Air Aspiration System for Biomass Handling

upto 5 Tons Per Hour

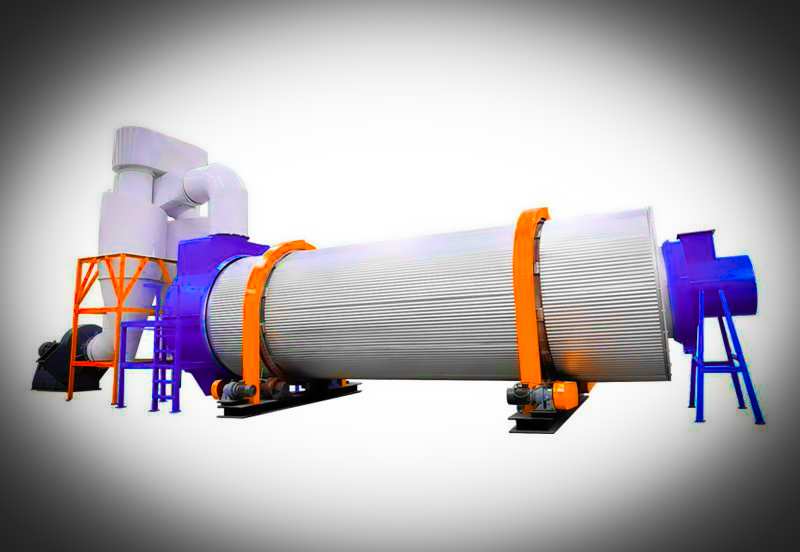

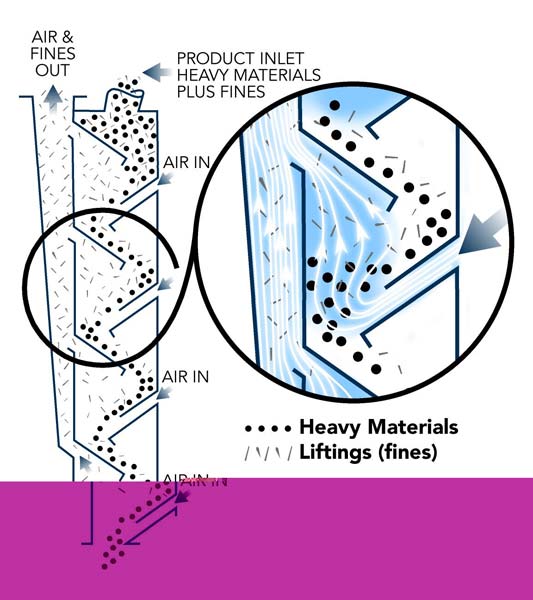

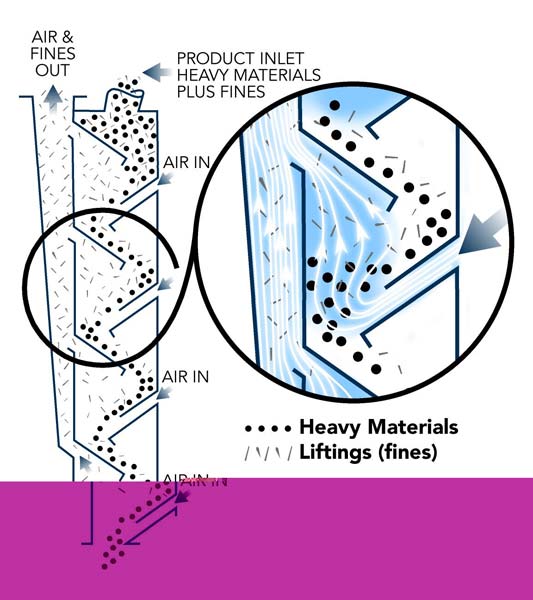

Introduction The Air Aspiration System is a critical component designed for handling a wide range of biomass materials in pellet production. It ensures efficient material handling by managing airflow and reducing dust, contributing to improved operational efficiency and product quality in biomass pellet plants. The system is fabricated using high-quality raw materials and is built […]