Introduction

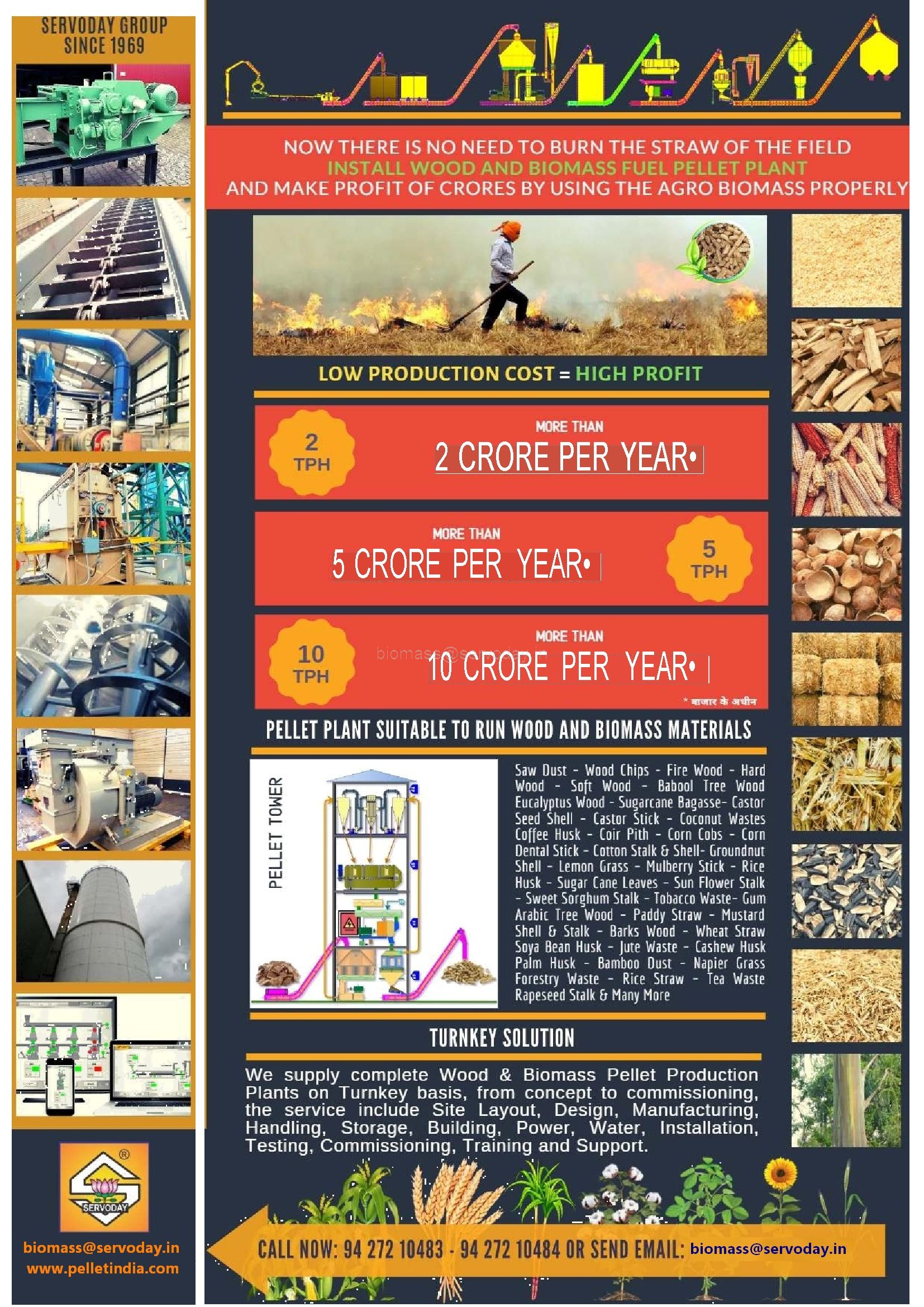

The Biomass Storage Silo is designed for the safe, efficient storage of wood pellets, wood chips, and other biomass materials. It provides a flexible storage solution for various biomass production facilities, ranging from small-scale operations to large industrial settings. The silos are built to ensure the integrity of the stored materials, prevent hazards, and maintain the quality of biomass products.

