Introduction

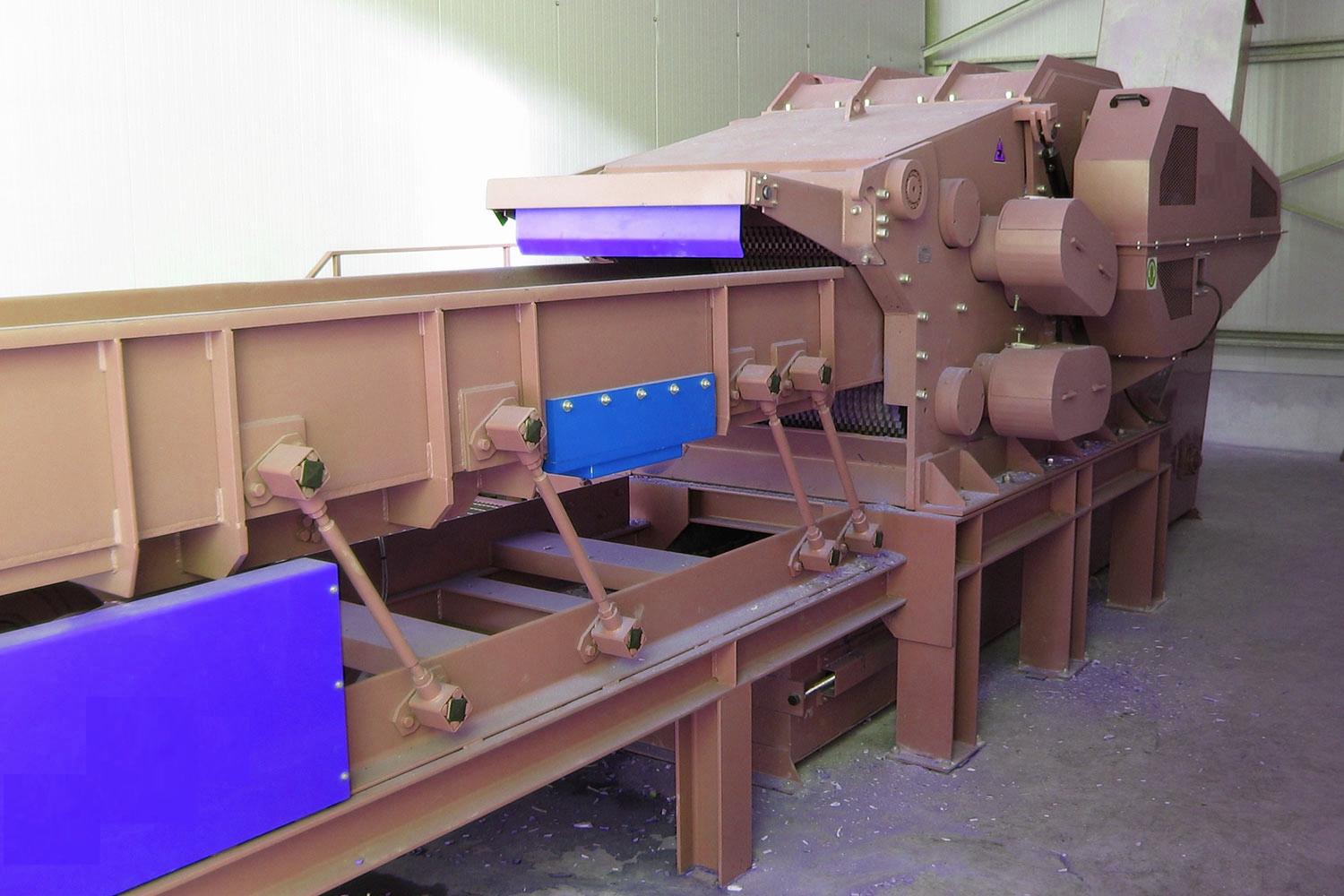

The Ring Die Pellet Mill is a robust and efficient pelletizing machine designed for producing pellets from wood, feed, and biomass materials. It features a high-efficiency ring die design that allows for continuous operation in demanding conditions. This machine is ideal for both small-scale and large-scale pellet production, suitable for a wide range of applications, including energy production, animal feed, and industrial use.

Overview

The Ring Die Pellet Mill combines fresh engineering and the latest manufacturing technology to deliver superior performance in pellet production. It utilizes a ring die type design to ensure high-capacity output and durability under continuous operation. With a capacity range of 1-5 tons per hour, this pellet mill is built to meet diverse needs across the biomass and feed sectors.

