Introduction

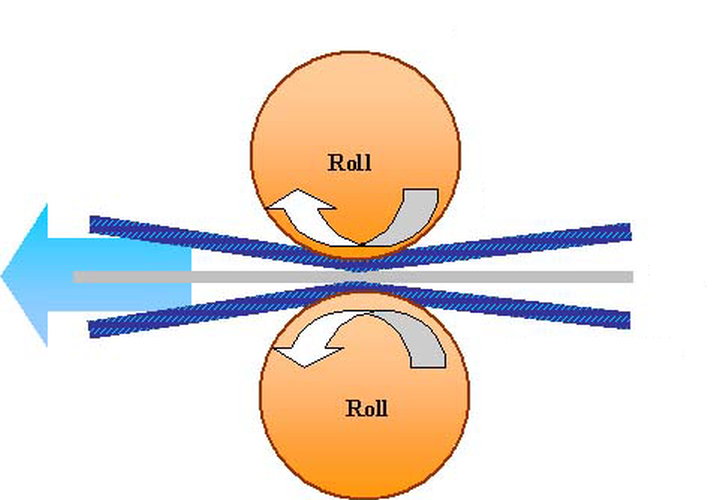

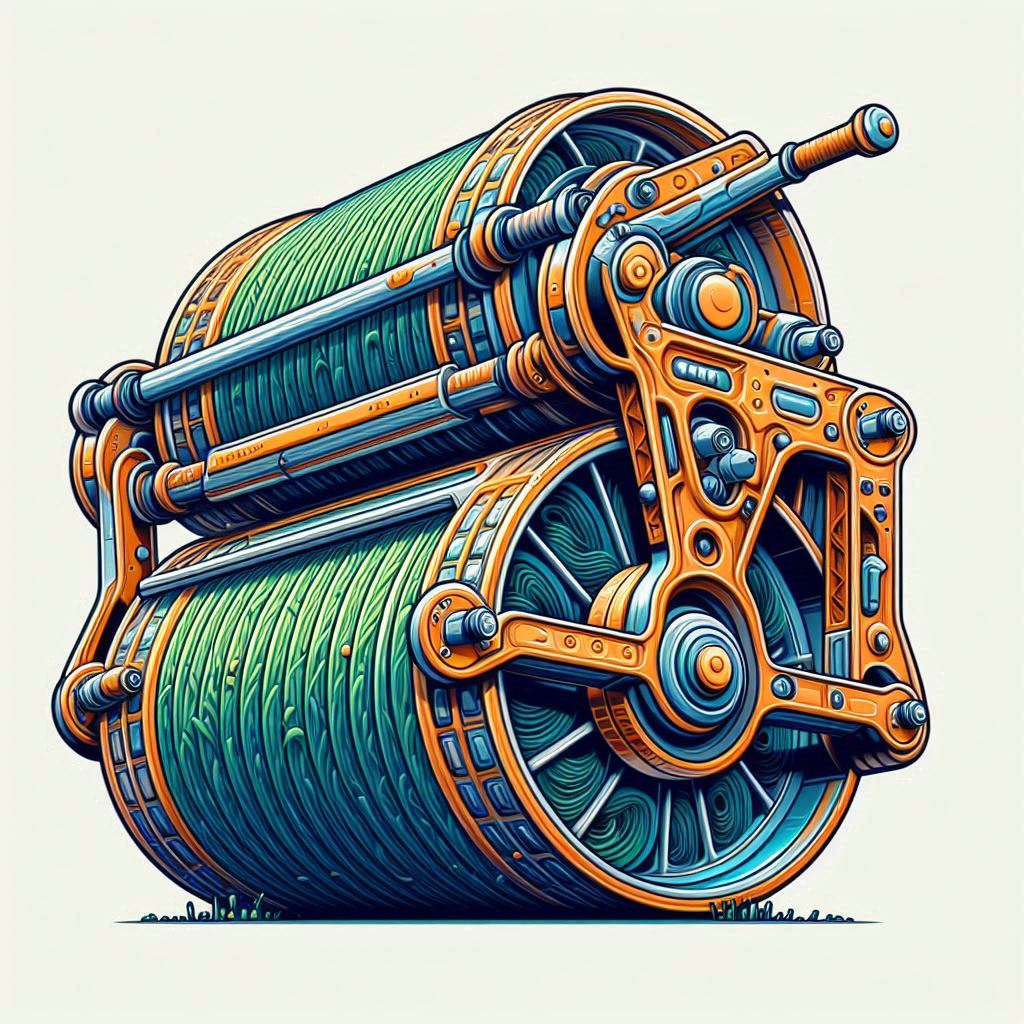

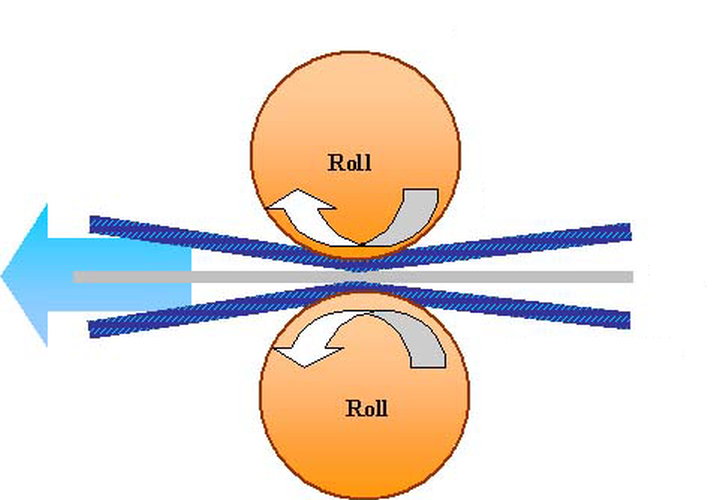

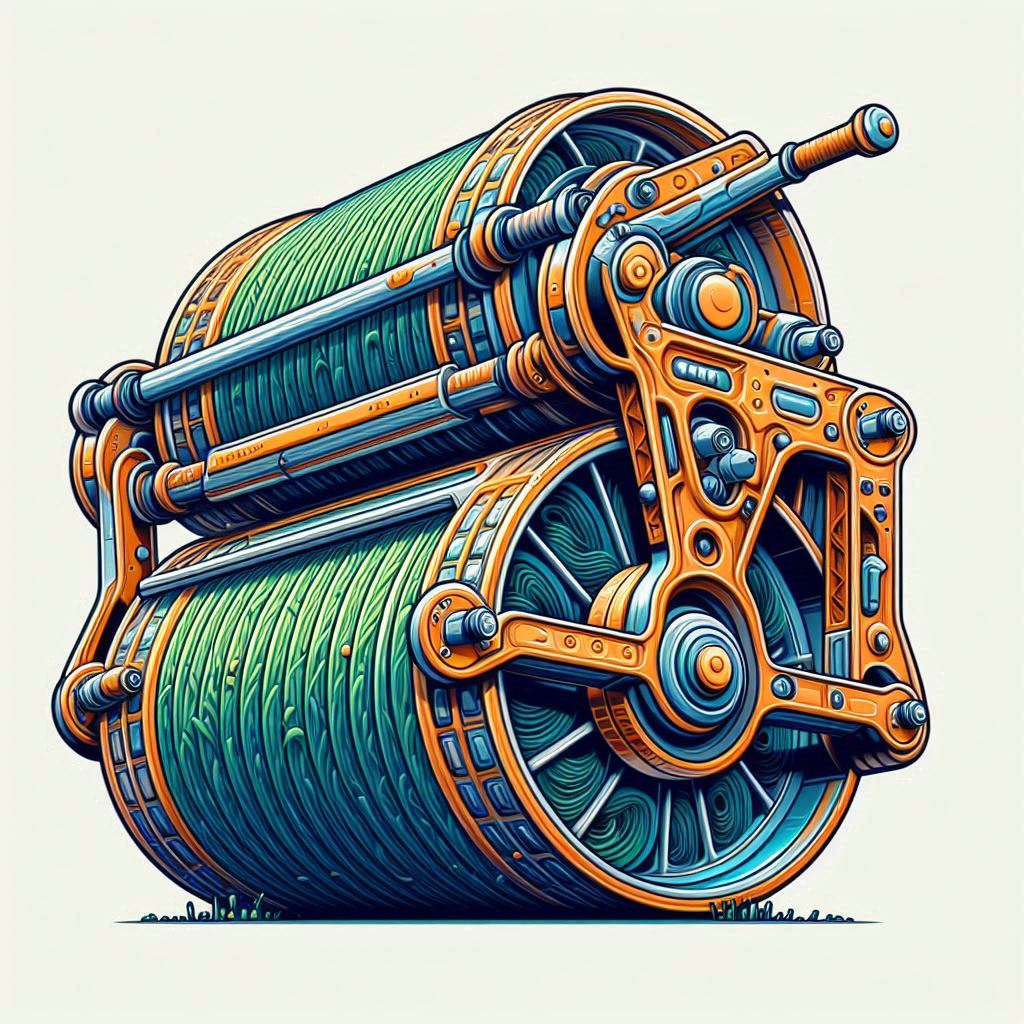

The Napier Grass Press Roll is an advanced dewatering technology designed to remove excess moisture from Napier Grass, enhancing its suitability for downstream biomass processing. This system is crucial for improving the calorific value of Napier Grass and preparing it for efficient pelletization, making it a key component in the renewable energy industry.

Overview

The Napier Grass Press Roll is engineered to efficiently reduce moisture content by up to 30%, enhancing the usability of Napier Grass for biomass energy production. It has a robust and reliable design that can handle large-scale operations with a capacity of up to 10 tons per hour. This press roll is built for versatility, adaptable to both small and large biomass processing facilities, making it a vital part of biomass pellet plants and biofuel production.

Purpose

The primary purpose of the Napier Grass Press Roll is to reduce the moisture content of Napier Grass to optimize it for biomass energy production. Removing excess moisture helps in reducing energy consumption during drying and pelletization, which ultimately leads to enhanced biomass quality and improved efficiency in subsequent processing stages.

Significance

- Enhanced Biomass Quality: By reducing moisture content, the press roll significantly enhances the calorific value of Napier Grass, making it more suitable for energy production.

- Reduced Drying Energy Consumption: Pre-drying using the press roll reduces the energy required for further drying, resulting in significant energy savings.

- Versatile Applications: Suitable for use in various biomass processing operations, including pelletization, biofuel production, and agricultural residue management.

Key Features

- Moisture Removal Efficiency: Capable of removing up to 30% moisture from Napier Grass, optimizing it for further processing.

- High Capacity: Can process up to 10 tons of Napier Grass per hour, suitable for both small-scale and large-scale biomass facilities.

