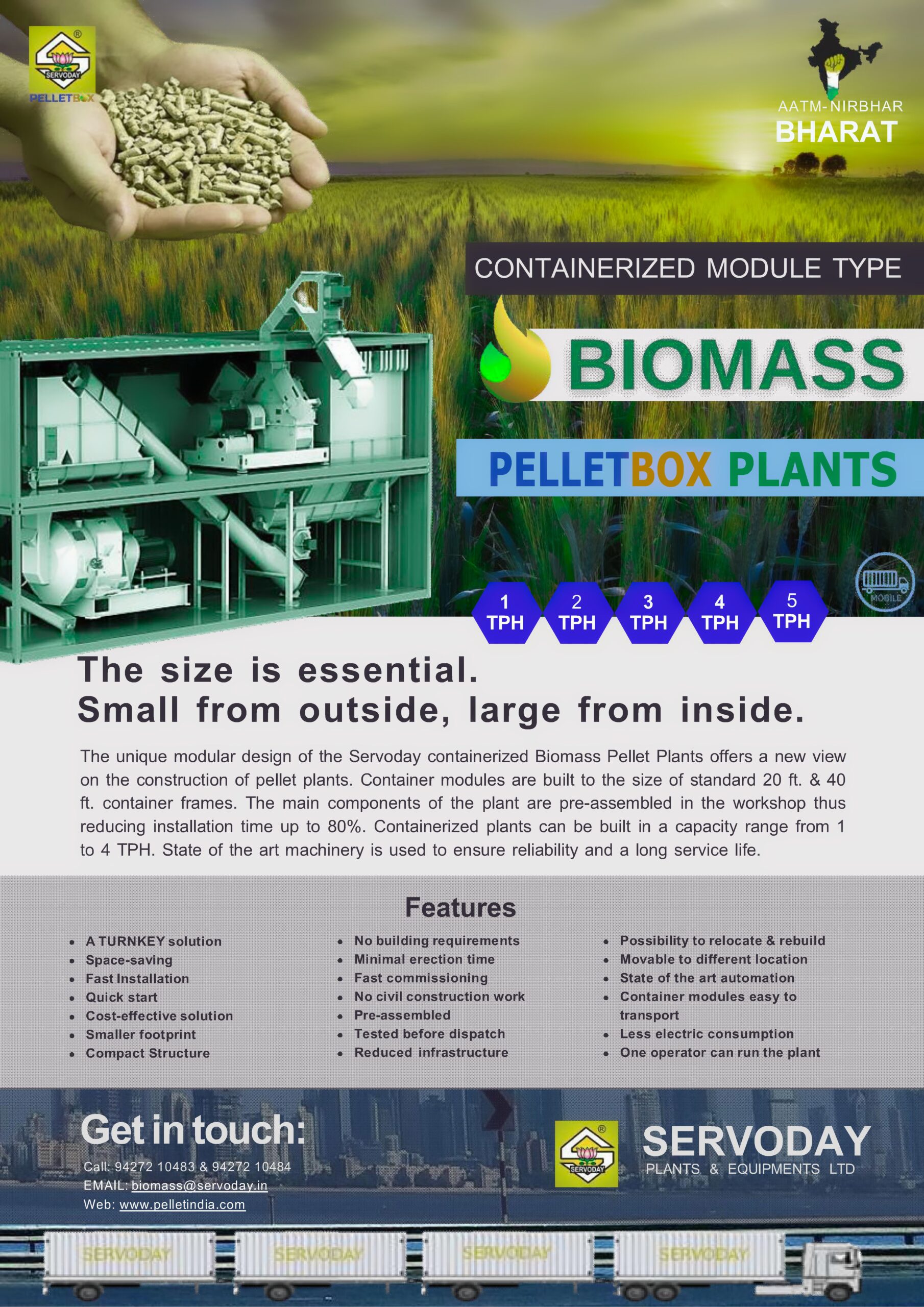

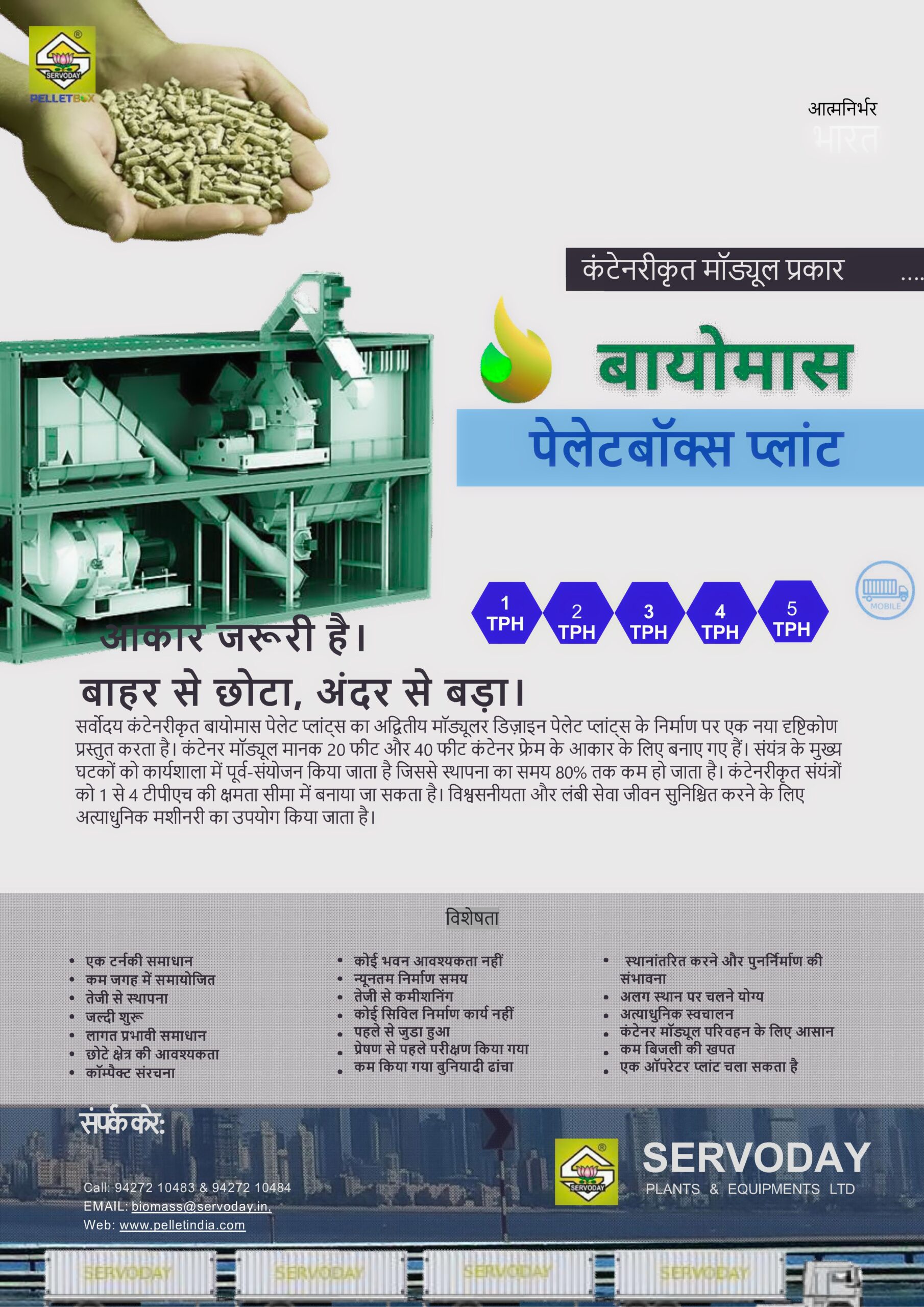

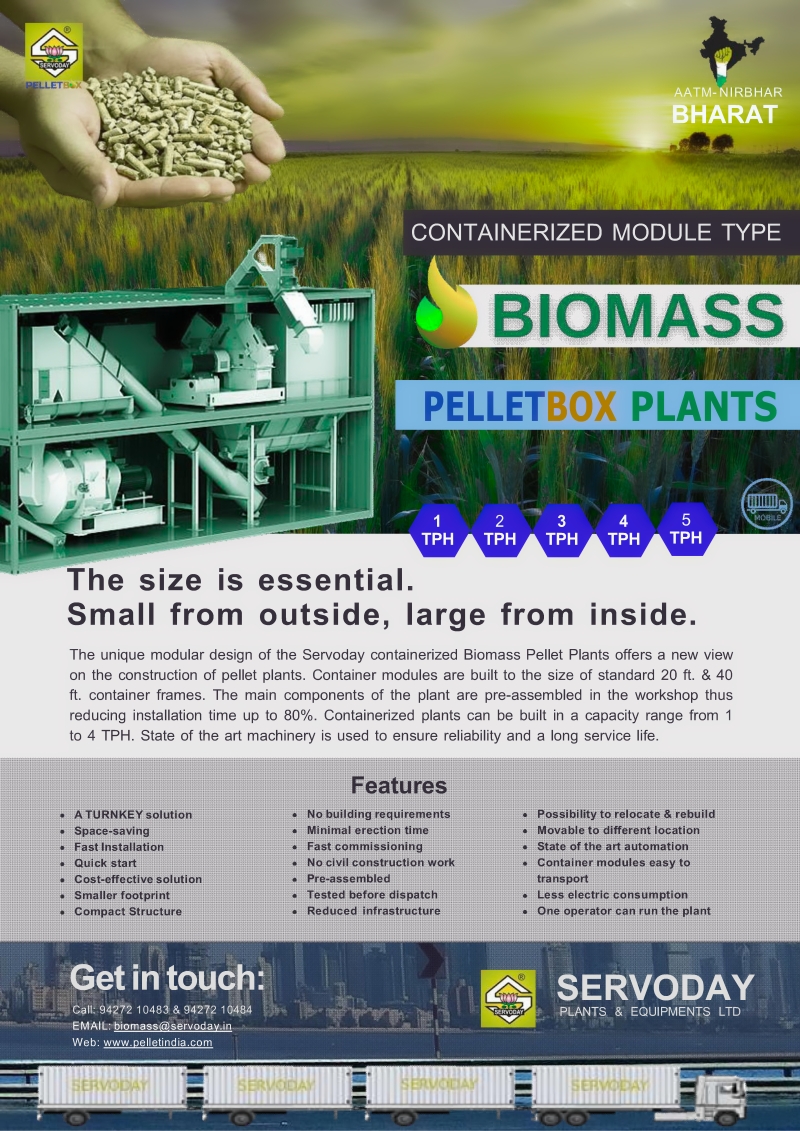

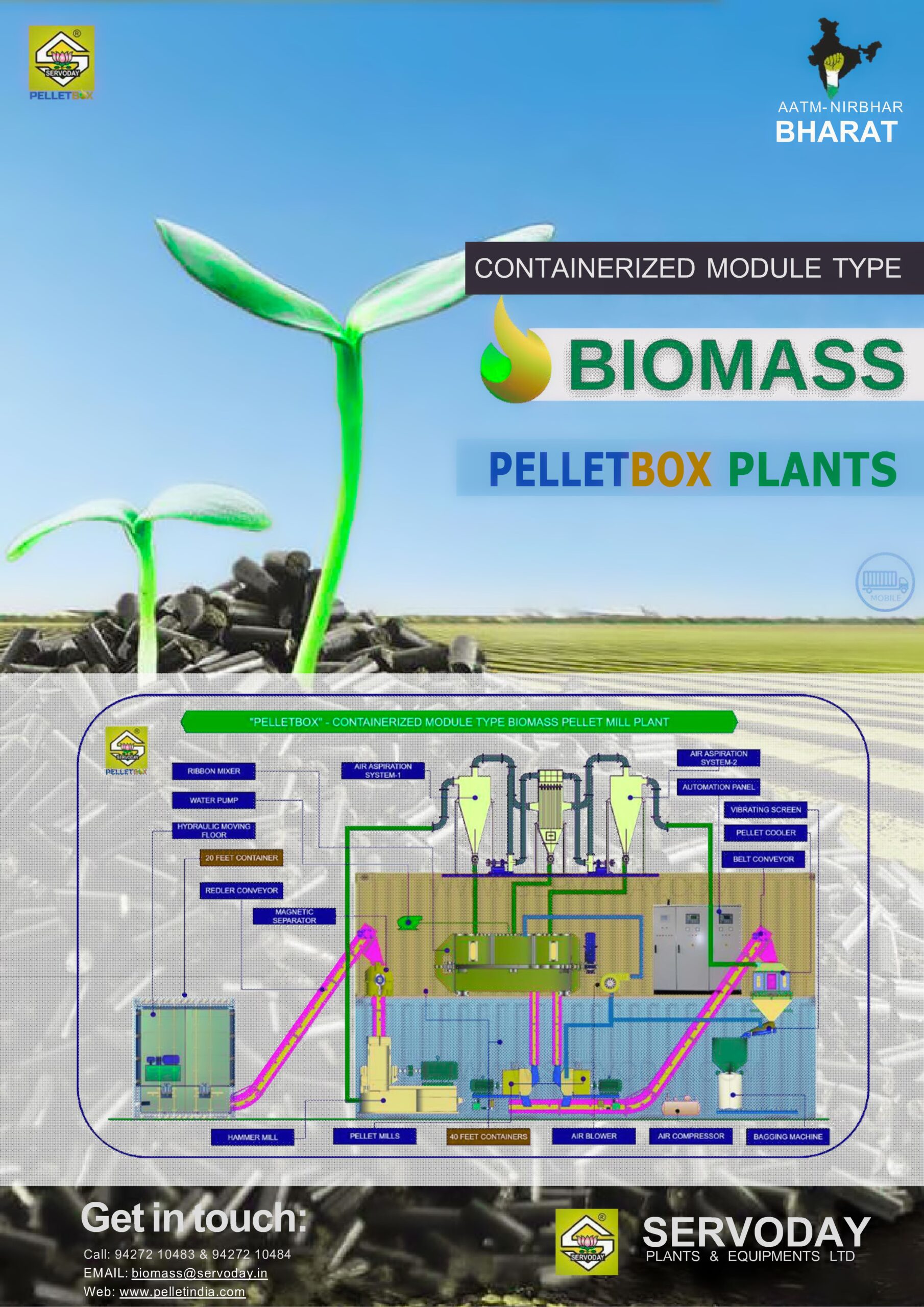

The Wood Biomass Mobile Pellet Plant is a compact and portable pelletizing facility designed for the on-site production of biomass pellets. This plant is engineered to produce biomass pellets from a wide variety of raw materials, offering mobility and flexibility in biomass processing, making it suitable for remote locations or temporary operations.

Overview

The Mobile Pellet Plant is a self-contained unit that integrates all necessary equipment for biomass pellet production within a compact, portable structure. It is designed to process raw biomass materials directly on-site, minimizing the need for transporting bulky materials. With a capacity of 1-2 tons per hour, this plant is ideal for small to medium-scale operations and is specifically targeted at applications where mobility and flexibility are critical.

Purpose

The primary purpose of the Wood Biomass Mobile Pellet Plant is to facilitate decentralized, on-site pellet production from biomass raw materials, which can then be used as renewable energy sources or animal feed. This plant provides an efficient solution for processing agricultural and forestry residues at the point of biomass generation.