Purpose

The primary purpose of the Ring Die Pellet Mill is to convert biomass, wood, and other materials into high-quality pellets. These pellets are used as renewable energy sources for heating and power generation, animal feed, and industrial applications. The machine ensures consistent pellet quality, making it suitable for commercial and industrial uses.

Significance

- Versatility in Applications: The pellet mill is capable of producing a wide range of pellets, including biomass fuel, animal feed, and wood pellets, making it adaptable for various industries.

- Sustainable Energy Production: Helps in the conversion of waste materials into renewable energy, contributing to environmental sustainability.

- Cost-Effective Production: Designed for 24-hour operation, ensuring high productivity and efficiency, which translates into cost savings for large-scale producers.

Key Features

- Capacity Range: Produces 1 to 5 tons of pellets per hour, making it suitable for both small and large-scale production.

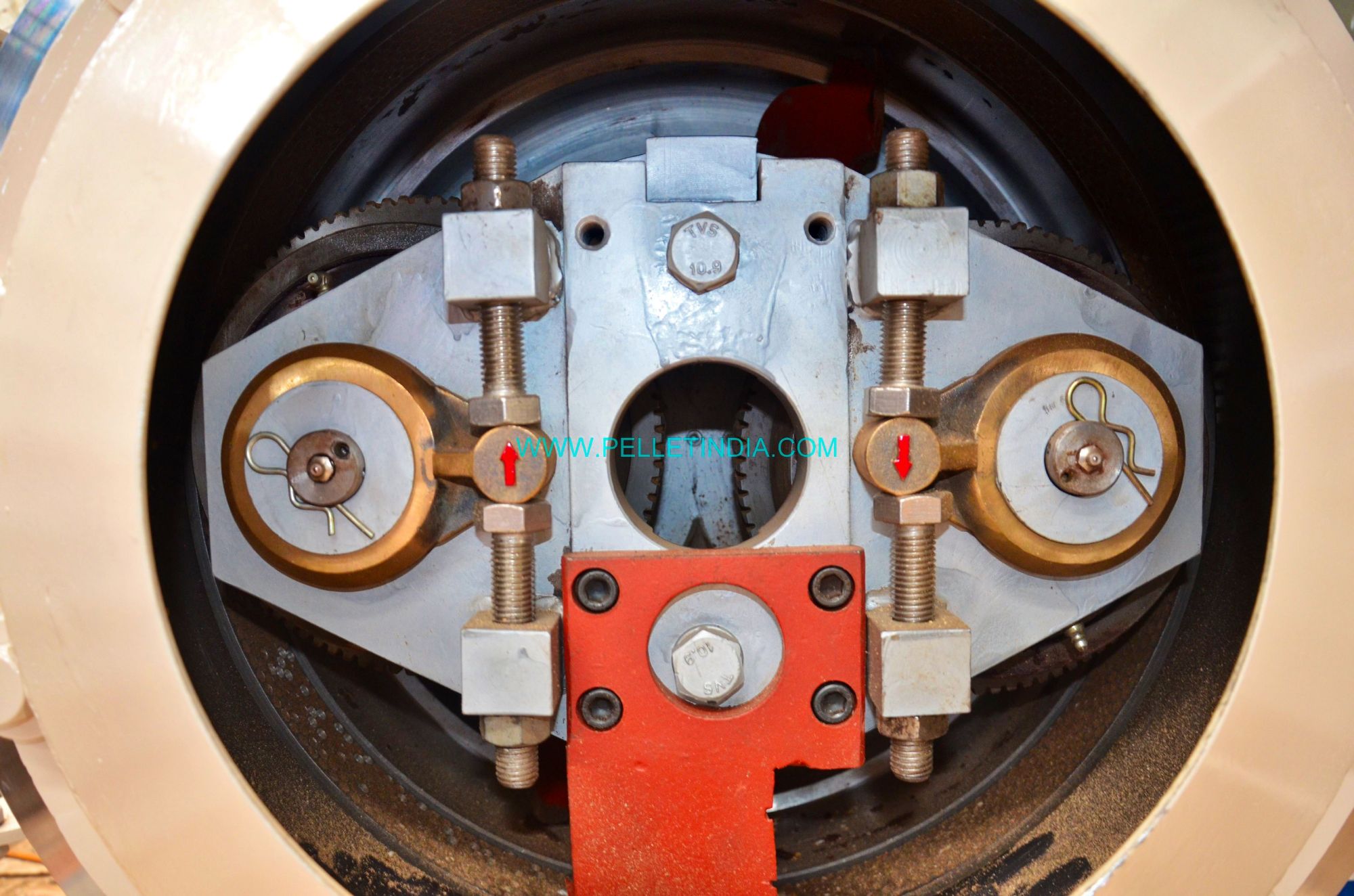

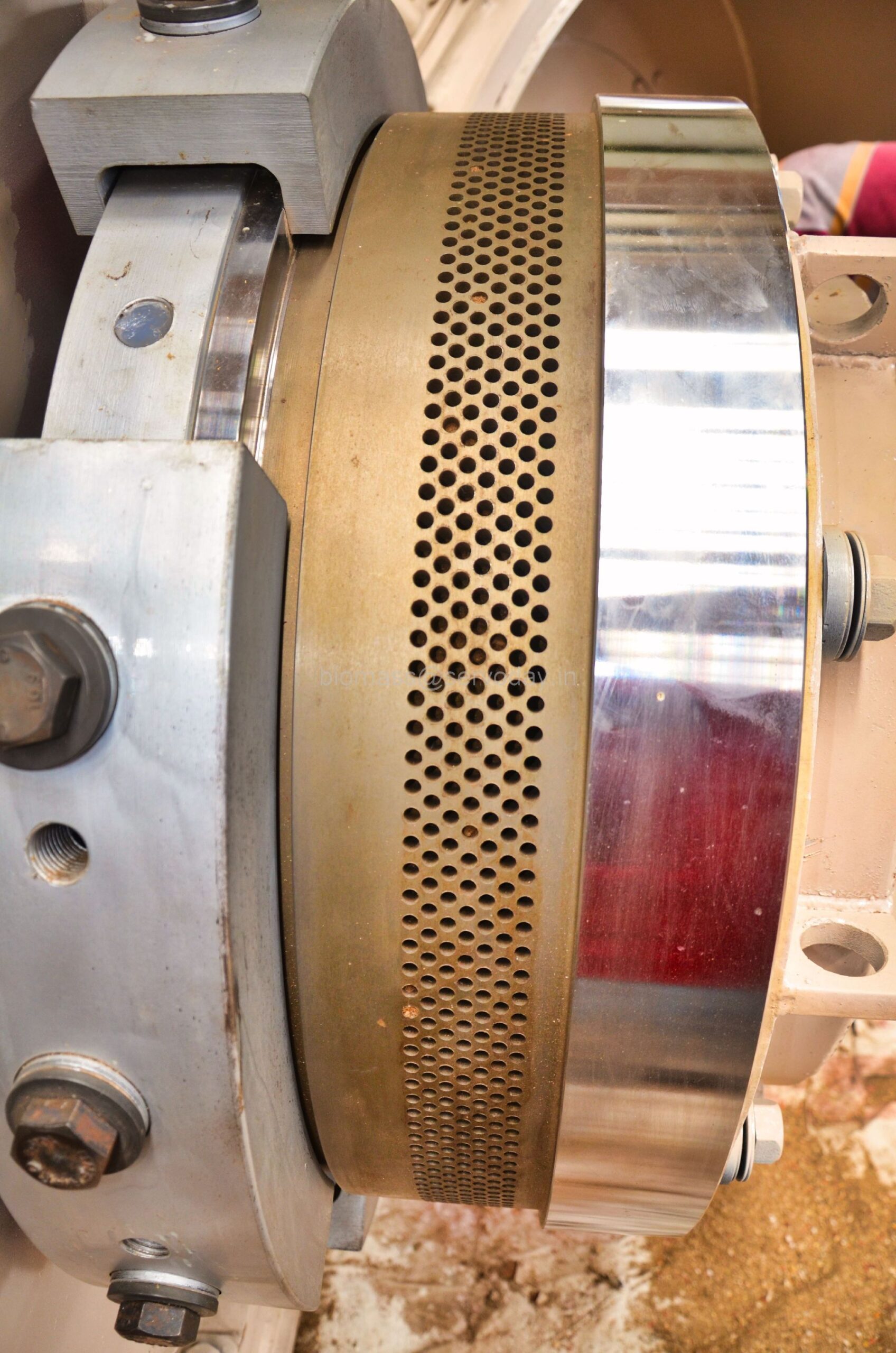

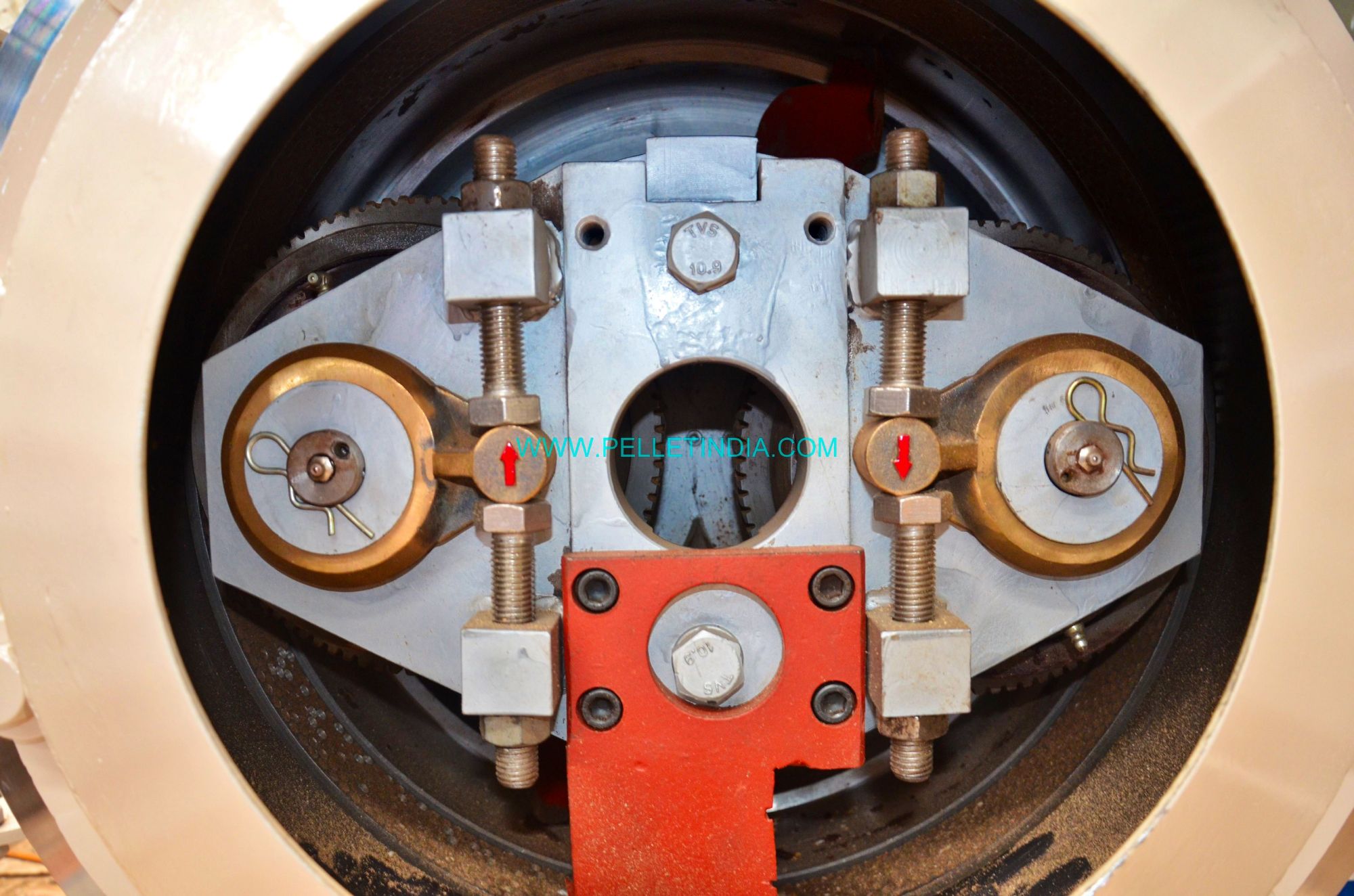

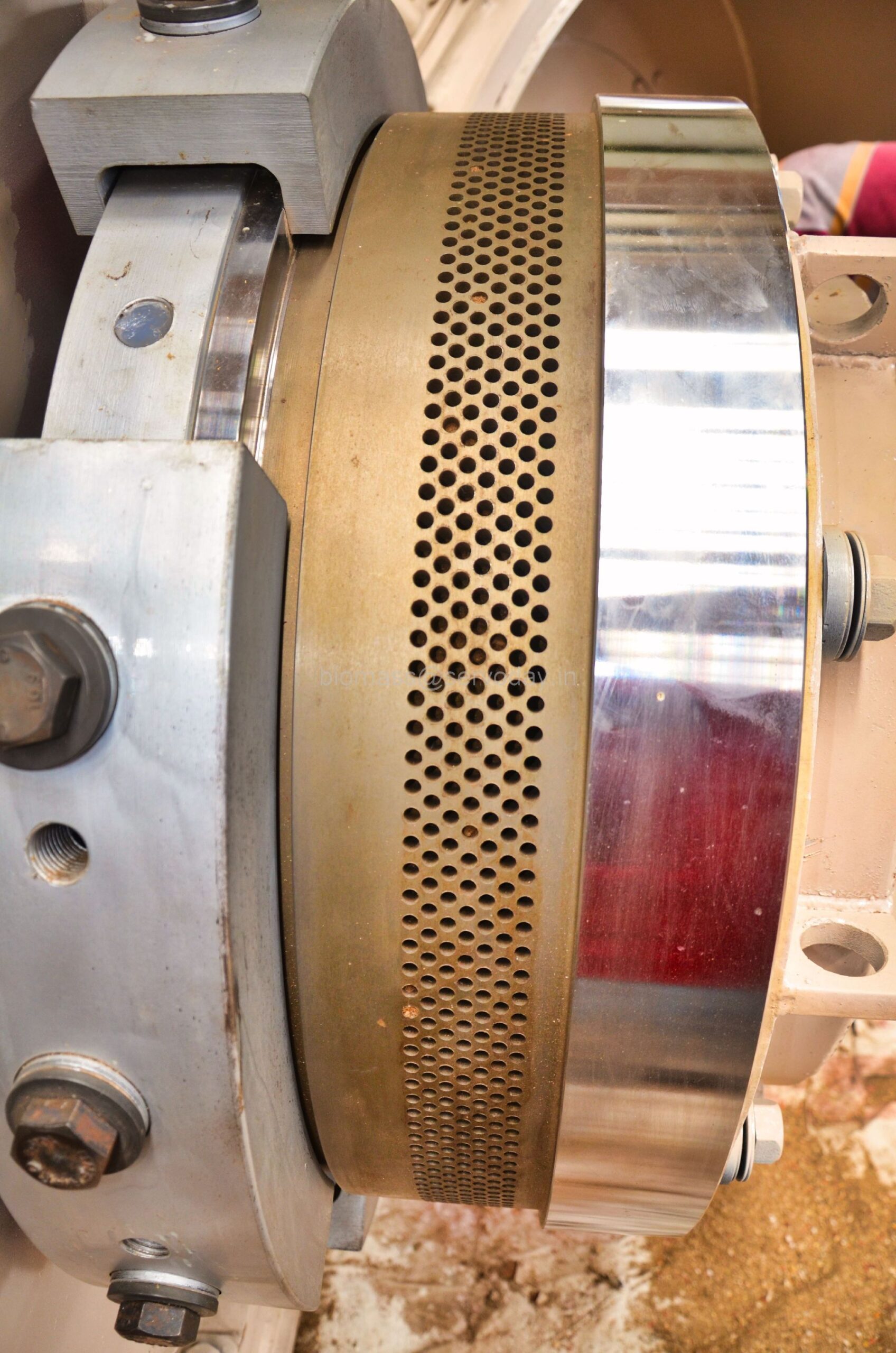

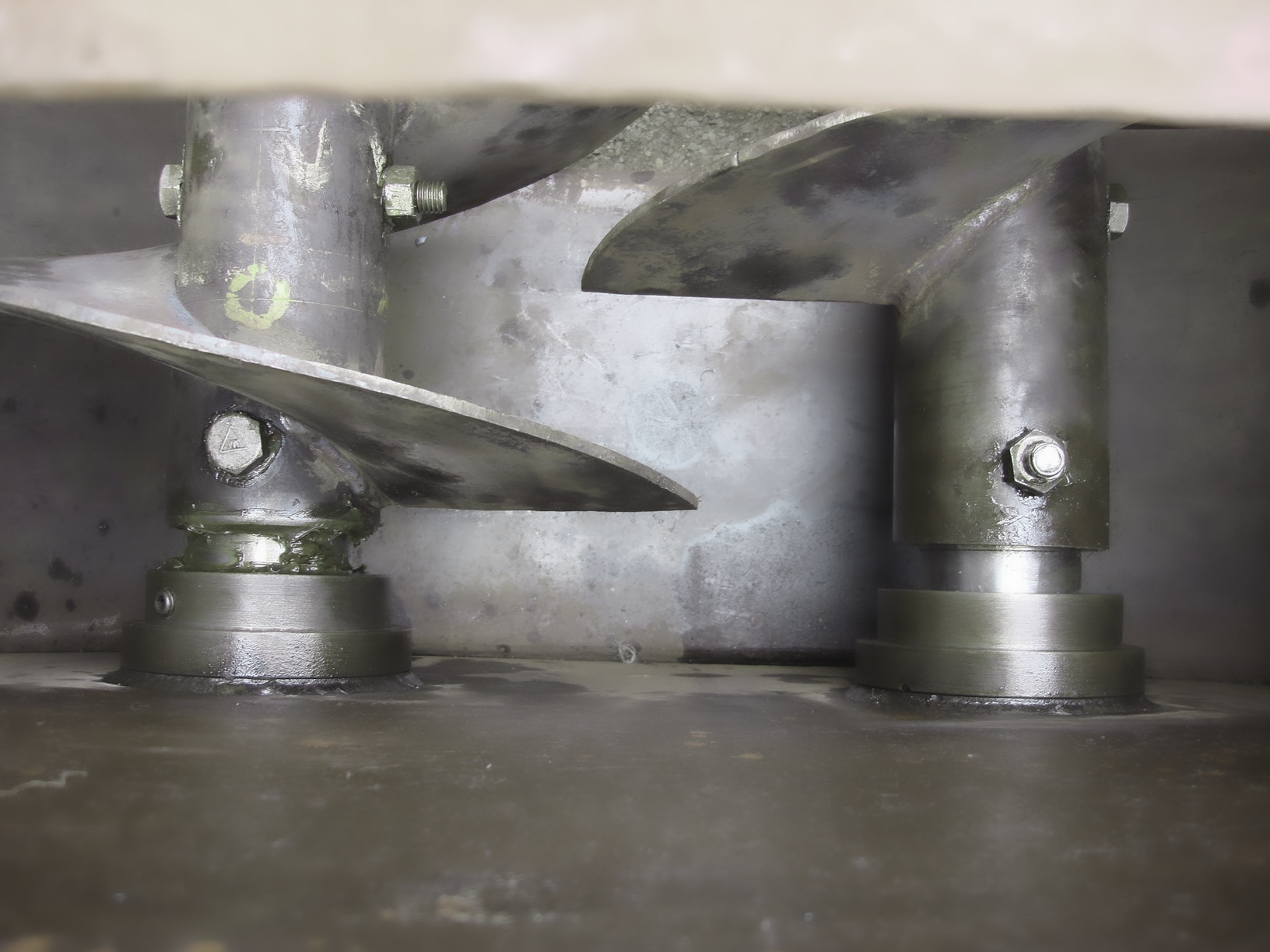

- Ring Die Design: The ring die design ensures consistent pellet quality, high compression, and efficient production.

