Introduction

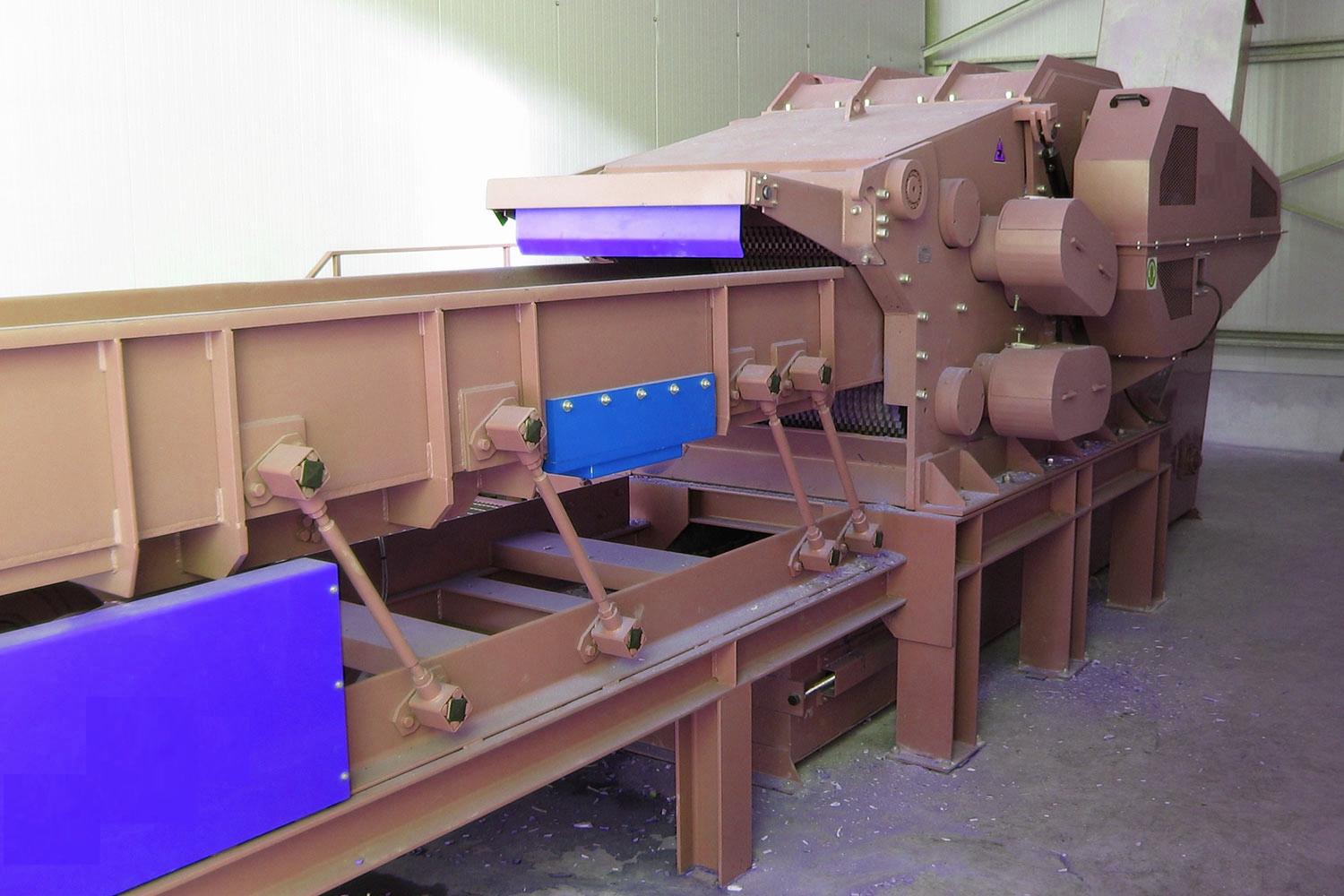

The Hydraulic Motion Floor is an advanced material handling system designed for biomass pellet production and biomass boiler fuel feed. This system consists of hydraulically operated panels or slats that move in a coordinated manner to push biomass materials, ensuring efficient storage, handling, and discharge. It is built for versatility and robustness, making it ideal for biomass storage facilities that require efficient movement of bulk materials.

Overview

The Hydraulic Motion Floor system by PelletIndia is designed to facilitate the handling and movement of biomass materials such as wood chips, bark, and pellets. The system uses hydraulic cylinders to move carriers across the storage floor, providing consistent material flow for storage, transportation, or direct feeding to a biomass boiler. It is designed to integrate with existing conveyor systems and maximize storage capacity through compact and uniform material distribution.

Purpose

The primary purpose of the Hydraulic Motion Floor system is to automate the movement of biomass materials within a storage area or production facility. It helps in evenly distributing biomass, managing the flow of material, and ensuring efficient discharge, which is essential for biomass pellet plants and boiler fuel feed systems.

Significance

- Efficient Storage Utilization: The Motion floor compacts and evenly distributes biomass, making efficient use of available storage space and maximizing capacity.

- Reduction in Manual Labor: Automation of biomass movement significantly reduces manual handling, leading to safer and more efficient operations.

- Seamless Integration: The system integrates well with conveyor systems for continuous movement of materials from storage to biomass processing facilities.

Key Features

- Hydraulic Movement Mechanism: Utilizes hydraulically operated slats that move in unison to transport biomass in a single direction, ensuring precise material handling.

- Multiple Carrier Systems: Equipped with various carrier systems that move directly on concrete floors via steel rails, ensuring stability and durability.

- Flow Control: Provides enhanced control over biomass movement, allowing operators to regulate material flow during loading, unloading, and storage.

- Low Maintenance: Designed for long-term use with minimal maintenance needs, reducing downtime and maintenance costs.

- Versatility: Suitable for handling different types of biomass materials, including wood chips, pellets, bark, and other bulk forms of biomass.

Unique Aspects

- Preventing Bridging and Blockages: The design helps prevent biomass from forming bridges or blockages, ensuring consistent flow during material extraction.

- Compatibility with Conveyor Systems: Can be easily integrated with conveyor systems to provide a seamless transition of materials from storage to processing.

- Customized Speed and Direction: The system allows for customizable speed and direction, offering flexibility in managing different types of biomass materials according to operational requirements.

Design Focus

- Uniform Material Movement: Emphasizes even distribution and movement of biomass materials to avoid segregation and uneven compaction.

- Safety and Efficiency: Focuses on enhancing safety through automation and ensuring energy-efficient material movement within storage facilities.

- Robust Construction: Built to operate in challenging industrial environments, using high-quality materials for reliability and durability.

Raw Materials

The Hydraulic Motion Floor system is capable of handling a wide range of biomass materials, including:

- Wood Waste: Wood chips, sawdust, bark.

- Agricultural Residues: Bagasse, rice husk, wheat straw.

- Other Biomass: Biomass pellets, Empty Fruit Bunch (EFB), forestry residues.

Output Capacity

- Handling Capacity: Capable of Motion bulk biomass materials at an adjustable speed, with the system customized to meet the storage and throughput requirements of biomass facilities.