Overview

The Biomass Storage Silo is engineered to handle various biomass materials, including wood chips and pellets, from species like Pine, Cedar, Fir, Spruce, Hemlock, Teak, Rose, Oak, Maple, Mango, Cherry, and Walnut. The storage solution provides a range of capacities from 1 ton to 1000 tons, designed to comply with the specific requirements of biomass production plants and other related industries.

Purpose

The primary purpose of the Biomass Storage Silo is to provide a reliable storage solution for bulk biomass materials. It aims to maintain the quality of biomass by ensuring proper temperature and moisture control, thus preventing material degradation and ensuring smooth operations during pellet production or biomass processing.

Significance

- Safe Storage Solution: Provides an environment that minimizes risks related to moisture, mold, and fire, ensuring safe and long-term storage of biomass materials.

- Versatile Application: Suitable for different biomass materials, including wood chips, feed, and pellets, making it ideal for a variety of applications in the biomass and renewable energy sector.

- High Capacity: Offers storage capacities ranging from 1 ton to 1000 tons, catering to the needs of both small and large-scale biomass production facilities.

Key Features

- Flexible Storage Capacity: Available in a wide range of capacities from 1 ton to 1000 tons, customizable to meet specific production requirements.

- Material Handling Compatibility: Designed for storing biomass such as wood chips, wood pellets, and other biomass materials used in production plants.

- Durable Construction Materials: Built from stainless steel (SS) or mild steel (MS), ensuring durability and resistance to harsh environmental conditions.

- Ventilation and Aeration Systems: Equipped with proper ventilation and aeration systems to prevent condensation and maintain consistent pellet quality.