- Heavy-Duty Construction: Built for 24/7 operation, the pellet mill is designed to withstand severe running conditions and reduce downtime.

- Gearbox with Pressurized Lubrication: Features a one-piece cast gearbox with pressurized oil lubrication, ensuring smooth operation and extended machine life.

- Automatic Grease System: Equipped with an automatic lubrication system that minimizes maintenance needs and ensures consistent performance.

Unique Aspects

- Dual Track Technology: Optional dual roller system for enhanced efficiency, reducing energy consumption while increasing pellet output per revolution(dual track).

- Continuous Operation: The design allows for continuous, 24-hour production under demanding conditions, making it highly reliable for industrial-scale pellet production.

- Multiple Feedstock Capability: The mill can process a wide variety of biomass feedstocks, providing flexibility for different raw materials.

Design Focus

- Durability and Efficiency: Designed with advanced engineering and built from heavy-duty materials to ensure long service life, even in harsh operating environments.

- High Capacity and Low Energy Consumption: Optimized to deliver high pellet output with minimal energy usage, providing both economic and environmental benefits.

- Automated Operation: Features like automatic lubrication reduce the need for manual intervention, allowing for efficient, round-the-clock operation.

Raw Materials

The Ring Die Pellet Mill is capable of processing a wide range of biomass materials, including:

- Wood Waste: Sawdust, wood chips, bamboo dust, forestry waste.

- Agricultural Residues: Rice husk, wheat straw, paddy straw, groundnut shells, sunflower stalks.

- Other Biomass: Bagasse, coir pith, coffee husk, jute waste, Napier grass, coconut shells.

Output Capacity

- Production Rate: 1-5 tons per hour, depending on the type of material being processed and the specific setup of the machine.