Introduction

SYS Refurbished Pellet Mill is a high-quality pelletizing machine designed for producing biomass pellets, wood pellets, and feed. These pellet mills are fully refurbished by PelletIndia to meet a high standard of quality and reliability. Each mill undergoes extensive testing and a complete run-in at the factory to ensure long-lasting production capability.

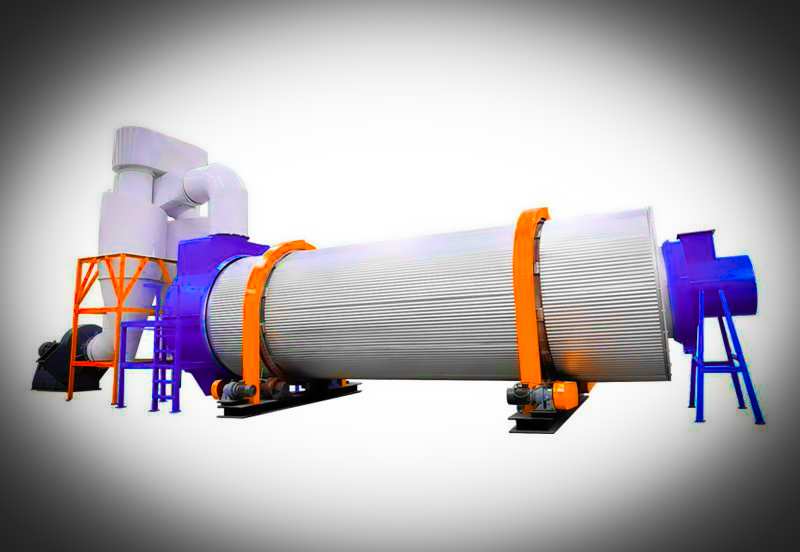

Overview

The SYS Refurbished Pellet Mill is part of a series of pellet mills that includes models like SYS 7900, SYS 7700, SYS 3000, and SYS 2000. These mills are refurbished to handle a wide range of biomass and feed materials, with capacities ranging from 1 to 5 tons per hour. They feature different die diameters, widths, and surface areas, ensuring versatility for various production requirements.

Purpose

The primary purpose of the SYS Refurbished Pellet Mill is to produce high-quality biomass and feed pellets. These refurbished mills are designed to be cost-effective and energy-efficient, offering an alternative to purchasing new pelletizing equipment while maintaining reliability and quality for consistent production.

Significance

- Cost-Effective Solution: Provides an affordable alternative to brand new pellet mills, making it accessible for producers looking to expand their operations without significant investment.

- High Efficiency: Designed for continuous production with high output, making it suitable for industrial-scale pellet production.

- Sustainable Choice: Refurbishing and reusing existing equipment contributes to a circular economy by reducing the need for new resources and extending the lifespan of machinery.

Key Features

- Capacity: Capable of producing between 1 and 5 tons per hour, depending on the model, suitable for both small and large-scale operations.

- High-Quality Refurbishment: All refurbished mills are thoroughly inspected, repaired, and run-in at the factory to ensure long-lasting performance.

- Die Variety: Models have various die diameters, ranging from 407 mm to 915 mm, and die widths from 57 mm to 356 mm, allowing customization based on production requirements.

- Motor Power: Equipped with electric motors ranging from 90 kW to 400 kW, providing the power needed for efficient pellet production.

- Suitable for Various Materials: The mills are designed to handle wood, biomass, and feed, providing versatility in pellet production.

Unique Aspects

- Fully Tested Refurbishment: Each mill is fully run-in and tested before delivery to ensure operational readiness and quality performance.

- Range of Models: A variety of models are available, including SYS 7900, SYS 7700, SYS 3000, and SYS 2000, each with different capacities and configurations, allowing buyers to select the best option for their needs.

- Upgraded Options Available: Some models come with advanced features like the Lineator, Enforcer, and Remote Sensor Monitoring (RSM) to improve performance, optimize operation, and provide remote diagnostic capabilities.

Design Focus

- Reliable and Durable Operation: Refurbished to meet high-quality standards, ensuring reliable and durable operation even in demanding production environments.

- Flexibility in Production: The different die configurations allow for flexibility in the type and size of pellets produced, catering to various industrial requirements.

- Energy Efficiency: Optimized for efficient energy use, ensuring that pellet production is both environmentally friendly and cost-effective.

Raw Materials

The SYS Refurbished Pellet Mill can handle a variety of materials, including:

- Wood Waste: Sawdust, wood chips, and other wood by-products.

- Agricultural Residues: Rice husk, wheat straw, paddy straw, bagasse.

- Feedstock: Various types of grains and other feed materials for livestock.

Output Capacity

- Production Rate: Depending on the model, the mill can produce between 1 TPH to 5 TPH, providing flexibility for different production volumes.