Significance

- On-Site Processing: Allows biomass to be processed directly where it is generated, reducing the need for transportation and the associated costs.

- Decentralized Production: Supports decentralized energy production, especially in remote or off-grid locations where traditional pellet production facilities may not be accessible.

- Adaptability: The plant is suitable for small-scale enterprises and farm managers looking to produce biomass pellets without investing in permanent infrastructure.

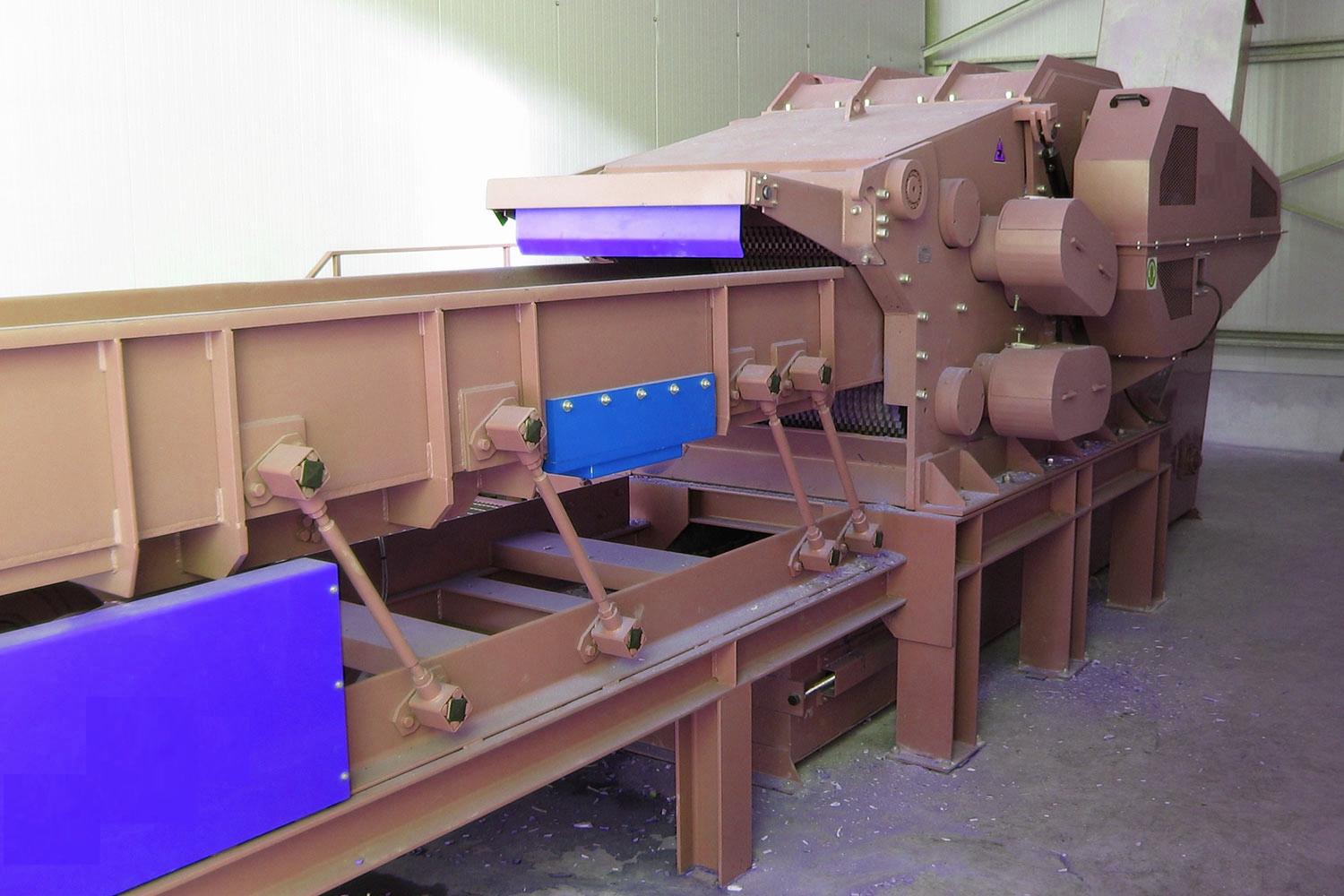

Key Features

- Portability: Housed in a container, making it easy to transport and relocate as needed, especially beneficial for mobile farm managers or temporary projects.

- Compact Design: Optimized to ensure efficient use of space while maintaining production capabilities of 1-2 tons per hour.

- Cost-Efficiency: Provides an affordable alternative to large-scale pellet plants, with a focus on keeping infrastructure and operational costs low.

- Automation: Equipped with higher levels of automation, reducing manpower requirements and ensuring smooth operation.

Unique Aspects

- Mobility: The entire production unit is mobile, allowing it to be relocated based on biomass availability. This feature makes it ideal for temporary or seasonal biomass processing needs.