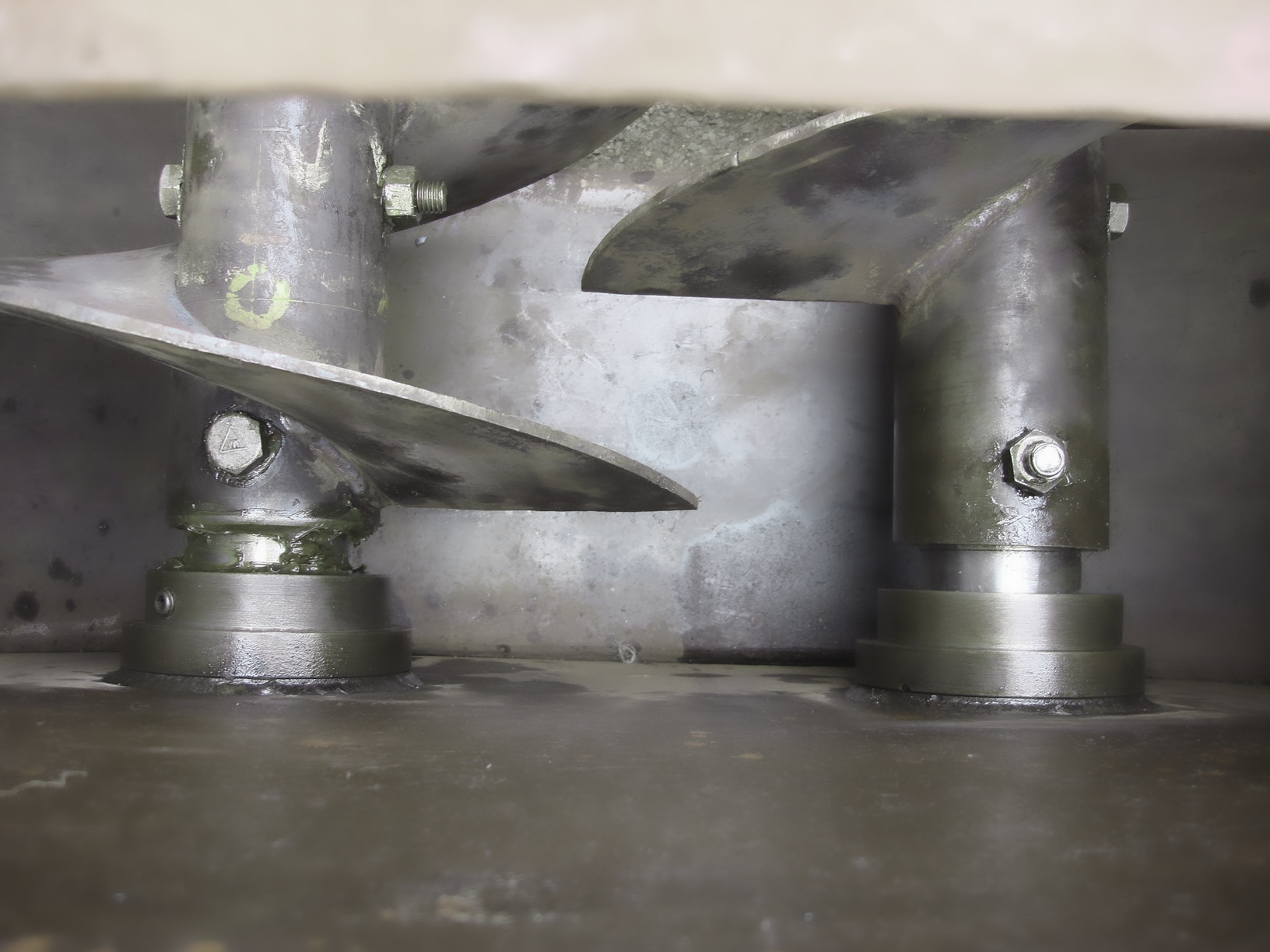

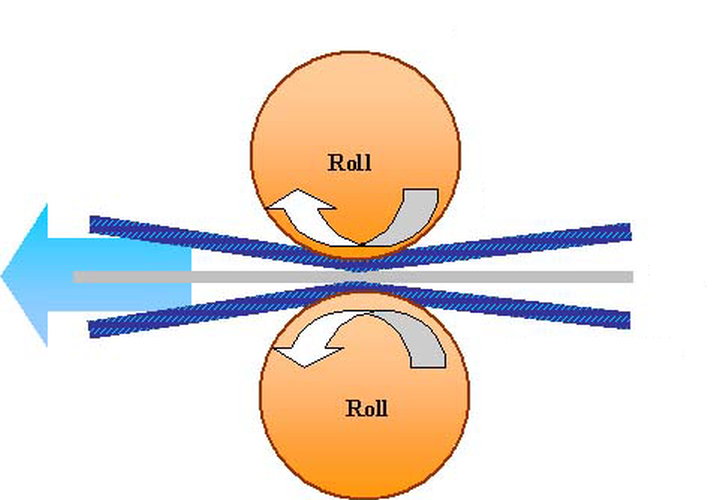

- Efficient Discharge System: Features a discharge mechanism like screw conveyors or augers for controlled material withdrawal, ensuring minimal pellet breakage.

- Safety Measures: Incorporates safety features such as dust control systems, reinforced structure, access platforms, and safety railings for secure operation.

Unique Aspects

- Customizable Design: The silo can be tailored to meet specific plant requirements, including material type, capacity, and integration with other biomass handling systems.

- Environmental Considerations: Features for dust control and airtight sealing help maintain environmental safety standards, while reducing material loss due to environmental factors.

- Moisture Control: Special attention is given to controlling moisture content through ventilation and insulation, ensuring that biomass materials remain intact and of high quality during storage.

Design Focus

- Safety and Durability: The silos are designed to withstand environmental stress, heavy loads, and adverse weather conditions, providing safe and secure storage for biomass.

- Efficient Material Flow: Focused on efficient material handling, the silos feature systems that facilitate smooth loading, unloading, and continuous flow to prevent blockages.

- Scalable Solution: The modular design allows scalability to accommodate increased production demands, making it suitable for expanding operations.

Raw Materials

The Biomass Storage Silo is used to store a wide range of biomass materials, including:

- Wood Types: Pine, Cedar, Fir, Spruce, Hemlock, Teak, Rose, Oak, Maple, Mango, Cherry, Walnut.

- Biomass Pellets: Wood pellets, feed pellets, and other biomass materials.

- Wood Chips and Agricultural Residues: Biomass chips and other forms of agricultural by-products used in pellet production.

Output Capacity

- Storage Capacity: Offers storage solutions with capacities ranging from 1 ton to 1000 tons, designed to meet various biomass production and storage needs.