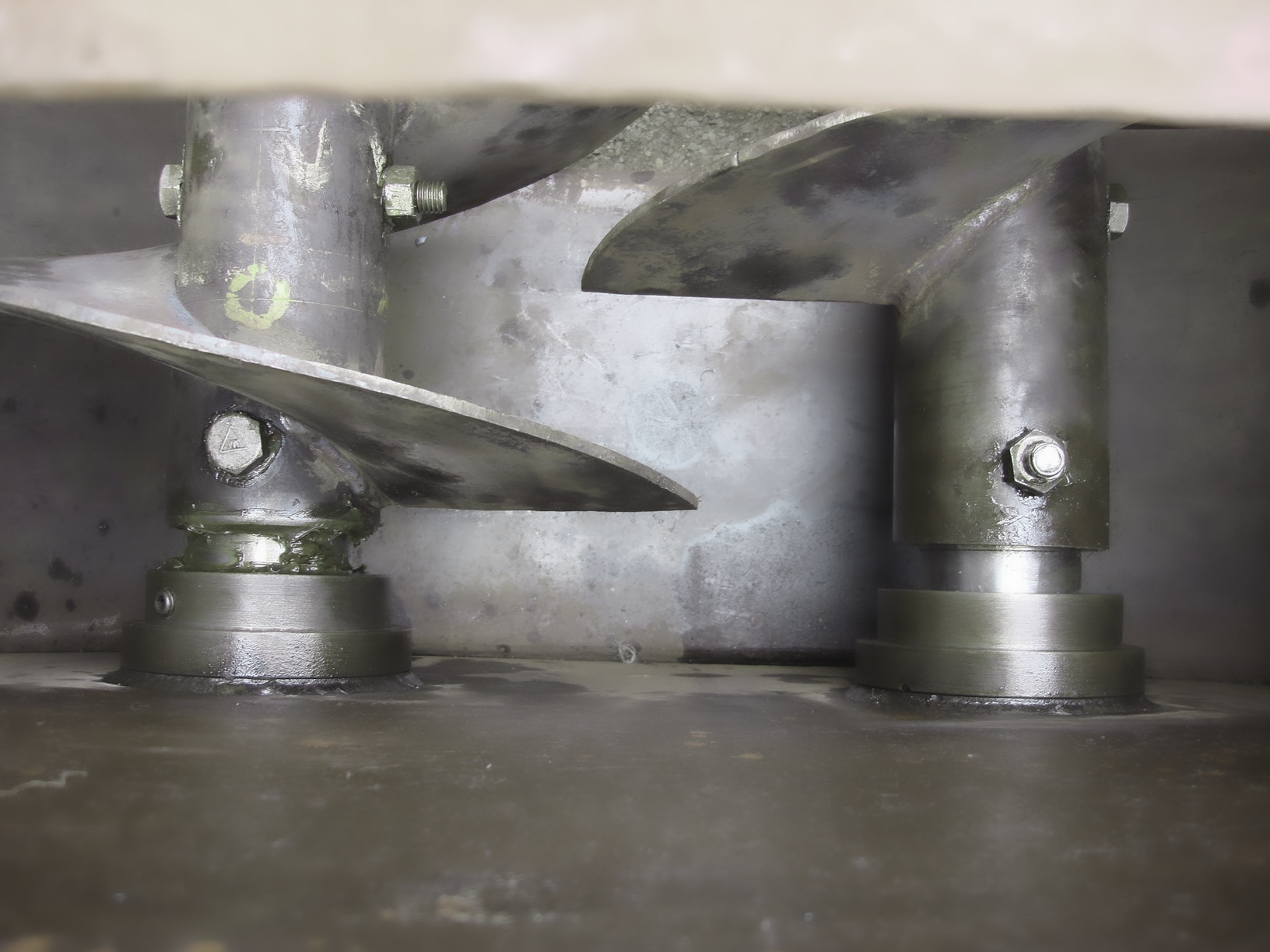

- Robust Design: Constructed from high-strength materials to withstand demanding operational conditions, ensuring continuous operation with minimal downtime.

- Adaptability: The press roll system is designed to be versatile, accommodating different scales of operation and various fibrous biomass materials.

- Automation Options: Offers optional advanced control systems for enhanced operational efficiency, providing flexibility in managing moisture reduction.

Unique Aspects

- Industrial-Grade Reliability: Built to provide consistent dewatering performance even under demanding operational conditions, making it reliable for industrial use.

- Energy Savings: The reduction in moisture content before drying leads to lower energy consumption during pelletization, providing significant cost savings.

- Suitable for Diverse Operations: Adaptable for use in different industries, from small farms to large biomass pellet production facilities, ensuring versatility.

Design Focus

- Optimized Dewatering Efficiency: The system is designed to maximize moisture removal while maintaining the structural integrity of the biomass.

- Durability for Heavy Use: Made from high-strength materials to ensure long-lasting operation in challenging environments.

- Scalable Capacity: Designed to cater to varying operational scales, allowing adaptability for different biomass production setups.

Raw Materials

The Napier Grass Press Roll is designed for use with:

- Napier Grass: A high-yield biomass resource used for pellet production and biofuel.

- Other Biomass Materials: Capable of handling other fibrous biomass, such as agricultural residues, depending on operational requirements.

Output Capacity

- Processing Capacity: Capable of processing up to 10 tons per hour, making it suitable for a range of biomass production scales.