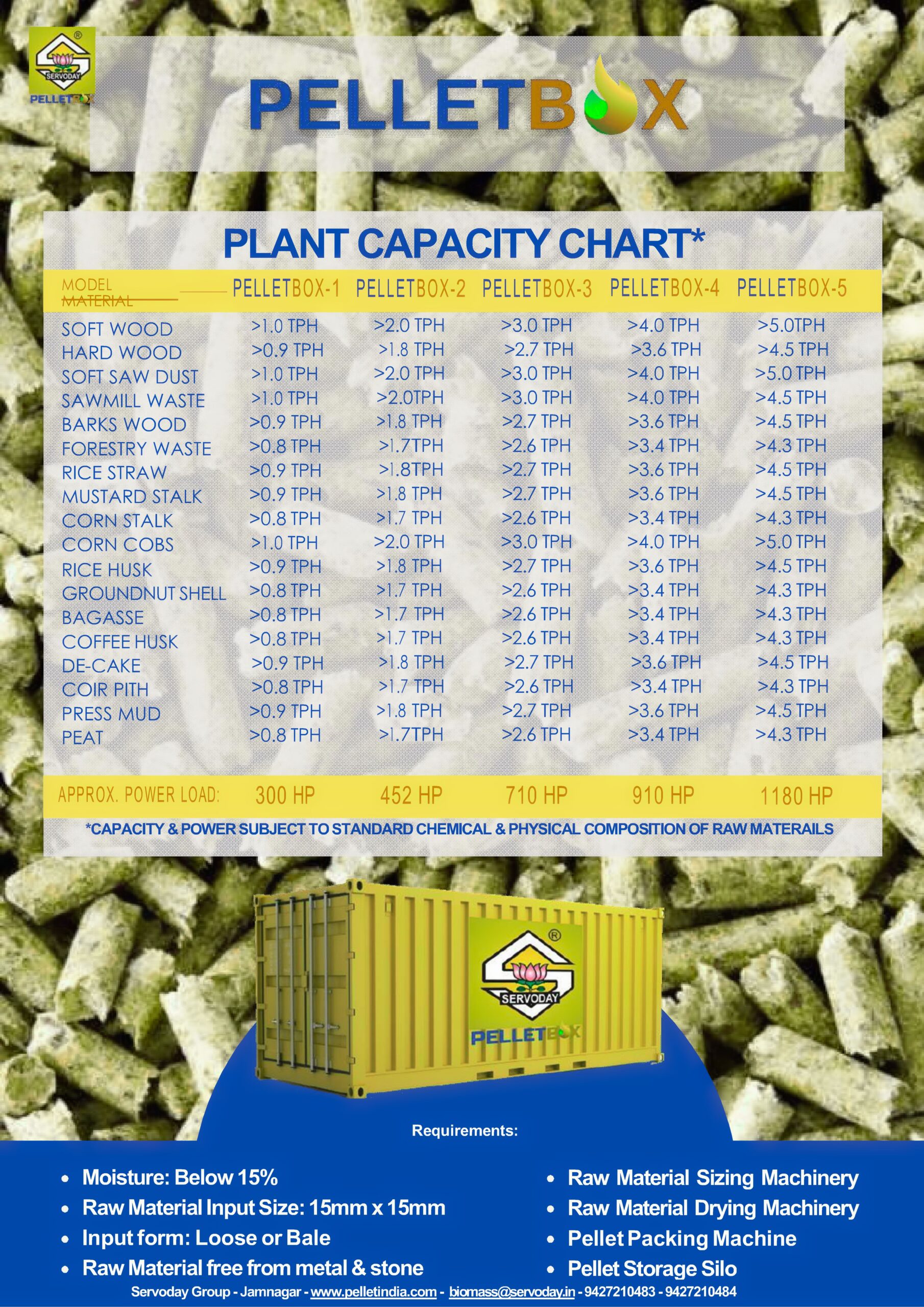

- Versatile Raw Material Handling: Capable of processing various biomass materials, such as wood, sawdust, corn stalks, and straw, offering flexibility in feedstock and output types (e.g., wood pellets or animal feed pellets).

- Quick Deployment: Designed for quick setup and commissioning, allowing for rapid deployment, especially in emergency situations or remote areas.

