Introduction

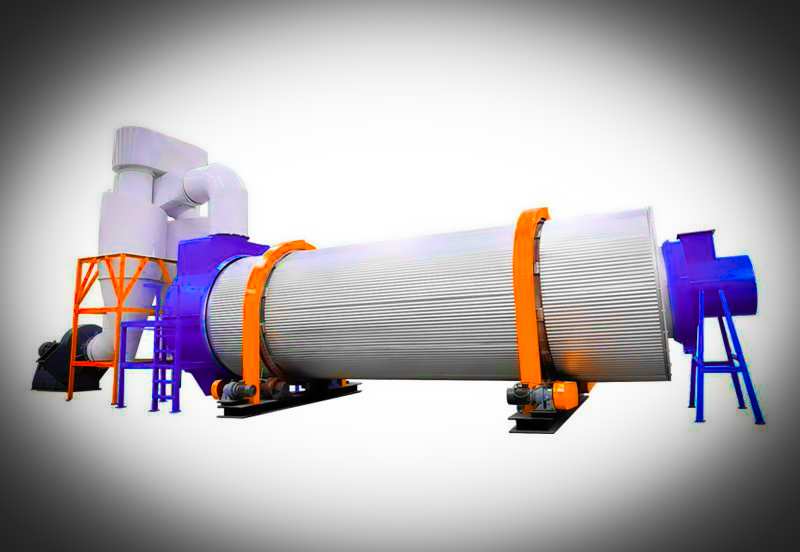

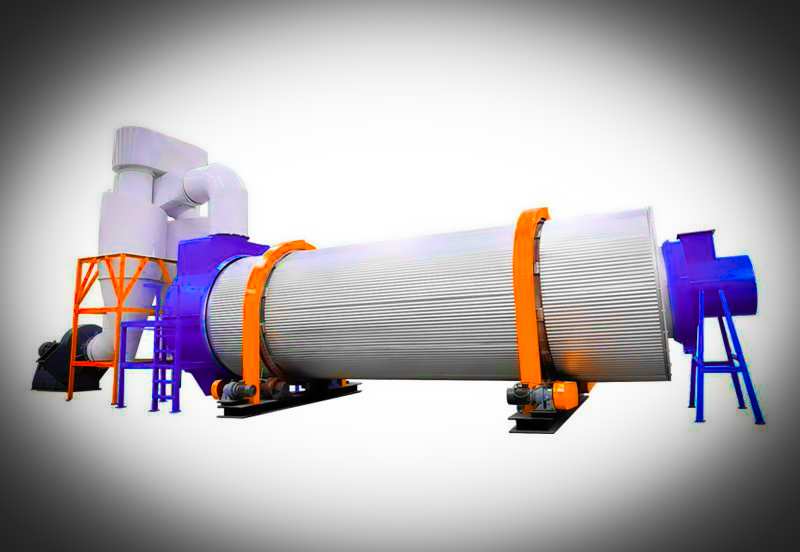

The Biomass Flash & Rotary Dryer is a high-efficiency drying solution designed to remove excess moisture from biomass materials such as wood chips, sawdust, wood powder, and other agricultural residues. It is a critical pre-treatment step in biomass pellet production, ensuring that materials have the proper moisture content for optimal pelletizing.

Overview

The Biomass Flash & Rotary Dryer combines flash drying and rotary drying techniques to ensure effective drying of biomass materials. It can process up to 10 tons per hour, providing flexibility and efficiency for both small and large biomass production facilities. The dryer is capable of reducing the moisture content of materials from as high as 60% down to the ideal level for pellet production, typically around 13-15%.

Purpose

The primary purpose of the Biomass Flash & Rotary Dryer is to prepare raw biomass materials for pellet production by reducing their moisture content. Proper moisture control is essential for efficient pelletizing, as it directly affects pellet quality, durability, and combustion efficiency.

Significance

- High Drying Efficiency: Ensures that biomass materials are dried evenly and efficiently, enhancing their suitability for pellet production.

- Optimal Moisture Control: By reducing moisture to ideal levels, the dryer supports the production of high-quality, durable pellets.

- Energy Savings: Designed for high thermal efficiency, allowing for significant energy savings in the drying process.

Key Features

- Capacity: Capable of processing up to 10 tons of biomass per hour, making it suitable for medium to large-scale operations.

- Large Drying Intensity: The flash drying method disperses materials effectively, increasing the drying surface area and enhancing efficiency.

- Short Drying Time: The contact time between materials and hot air is brief (0.5 to 5 seconds), preventing overheating and preserving the quality of heat-sensitive materials.

- High Thermal Efficiency: Uses co-current drying, where materials and hot air flow in the same direction, allowing for efficient heat transfer and high drying temperatures.

- Wide Application: Suitable for drying a variety of biomass materials, including wood chips, sawdust, wood powder, and even agricultural residues.

Unique Aspects

- Combination of Flash and Rotary Drying: The combination allows for high flexibility in handling materials of varying moisture levels and particle sizes, ensuring efficient drying performance.

- Minimal Space Requirement: The compact design requires less space compared to traditional drying systems, making it suitable for facilities with limited space.

- Versatile Heat Sources: The dryer can operate using various heat sources, such as fuel stoves, gas stoves, coal stoves, or steam heat exchangers, allowing flexibility based on available energy resources.

Design Focus

- High Thermal Efficiency: Emphasizes the use of efficient heat transfer methods to reduce energy consumption while achieving optimal drying results.

- Consistent Quality Control: Designed to maintain consistent drying parameters to ensure that biomass materials are evenly dried, reducing variability in the final product.

- Robust and Durable Construction: Built with high-quality materials to withstand the rigors of continuous industrial use, ensuring long-term reliability.

Raw Materials

The Biomass Flash & Rotary Dryer can process a wide range of biomass materials, including:

- Wood Waste: Wood chips, sawdust, wood powder.

- Agricultural Residues: Corn cobs, rice husk, wheat straw.

- Other Biomass: Bagasse, bark, other fibrous plant residues.

Output Capacity

- Production Rate: The dryer can handle up to 10 tons per hour, depending on the moisture content and type of biomass material being processed.