Introduction

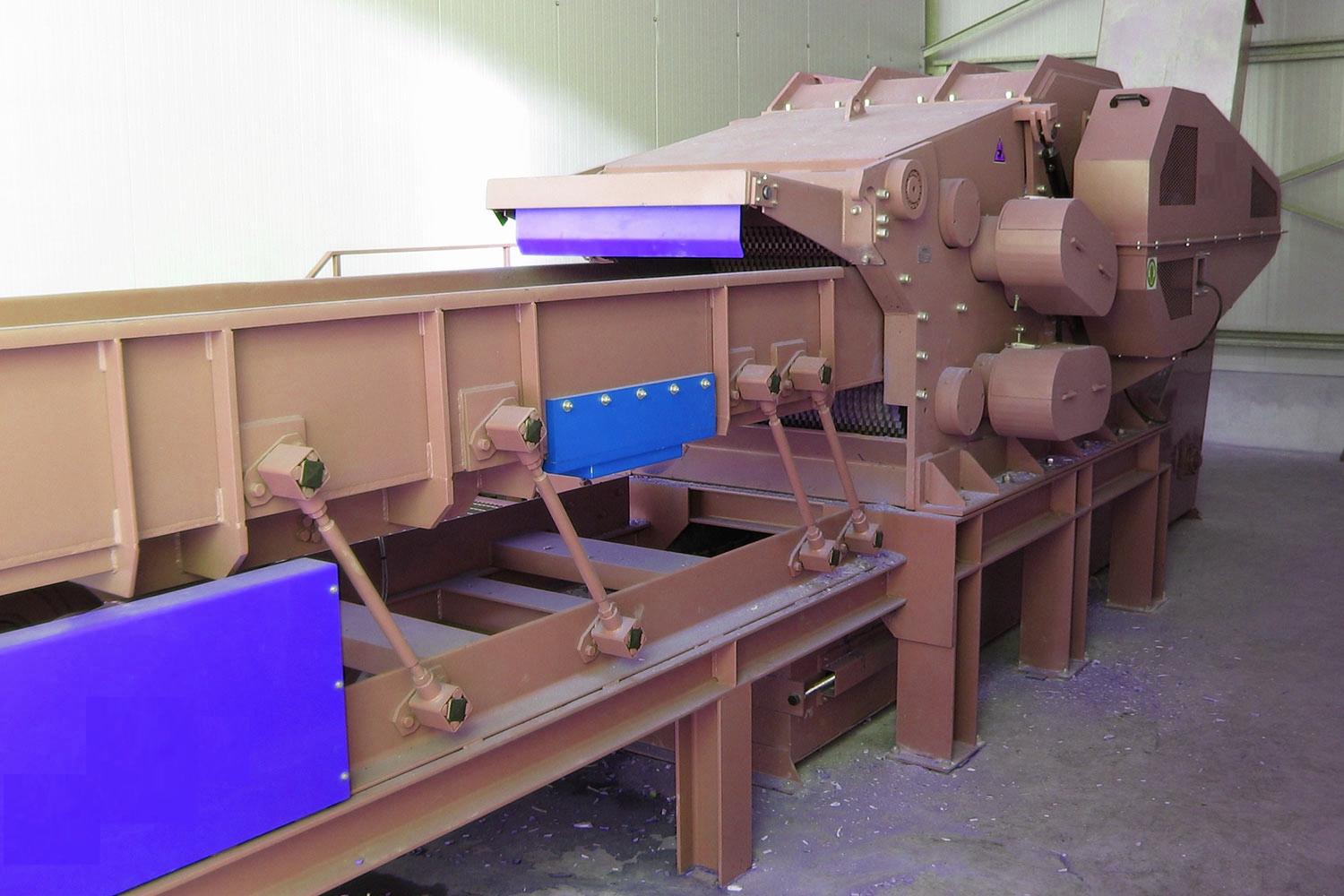

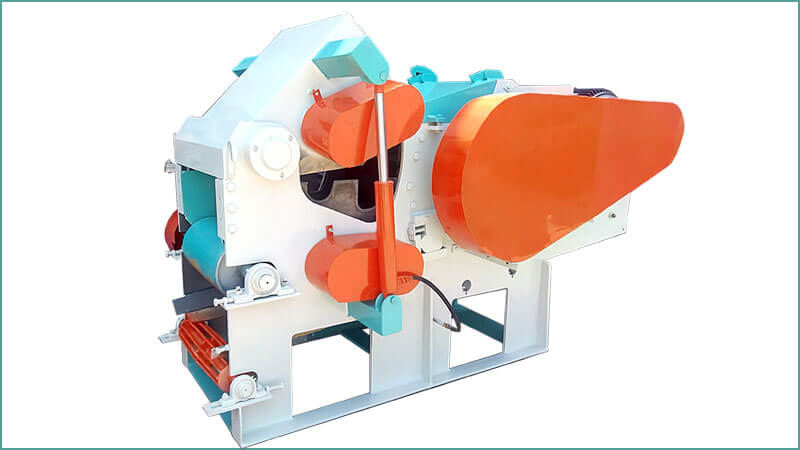

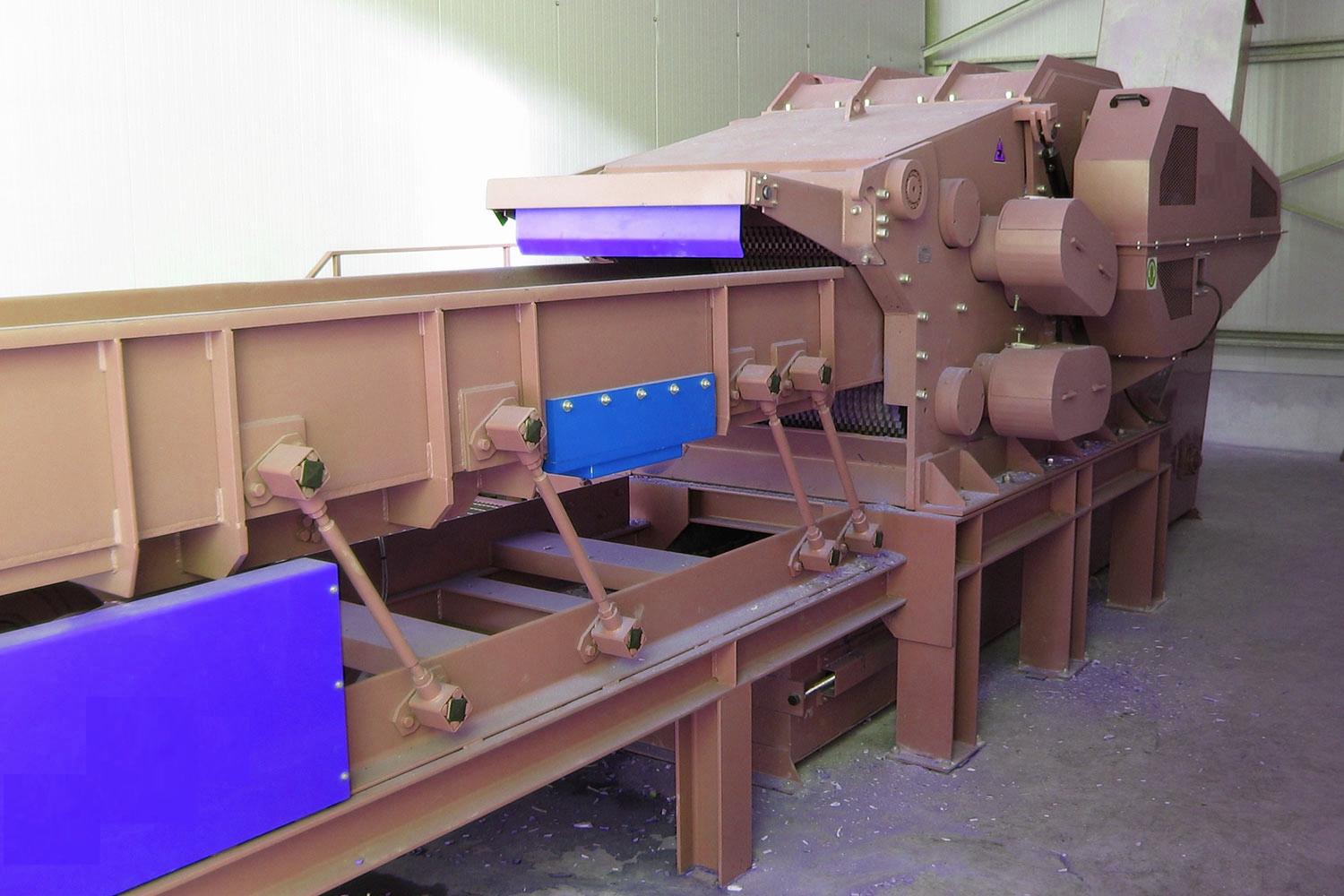

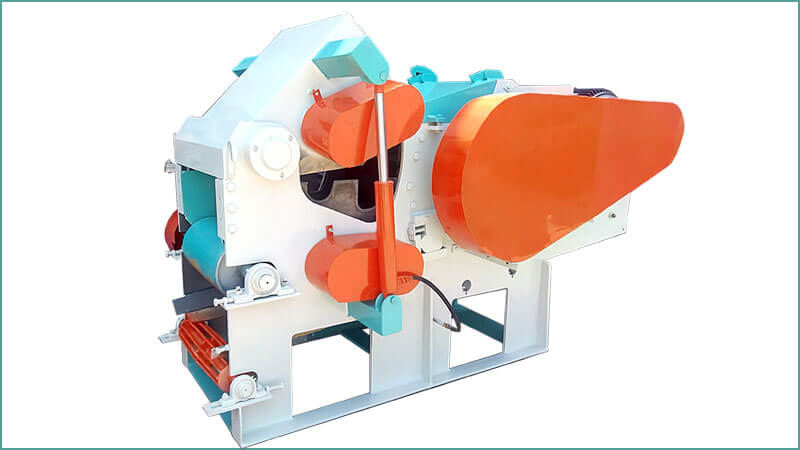

The Rotary Drum Chipper Shredder is a high-performance machine designed for breaking down wood and biomass materials into uniform-sized chips. Suitable for a range of applications, including wood biomass pellet production, particle board manufacturing, and as boiler fuel, the Rotary Drum Chipper Shredder provides an efficient solution for managing biomass waste and producing high-quality wood chips.

Overview

The Rotary Drum Chipper Shredder by Servoday is designed to process various wood and biomass feedstocks, including timber logs, sawmill waste, Empty Fruit Bunch (EFB), and wood residues. It comes equipped with a heavy-duty drum, multiple sets of blades, and wear-resistant HARDOX screens to achieve precise chip sizes. The shredder is available in different models with varying capacities from 3 to 45 tons per hour, depending on the type and density of input materials.

Purpose

The primary purpose of the Rotary Drum Chipper Shredder is to reduce the size of wood and biomass waste into consistent, high-quality chips that can be used for pellet production, particle board manufacturing, and energy generation. The machine helps in effectively managing timber and biomass waste, turning them into valuable raw materials for other processes.