Design Focus

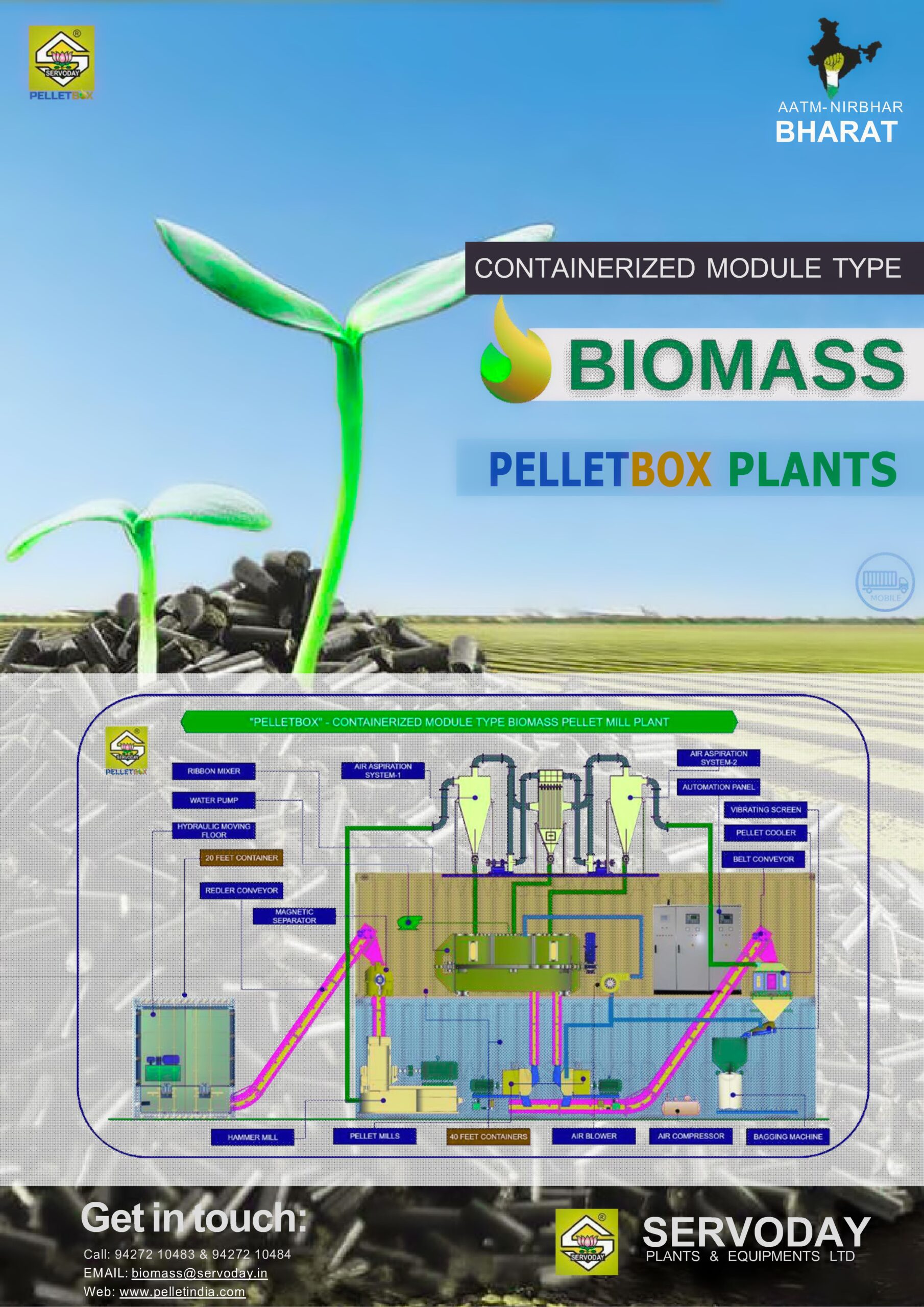

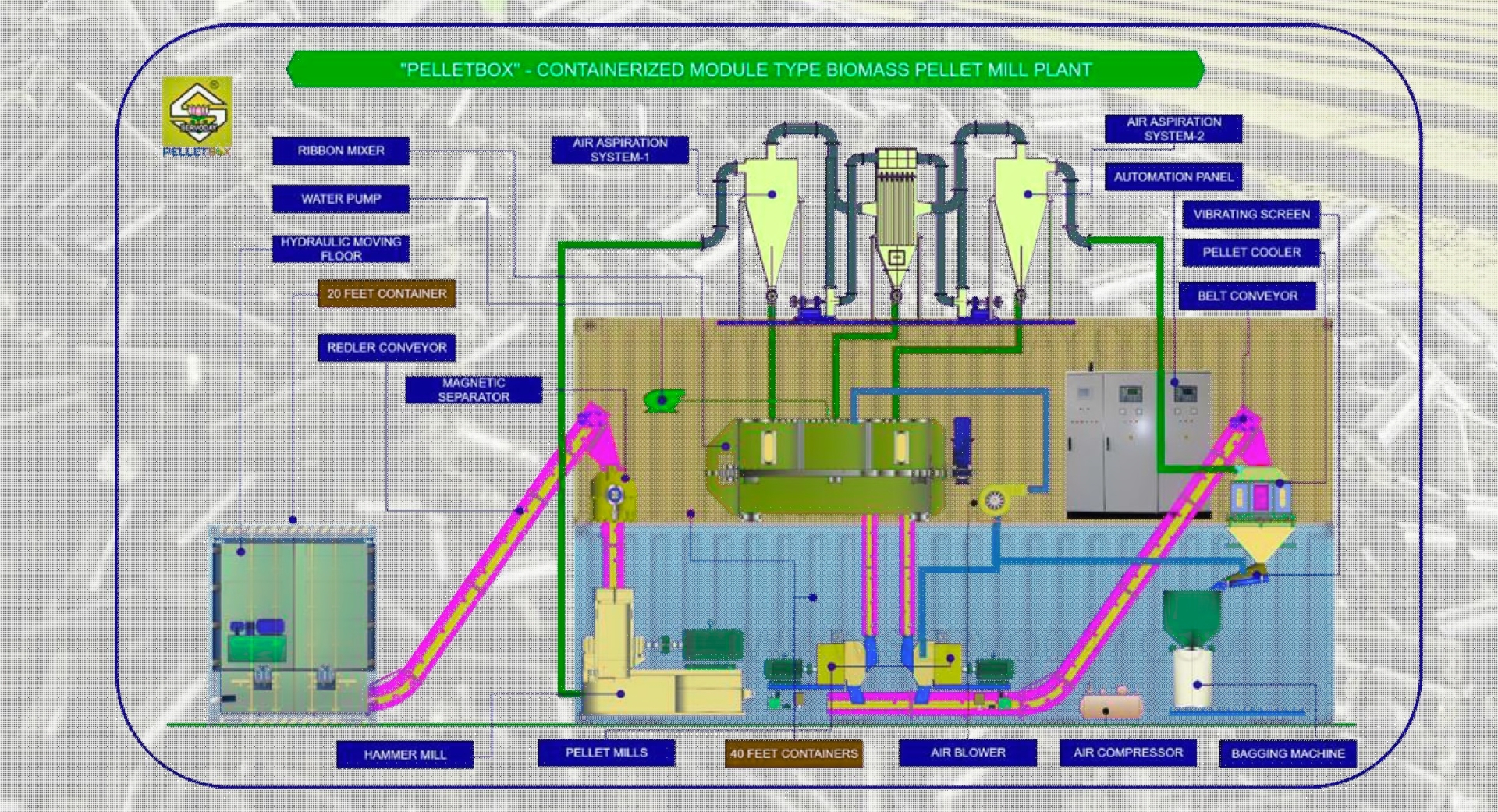

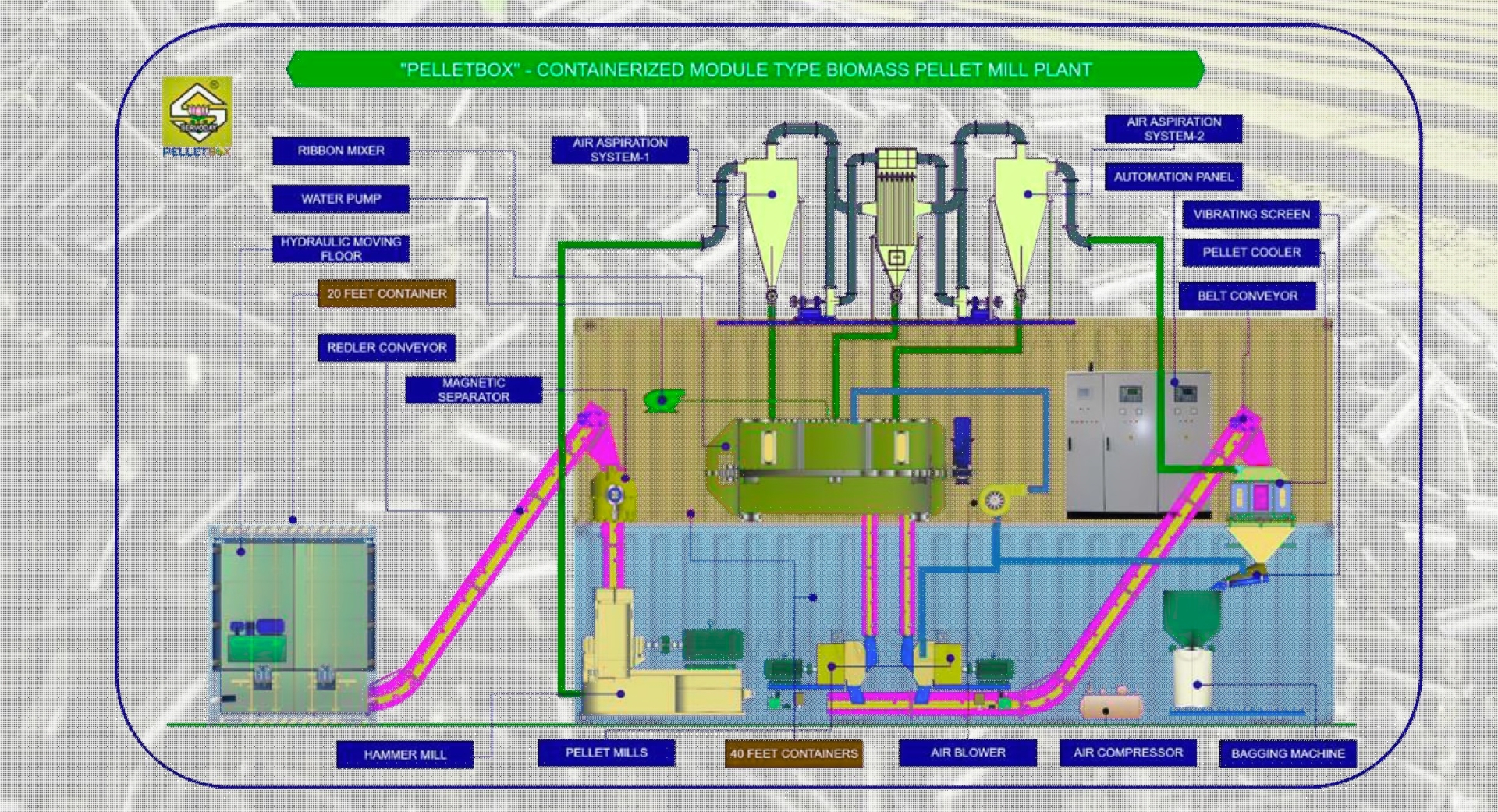

- Efficiency and Automation: Emphasis on automation and compact design to ensure efficient pellet production while minimizing labor input.

- Versatile Configuration: Flexible to group different equipment depending on specific processing needs, allowing customization for varied biomass feedstock.

- Compact, Containerized Layout: The equipment is arranged in a containerized format, making it easy to transport and providing a complete solution for pellet production in a single unit.

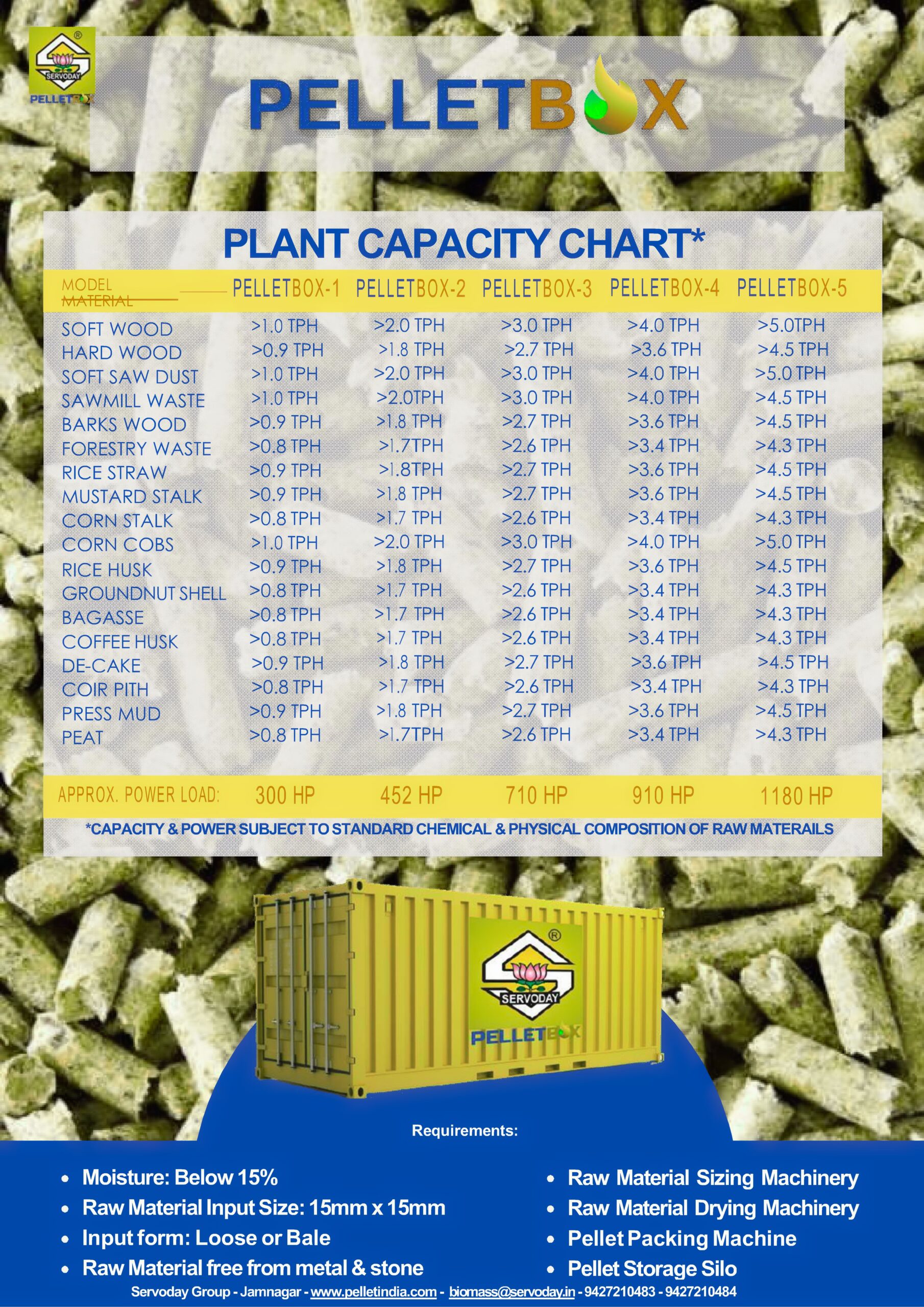

Raw Materials

The Mobile Pellet Plant can process a wide range of biomass materials, including:

- Agricultural Residues: Bagasse, rice husk, wheat straw, paddy straw, corn cobs, coconut wastes, groundnut shells, sunflower stalks, etc.

- Forestry Residues: Sawdust, wood chips, bamboo dust, mulberry sticks, forestry waste, etc.

- Other Biomass: Coffee husk, castor seed shell, coir pith, palm husk, jute waste, and more.

Output Capacity

- Production Rate: Capable of producing 1-2 tons of biomass pellets per hour, suitable for small to medium-scale operations and flexible production needs.