Significance

- High Efficiency: Capable of processing up to 45 tons of biomass per hour, providing an effective solution for large-scale biomass and wood processing needs.

- Versatile Application: The shredder is suitable for various industries, including pellet production plants, particle board industries, and as a fuel source for boilers.

- Enhanced Waste Management: Helps reduce wood and biomass waste by converting them into uniform chips, thereby promoting sustainable practices.

Key Features

- Capacity Range: Available in capacities ranging from 3 TPH to 45 TPH, catering to different operational needs.

- Wear-Resistant Construction: Equipped with HARDOX steel screens that ensure durability and resistance to wear and tear during continuous operation.

- Heavy-Duty Self-Aligning Bearings: Built with robust bearings to minimize downtime and ensure smooth, reliable performance.

- Adjustable Chip Size: Features internal screens that allow the production of chips in different sizes according to the specific needs of downstream processing.

- Efficient Blade Design: The drum is fitted with sets of blades to effectively cut materials to the desired chip size.

Unique Aspects

- Multiple Models for Flexibility: Available in different models (e.g., SDC-6, SDC-15, SDC-30, SDC-40, and SDC-45), each designed to handle specific biomass capacities, ensuring flexibility for diverse processing requirements.

- Self-Cleaning Screens: The internal screens not only facilitate size control but also work efficiently in keeping the machine clean, reducing maintenance efforts.

- Multi-Feedstock Compatibility: Capable of processing various types of materials, including round wood, trimmings, veneer residuals, wooden poles, and EFB, making it versatile for multiple industries.

Design Focus

- Durable Build: The chipper shredder is constructed with a focus on longevity, using heavy-duty components that can withstand intensive industrial use.

- Consistent Chip Production: The tear-drop shaped design of the drum ensures consistent chip size and uniformity, which is crucial for efficient pellet production.

- Ease of Maintenance: Designed with easy access for maintenance, allowing operators to perform routine checks and replace parts without significant downtime.

Raw Materials

The Rotary Drum Chipper Shredder can process a wide variety of biomass materials, including:

- Wood Waste: Round wood, sawmill offcuts, slabs, trimmings, edges, veneer residuals, sleepers, wooden poles.

- Agricultural Residues: Empty Fruit Bunch (EFB), biomass residues from agriculture.

- Other Biomass: Timber logs, forestry waste.

Output Capacity

- Production Rate: Capable of handling between 3 and 45 tons per hour, depending on the model and the bulk density of the input materials.